First Rainwater Tanks for Stormwater Treatment

First Rainwater Treatment Systems and Tanks

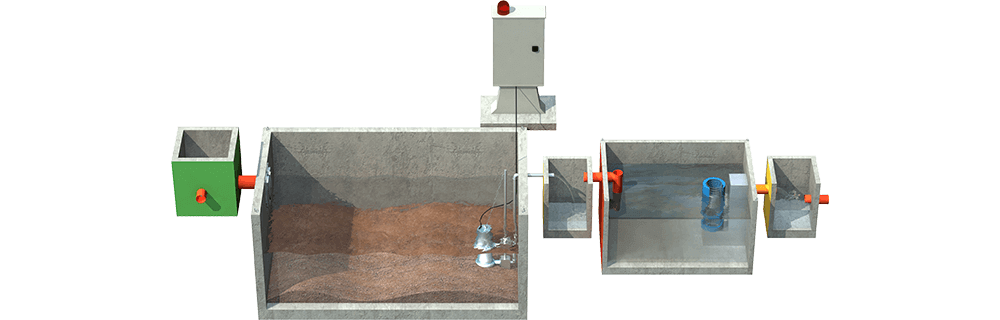

"Discontinuous" First Rainwater System

Storage and Delivery with Electric Pump to the Oil Separator. UNI EN 858-1 compliant, I class separator with coalescence filter

Introduction

First-flush rainwater management is one of the primary objectives for the protection of receiving water bodies. Specifically, these systems are designed for the temporary storage (using prefabricated tanks) of first-flush water, followed by timed and delayed delivery (approximately 48 hours) after the end of the weather event via a lifting electric pump to the subsequent treatment stage (Static oil separator with coalescence filter).

The use of these systems aims to reduce pollution toward surface water bodies and to mitigate flood peaks caused by heavy rainfall (cloudbursts).

First-flush rainwater treatment plants are sized based on their surface area in compliance with Regional or National technical regulations and European Directives. They consist of the following treatment phases: sand removal, oil separation with coalescence filters, lamella packs, and further finishing with activated carbon filters. In the treatment of first-flush and second-flush water, automatic cleaning systems can be installed during the sand sedimentation phase within the grit traps. Systems and equipment for rainwater treatment are also installed to facilitate disposal, thereby benefiting groundwater by preventing overflows in surface ditches, sewer overload during heavy rain, and malfunctions in urban wastewater treatment plants.

Features and Operating principle

The first-flush rainwater arriving from the sewage system, which collects all water from the streets and parking lots (transit areas) of the yard in question, is conveyed toward the storage tanks via a spillway or bypass manhole. This structure separates the first-flush water—"potentially polluted water identified as the first 5 mm"—from the second-flush water, which is theoretically clean and uncontaminated, and thus ready to be conveyed to the final discharge point.

First-flush water is temporarily stored in prefabricated reinforced concrete tanks where the sedimentation of sand and sludge occurs. The separation of first and second-flush water is ensured by a stainless steel floating non-return valve installed at the inlet of the storage tank. Subsequently (normally after 48, 72, or 96 hours), via a constant-flow submersible lifting electric pump, the water is sent to the oil separation treatment for light liquid removal (Table 3 discharge) or directly to the final receiving body.

In some cases, if the limits required by the manager are particularly restrictive (Table 4 discharge), further purification is necessary; therefore, quartzite and/or activated carbon filters are installed.

Downstream of the treatment, a sampling manhole of suitable size must always be installed to allow for sampling. The competent authority managing the final receiver (public sewer) may require the installation of a flow meter to account for the quantity of first-flush water discharged.

Applications

New urban developments, production, industrial, and craft areas, commercial sites, wire drawing and steel processing plants, fuel service stations, treatment of rainwater from yards used for material and aggregate storage, parking lots, motorhome rest areas, fuel depots, airports, port areas/docks, general sewage systems, rainwater disposal, and rainwater harvesting systems.

Proposed Accessories for Pollutant Control

The idSET-34 OS alarm system has been specifically designed to provide a unique solution for monitoring first-flush tanks or oil separators, particularly for water collection tanks in parking lots and service or rest areas.

Thanks to its two probes, the idSET-34 OS alarm system is able to monitor oil accumulation as well as sand and sludge deposits within the systems.

By positioning the probes at the desired levels, the system signals the exact moment to clean the tanks for both oil accumulation and the buildup of sludge, sand, or leaves on the bottom, allowing maintenance to be performed only when necessary.

The idSET-34 OS system uses an idOil-OIL probe to detect and signal the level of the water/oil separation interface inside the tank and an idOil-SLU probe to detect the presence of sand or sludge on the bottom. The idOil-OIL probe measures the difference between the electrical conductivity of water and that of oil.

The idOil-SLU probe determines the presence of sludge or sand using an ultrasonic sensor.

Main Sizing and Specific Configurations

National – Italy

Art. 113 of Legislative Decree No. 152 of April 3, 2006, Part III (Provisions on the protection of water from pollution) states that water must be regulated.

EU Directives No. 91/271/EEC (Urban Waste Water Treatment) and No. 91/676/EEC (Rainwater runoff and first-flush water), both transposed by the Italian state, declare that "..for the purpose of preventing hydraulic and environmental risks, the regions, following the opinion of the Ministry of the Environment and Protection of the Territory, shall regulate and implement:

a) forms of control for rainwater runoff discharges from separate sewer networks;

b) etc. Art. 2 Definitions V – “First-flush water”: the first 2.5 – 5 mm of rainwater runoff uniformly distributed over the entire drainage surface served by the drainage system.

For the calculation of the relevant flow rates, it is assumed that this value occurs over a period of 15 minutes; the runoff coefficients for the network are considered equal to 1 for paved or waterproofed surfaces.

Any cultivated surfaces are excluded from the aforementioned calculation.

The Lombardy Regional Law of March 24, 2006, No. 4, regarding the "Regulation of the disposal of first-flush water and the washing of external areas" in implementation of Article 52, paragraph 1, letter a) of regional law No. 26 of December 12, 2003 (BURL of March 28, 2006, No. 13, 1st ord. suppl.) decrees (some articles are reported):

Art. 3 (First-flush and washing water subject to regulation) The formation, conveyance, separation, collection, treatment, and discharge of first-flush water are subject to the provisions of this regulation if such water originates from:

a) drainage surfaces exceeding 2,000 sqm, calculated excluding roofs and green areas, belonging to buildings and installations where the following activities are carried out: petroleum industry, chemical industries, metal treatment and coating, skin and leather tanning and dyeing, pulp and paper production (paper and cardboard), tire production, textile companies performing printing, dyeing, and finishing of textile fibers, concrete production, intermodal areas, auto repair shops, body shops;

b) drainage surfaces belonging to buildings and installations where waste storage, collection and/or transformation centers, scrap yards, and vehicle demolition storage are carried out;

c) drainage surfaces intended for the loading and distribution of fuel and related and complementary operations at fuel service station points of sale;

d) drainage surfaces specifically or occasionally intended for the storage, loading, unloading, transfer, and general handling of substances referred to in Tables 3/A and 5 of Annex 5 of Legislative Decree No. 152 of April 3, 2006, Part III.

Art. 5 (Systems for the collection and conveyance of first-flush and washing water)

1) All surfaces referred to in Article 3 must be waterproof.

2) First-flush water and washing water, to be discharged into a surface water body or onto the soil or into the surface layers of the subsoil, must be sent to special watertight collection tanks, sized to hold a total of no less than 50 cubic meters per hectare of drainage surface (hereinafter first-flush tanks).

3) A dedicated collection and conveyance network must be assigned for rainwater runoff, equipped, in the cases referred to in paragraph 2, with a feeding system for the first-flush tanks that automatically excludes them once full; the network must be sized based on short-duration, high-intensity weather events characteristic of each area, assuming at least that the event occurs in fifteen minutes and that the runoff coefficient is equal to 1 for the drainage surface and 0.3 for any contiguous permeable surfaces, excluding uncultivated and agricultural surfaces from the calculation.

The penalty provided for those who do not comply with these legislative provisions is regulated by 152/2006 Part III Art. 133 paragraph 9 with a fine ranging from 1,500 to 15,000 euros, and for those who do not comply with Art. 113 paragraph 3 of the same decree, the criminal penalty stated in Legislative Decree 152/2006 Part III Art. 137 paragraph 9 applies, providing for imprisonment from 2 months to 2 years.

Emilia Romagna

The regional regulation currently in force (Regional Resolution of December 18, 2006, No. 1860 "Guidelines for the management of rainwater runoff and first-flush water in implementation of Regional Government Resolution No. 286 of 14/02/2005") defines a weather event as "one or more atmospheric precipitations, even if temporally separated, with a total height of 5 mm, occurring or succeeding at an interval of at least 72 hours from a previous and similar event." In particular, it defines first-flush water as the result of the runoff from uncovered waterproof surfaces, in relation to the activities carried out therein or the intended uses, which can be considered completed or exhausted within the timeframe defined for the assessment of first-flush water (5 mm).

Emilia Romagna Regulation D.G.R. 1860/2006 for the cities of Bologna, Piacenza, Parma, Reggio Emilia, Rimini, Forlì Cesena, Ferrara.

Abruzzo

The regional regulation currently in force (Regional Law No. 31 of 29-07-2010) for the cities of Chieti, L'Aquila, Pescara, and Teramo, regarding the management of rainwater runoff and first-flush water, defines a weather event as "one or more atmospheric precipitations, even if temporally separated, with a total height of 4 mm, occurring or succeeding at an interval of at least 72 hours from a previous and similar event." In particular, it defines first-flush water as the result of runoff from uncovered waterproof surfaces, in relation to the activities carried out therein or the intended uses, which can be considered completed or exhausted within the timeframe defined for the assessment of first-flush water (15 min). During rainy periods, rainwater falling on waterproof surfaces carries pollutants present on the ground; therefore, the resulting contaminated water can cause serious environmental damage if discharged into surface water bodies. Consequently, the regulation requires the separation of first-flush water from second-flush water, sending the latter directly to the final discharge point. Meanwhile, first-flush water must be sent to storage and, after 48-72 hours, conveyed to oil separation treatment for the removal of light liquids.

Puglia

This first-flush system differs from traditional ones because a coarse screening system must be installed upstream of the storage tank (for the storage of the first few millimeters of the weather event). Normally, this pretreatment is designed within a dedicated concrete manhole or even inside the bypass manhole made of vibrated reinforced concrete. The choice of the screen can be static/manual or automatic (with the aid of electromechanical equipment such as a Shaftless Screw Screen); this normally depends on the scale of the intervention and the type of water coming from the yard in question.

(REGIONAL REGULATION of December 9, 2013, No. 26 "Regulation of rainwater runoff and first-flush water").

Supply Specifications

Supply and installation of a batch-type First-Flush System mod. RAIN_ ______________, effective volume ___._ mc.

Sizing:

- ITALY NATIONAL REFERENCE Legislative Decree 152/06 (5 mm/sqm) up to surfaces of _____ sqm;

- EMILIA ROMAGNA Region D.G.R. 286/05 and 1860/06

Cf*=100 (low) up to surfaces of _____ sqm

Cf*=200 (medium) up to surfaces of _____ sqm

Cf*=300 (high) up to surfaces of _____ sqm;

- ABRUZZO Region L.R. 31/10 (4 mm/sqm) up to surfaces of _____ sqm.

The system consists of:

- n._ First-Flush Storage Tank(s) mod. VACM__________ dimensions ___x____xh___ cm (cover excluded);

- DN___ Non-return Flap Valve at the inlet mod. VALVCLAPETDN___ made of AISI 304 stainless steel installed in the tank (alternatively, DN___ Non-return Floating Valve mod. VALVGALINOX___ made of AISI 304 stainless steel);

- Integrated automatic first-flush disposal system (Lifting Station kit) code KITPP1P, complete with n. 1 submersible lifting electric pump mod. GQS50-8 400V 0.55W 1.6A with relevant PVC piping, management and control panel with PLC logic programmable directly via the attached touchscreen display, level sensors installed in the tank, external rain sensor, and optical/acoustic alarm;

- Static Oil Separator / Light Liquid Separator mod. DISCE_______ CE marked, Class I compliant with UNI EN 858 standard with certification from an independent third-party body as indicated in Appendix D point D.2.1 of the UNI EN 858 standard, NS ___ l/sec, dimensions ___x___xh___ cm (cover excluded), complete with flow deflector and automatic closing device with floating shutter, including a removable coalescence filter made of polyester-based polyurethane foam with a defined and uniform hole structure having a porosity of 10 ppi (pores per inch), complete with a removable stainless steel AISI 304 basket.

Prefabricated structures specifications:

- Produced in DECLARED SERIES and with UNI EN ISO 9001 and ISO 45001 management systems;

- Compressive strength class C45/55 (RCK >55 N/mm²);

- Exposure classes XC4, XS3-XD3, XF1, XA2;

- GREESMIX5® steel fibers (where structurally required);

- IDROCONCRETE 1200® integral system (if requested);

- Certificate of conformity for prefabricated elements made with CE certified materials and recycled content according to the requirements indicated in the Minimum Environmental Criteria (CAM);

- Chemical Resistance and Reaction to Fire certifications issued by an external body according to UNI EN standards;

- Reinforced with vertical vibrated reinforced concrete pillars and horizontal stainless steel struts where required;

- Treated with Elastocolor protective elastomeric anti-cracking paint on the external concrete walls, featuring permanent high elasticity and high chemical resistance.

Treatment Guarantee:

Legislative Decree 152/06 Part Three, Annex 5, Table 3 "Discharge into Surface Waters", provided that the qualitative and dimensional values of the incoming flow to the treatment itself are respected and guaranteed, limited to the parameters of total suspended solids and total hydrocarbons.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

First Rainwater Treatment Systems Dimensions

Download Technical Drawings

Select Article Code to access the Data Sheet for the product.

(filter data by Regulation and optionally by Surface Area or Volume)

| Article Code |

Usable Volume F.R. (mc) |

Surface (sqm) | Inlet Pipes Diam. (mm) |

First Rainwater Tank | Static Oil Separator Code |

||||||||

| Italy** (5mm/qm) |

Emilia Romagna (F.R. Vol.+ Sedim.) |

Abruzzo (4mm/qm) |

External Dimensions (cm) |

Weight (ql) |

Cover Slab Weight (ql) |

||||||||

| Sludge Load | Width | Length | Height | h. 20 cm (D400) |

|||||||||

| (a) 100 |

(b) 200 |

(c) 300 |

|||||||||||

| RAIN_2,5 | 2,5 | 450 | 400 | 350 | 335 | 560 | 125 | 125 | 180 | 150 | 19,6 | 11,2 | DISCE2C-FC |

| RAIN_3,5 | 3,5 | 645 | 580 | 525 | 485 | 810 | 160 | 175 | 180 | 150 | 23,8 | 15,6 | DISCE2C-FC |

| RAIN_4,5 | 4,5 | 835 | 745 | 675 | 625 | 1.045 | 160 | 180 | 240 | 150 | 47,1 | 21,5 | DISCE2C-FC |

| RAIN_5,5 | 5,5 | 1.070 | 960 | 875 | 800 | 1.335 | 160 | 180 | 300 | 150 | 55,7 | 26,8 | DISCE2C-FC |

| RAIN_8,0_H200_S10 | 8,0 | 1.510 | 1.380 | 1.250 | 1.135 | 1.890 | 160 | 246 | 220 | 200 | 68,6 | 26,9 | DISCE2C-FC |

| RAIN_9,5_H200_S10 | 9,5 | 1.895 | 1.695 | 1.550 | 1.420 | 2.370 | 160 | 246 | 270 | 200 | 78,5 | 33,0 | DISCE2C-FC |

| RAIN_11,5_H200_S10 | 11,5 | 2.280 | 2.050 | 1.850 | 1.705 | 2.850 | 160 | 246 | 320 | 200 | 88,2 | 39,1 | DISCE2C-FC |

| RAIN_12,5_H250_S10 | 12,5 | 2.435 | 2.160 | 1.975 | 1.810 | 3.040 | 200 | 246 | 270 | 250 | 91,1 | 33,0 | DISCE3C-FC |

| RAIN_15,0_H250_S10 | 15,0 | 2.925 | 2.620 | 2.400 | 2.195 | 3.655 | 200 | 246 | 320 | 250 | 102,3 | 39,1 | DISCE3C-FC |

| RAIN_17,5_H250_S10 | 17,5 | 3.420 | 3.060 | 2.800 | 2.560 | 4.270 | 200 | 246 | 370 | 250 | 113,4 | 45,2 | DISCE3C-FC |

| RAIN_20,0_H250_S10 | 20,0 | 3.910 | 3.500 | 3.175 | 2.910 | 4.885 | 200 | 246 | 420 | 250 | 131,1 | 51,3 | DISCE3C-FC |

| RAIN_22,0_H250_S10 | 22,0 | 4.360 | 3.920 | 3.575 | 3.265 | 5.450 | 200 | 246 | 470 | 250 | 142,3 | 57,4 | DISCE3C-FC |

| RAIN_24,5_H250_S10 | 24,5 | 4.850 | 4.345 | 3.950 | 3.615 | 6.065 | 200 | 246 | 520 | 250 | 153,4 | 63,6 | DISCE3C-FC |

| RAIN_27,0_H250_S10 | 27,0 | 5.345 | 4.800 | 4.350 | 3.985 | 6.680 | 200 | 246 | 570 | 250 | 164,5 | 69,7 | DISCE3C-FC |

| RAIN_29,5_H250_S10 | 29,5 | 5.835 | 5.240 | 4.750 | 4.355 | 7.295 | 200 | 246 | 620 | 250 | 175,7 | 75,8* | DISCE3C-FC |

| RAIN_32,0_H250_S10 | 32,0 | 6.325 | 5.685 | 5.175 | 4.730 | 7.910 | 200 | 246 | 670 | 250 | 193,4 | 81,9* | DISCE3C-FC |

| RAIN_34,0_H250_S10 | 34,0 | 6.780 | 6.095 | 5.550 | 5.080 | 8.475 | 200 | 246 | 720 | 250 | 204,5 | 88,0* | DISCE3C-FC |

| RAIN_36,5_H250_S10 | 36,5 | 7.270 | 6.545 | 5.925 | 5.430 | 9.090 | 200 | 246 | 770 | 250 | 215,7 | 94,1* | DISCE3C-FC |

| RAIN_39,0_H250_S10 | 39,0 | 7.760 | 6.970 | 6.350 | 5.805 | 9.700 | 200 | 246 | 820 | 250 | 226,8 | 100,2* | DISCE3C-FC |

| RAIN_41,5_H250_S10 | 41,5 | 8.255 | 7.420 | 6.750 | 6.185 | 10.315 | 200 | 246 | 870 | 250 | 238,0 | 106,3* | DISCE4-8C-FC |

| RAIN_44,0_H250_S10 | 44,0 | 8.745 | 7.865 | 7.150 | 6.550 | 10.930 | 200 | 246 | 920 | 250 | 255,7 | 112,4* | DISCE4-8C-FC |

| RAIN_45,5_H270_S10 | 45,5 | 9.005 | 8.100 | 7.350 | 6.735 | 11.255 | 200 | 246 | 870 | 270 | 249,5 | 106,3* | DISCE4-8C-FC |

| RAIN_46,0_H250_S10 | 46,0 | 9.195 | 8.260 | 7.500 | 6.870 | 11.495 | 200 | 246 | 970 | 250 | 266,8 | 118,5* | DISCE4-8C-FC |

| RAIN_48,0_H270_S10 | 48,0 | 9.540 | 8.575 | 7.800 | 7.145 | 11.925 | 200 | 246 | 920 | 270 | 268,1 | 112,4* | DISCE4-8C-FC |

| RAIN_48,5_H250_S10 | 48,5 | 9.690 | 8.695 | 7.900 | 7.245 | 12.110 | 200 | 246 | 1020 | 250 | 277,9 | 124,7* | DISCE4-8C-FC |

| RAIN_50,5_H270_S10 | 50,5 | 10.035 | 9.025 | 8.200 | 7.515 | 12.540 | 200 | 246 | 970 | 270 | 279,8 | 118,5* | DISCE4-8C-FC |

| RAIN_51,0_H250_S10 | 51,0 | 10.180 | 9.145 | 8.300 | 7.615 | 12.725 | 200 | 246 | 1070 | 250 | 289,1 | 130,8* | DISCE4-8C-FC |

| RAIN_53,0_H270_S10 | 53,0 | 10.570 | 9.505 | 8.625 | 7.905 | 13.210 | 200 | 246 | 1020 | 270 | 291,4 | 124,7* | DISCE4-8C-FC |

| RAIN_68,0_H270_S10 | 68,0 | 13.515 | 12.160 | 11.050 | 10.125 | 16.895 | 315 | 2x246 | 670 | 270 | 2x203,0 | 2x81,9* | DISCE4-8C-FC |

| RAIN_78,0_H270_S10 | 78,0 | 15.530 | 13.950 | 12.675 | 11.615 | 19.410 | 315 | 2x246 | 770 | 270 | 2x226,2 | 2x94,1* | DISCE4-8C-FC |

| RAIN_88,5_H270_S10 | 88,5 | 17.630 | 15.840 | 14.400 | 13.195 | 22.040 | 315 | 2x246 | 870 | 270 | 2x249,5 | 2x106,3* | DISCE4-8C-FC |

| RAIN_103,5_H270_S10 | 103,5 | 20.695 | 18.600 | 16.900 | 15.485 | 25.870 | 315 | 2x246 | 1020 | 270 | 2x291,4 | 2x124,7* | DISCE4-8C-FC |

| RAIN_114,0_H270_S10 | 114,0 | 22.800 | 20.500 | 18.625 | 17.065 | 28.495 | 400 | 3x246 | 770 | 270 | 3x226,2 | 3x94,1* | DISCE4-8C-FC |

| RAIN_129,5_H270_S10 | 129,5 | 25.880 | 23.275 | 21.150 | 19.375 | 32.350 | 400 | 3x246 | 870 | 270 | 3x249,5 | 3x106,3* | DISCE4-8C-FC |

| RAIN_144,5_H270_S10 | 144,5 | 28.840 | 25.935 | 23.575 | 21.595 | 36.050 | 400 | 3x246 | 970 | 270 | 3x279,8 | 3x118,5* | DISCE4-8C-FC |

| RAIN_152,0_H270_S10 | 152,0 | 30.380 | 27.315 | 24.825 | 22.740 | 37.975 | 400 | 3x246 | 1020 | 270 | 3x291,4 | 3x124,7* | DISCE4-8C-FC |

* Cover Slab divided into two parts

** Puglia Region: Grating system required upstream of the plant

The data reported is purely indicative

It is possible to have extensions (bottomless tanks) for all of our products

For Dimensioning with bigger volumes other than those reported in the table, please contact our Technical Department.

Emilia Romagna Regulation Reference

| Type of Processing/Activity | Coefficient Cf | |

| (a) Low | All rainwater collection areas where small amounts of silt produced by traffic or similar are present, namely collection basins in fuel storage areas and covered refueling stations. | 100 |

| (b) Medium | Refueling stations, manual car washes, component washing, bus washing areas. | 200 |

| (c) High | Washing systems for construction vehicles, construction machinery, truck washing areas, self-service car washes. | 300 |

Regional Regulations and Guidelines

Regulations regarding the enhancement and reuse of water resources for the protection of water from pollution:

RESOLUTION 1053 - 2003 R.G.R. No. 1053-03 EMILIA ROMAGNA:

REGIONAL GOVERNMENT RESOLUTION DECEMBER 18, 2006 No. 1860:

Urgent environmental regulations:

Urban waste water discharges, sewerage, and water bodies ATO 2 Central Lazio Rome:

CERTIFICATIONS AND REGULATIONS\LIGURIA\2010 ARPAL GUIDELINES FOR DOMESTIC DISCHARGES:

Urgent environmental regulations:

Regional Water Protection Plan:

Clarifications on Regulation No. 1 of February 20, 2006, regarding the regulation of rainwater runoff:

Regulation of domestic wastewater discharges or those assimilated to domestic:

Regulation of rainwater runoff and first-flush water:

Regional Water Discharge Regulation:

Regulation of discharges into public sewers and discharges from civil settlements not connected to public sewers:

Regional Water Protection Plan:

Provincial Consolidated Act on environmental protection against pollution:

Regional Government Resolution of May 7, 2019, No. 627 - Directive on wastewater discharges, approval and publication:

Regulations for the protection of water from pollution Regional Law No. 59 of August 24, 1982

R.G.R. No. 2884, 09_29_2009 (updated 2010) Technical Implementation Rules W.P.P. Annex A RGR of 01_27_2011:

Water Protection Plan - RGR No. 1534 of 11_03_2015:

Design guidelines for first-flush rainwater tanks

First-flush rainwater is defined as the initial runoff from each storm event preceded by at least 48 hours of dry weather, calculated for a rainfall depth of 5 mm uniformly distributed. The treatment methods for first-flush water and the identification of runoff and wash water from external areas are specified in Article 24 of the PTAR Implementation Rules.

- Activities referred to in Annex I of Legislative Decree February 18, 2005, No. 59 (Full implementation of Directive 96/61/EC concerning integrated pollution prevention and control); - Processing plants for mineral or synthetic oils not falling under the cases referred to in letter a) of Annex I of the previous point, and commercial storage facilities for the same substances;

- Intermodal areas intended for the exchange of goods and materials; - Tanning and dyeing of hides and leather;

- Production of pulp, paper, and cardboard;

- Tire production;

- Judicial custody of vehicles and motorcycles, limited to areas intended for crashed or damaged vehicles;

- Repair shops, body shops;

- Car washes.

For the external areas of fuel distribution stations, mainly contaminated by hydrocarbons of mineral origin, if the impossibility of installing a tank with storage and a Lifting Station is appropriately documented due to insufficient space, continuous flow systems may be provided as an alternative.

Systems providing continuous treatment of rainwater must ensure compliance with the emission limits set by national regulations and established in the authorization.

Given the impossibility of available purification technologies to zero out pollutant concentrations to the point of being undetectable in analytical tests, the provision in paragraph 6 of Article 24 of the Plan Rules: "hazardous substances pursuant to Directive 2000/60/EC must be absent in said discharges," is considered fulfilled by applying the provisions contained in Annex 5 to Legislative Decree 152/2006 regarding discharges to soil and surface waters.

Technology

First-flush rainwater treatment involves a system of screening, sand removal, and oil separation. The first-flush waters are conveyed via a bypass manhole (first-flush/second-flush water separator) into specific tanks called "First-flush tanks." The system consists of 3 distinct phases:

- Separating the initial polluted rainwater from the subsequent runoff (second-flush) using a storm overflow manhole with a weir wall.

- Temporarily accumulating the highly polluted first-flush waters—which wash over roads and yards—to allow for the sedimentation of solid substances during their temporary storage;

- Conveying the temporarily stored water to a treatment unit for hydrocarbon separation. In current practice, the first-flush waters are separated from subsequent ones and sent to the oil separator (NS Oil Separators) via an underground storage basin with a capacity sufficient to contain the entire volume of rainwater runoff resulting from the first 5mm of rain fallen on the drainage surface pertaining to the plant.

The basin is preceded by a separator manhole containing an internal weir over which the second-flush waters flow once the free water surface in the basin reaches the level of the weir crest.

A drainage pump is installed in the basin, automatically activated by the control panel via a microprocessor that processes the signal from a rain detection sensor installed on the manhole inlet pipe.

At the end of the rainfall, the sensor sends a signal to the control panel, which starts the Lifting Station pump after a time interval of 48/72 hours (the designated emptying time). If a new precipitation event begins during this interval, the sensor resets the waiting time.

Once the basin is emptied, the level switch deactivates the pump, and the system returns to standby mode.

Wastewater and leachate treatment plants for ecological collection centers

Careful attention must be paid to the design of ecological collection centers where plant clippings/pruning waste, paper, leachate, etc., are present, as these can cause issues for the systems.

First-flush rainwater treatment in ecological centers must include storage tanks, oil removal, lamella pack coalescence filtration, and a first-flush kit with PLC, rain sensors, and a GSM telephone dialer. The sizing of the systems will depend on the surface area, the type of wastewater to be treated, and the final discharge destination (public sewer or surface waters). Over the years, Edil Impianti2 has built numerous first-flush systems for ecological centers and biogas plants, and provides maintenance through its own specialized staff. First-flush rainwater treatment systems for areas used for waste storage and municipal solid waste collection centers with plant clipping storage (Typical plant: screen, storm overflow/diverter manhole, first-flush tank, oil separator). In the construction of biogas plants, it is necessary to adapt the purification systems and first-flush systems. Regulations require the treatment of first-flush rainwater and washing water from the external areas of biogas plants.

Operation and Maintenance

More and more frequently, systems of this type are built and connected with very little attention from the client or end user. This leads to management-related issues within a short time, often resulting in administrative fines, discharge blockages, criminal charges, etc. Edil Impianti's advice is to perform and schedule the following operations for every installed system: commissioning at the end of works with the issuance of a certificate; routine maintenance (appointment of an internal maintenance manager) and the creation of a maintenance log; extraordinary maintenance (contract with the manufacturer or a specialized company); procurement of ready-to-use spare parts and filters for immediate replacement; and a contract with a vacuum truck company for periodic or emergency cleaning.

In-depth analysis of sizing for the Lombardy Region

(Regulation for the disposal of first-flush rainwater and washing water from external areas Regional Regulation March 24, 2006, No. 4, Regional Law No. 26 of December 12, 2003);

«storm event» means one or more atmospheric precipitations, even if temporally separated, with a total depth of at least 5 mm, occurring at an interval of at least 96 hours from a similar previous event; «first-flush water» means the water corresponding, in the first part of each storm event, to a precipitation of 5 mm uniformly distributed over the entire drainage surface served by the rainwater collection network. First-flush water and washing water, to be discharged into a surface water body, onto the soil, or into the superficial layers of the subsoil, must be directed to specific perfectly watertight collection tanks, sized to hold a total of no less than 50 m³ per hectare of drainage surface (hereinafter referred to as first-flush tanks). A specific collection and conveyance network must be designated for rainwater runoff, equipped, in the cases referred to in paragraph 2, with a feeding system for the first-flush tanks that automatically excludes them once filling is complete; the network must be sized based on short-duration, high-intensity storm events characteristic of each area, and in any case, assuming that the event occurs within fifteen minutes and that the runoff coefficient to the network is equal to 1 for the drainage surface and 0.3 for any contiguous permeable surfaces, excluding uncultivated and agricultural surfaces from the calculation. Rainwater runoff from surfaces contaminated by mineral hydrocarbons, as an alternative to the separation of first-flush water referred to in paragraph 2, may undergo treatment in continuous flow systems, designed based on the maximum flow rate estimated in connection with the storm events referred to in paragraph 3, without prejudice to compliance with the emission limit values referred to in Article 7, paragraph 1.

In-depth analysis of sizing for the Veneto Region

For the purpose of calculating the volumes to be pre-treated or sent for purification (in the areas of Belluno, Padua, Treviso, Rovigo, Verona, Venice, Vicenza), first-flush waters are identified as the water that washes over surfaces during the first 15 minutes of precipitation, which in any case produce a conventional water depth of at least 5 mm uniformly distributed over the entire drainage surface pertaining to the closing section of the relevant elementary catchment area. For flow rate calculation purposes, the conventional runoff coefficients to be assumed are 1 for impermeable surfaces and 0.3 for permeable surfaces, excluding cultivated areas from the calculation. If the reference basin for the calculation—which must coincide with the elementary catchment area actually contributing to the flow rate destined for discharge—has a time of concentration exceeding 15 minutes, the reference time must be equal to:

a) the time of concentration itself, if the portion of the basin with a time of concentration exceeding 15 minutes is greater than 70% of the total basin area;

b) 75% of the time of concentration, and in any case a minimum of 15 minutes, if the portion of the basin with a time of concentration exceeding 15 minutes is less than 30% and more than 15% of the basin area;

c) 50% of the time of concentration, and in any case a minimum of 15 minutes, if the portion of the basin with a time of concentration exceeding 15 minutes is less than 15% of the basin area.

Rainfall events are considered separate if a time interval of at least 48 hours elapses between them.

In-depth Analysis

The pollutant removal capacity during this primary phase is limited to the reduction of suspended solids associated with sedimentation within the basin.

Efficiency can nonetheless be improved by inserting a primary sedimentation stage at the basin or tank inlet to facilitate the accumulation of coarser solids.

These waters, in fact, act as the vehicle through which a significant pollutant load—consisting of a heterogeneous mixture of dissolved, colloidal, and suspended substances, including metals, organic, and inorganic compounds—is discharged into receiving water bodies during rapid transients.

First-flush waters therefore require appropriate treatment to ensure the protection of aquatic ecosystems in accordance with the quality objectives set by European Directives 2000/60/EC (Water Framework Directive) and 91/271/EEC (Concerning urban wastewater treatment).

In urban environments, the sources causing the alteration of rainwater runoff quality can be divided into diffuse sources across the territory (road networks, parking lots, etc.) and point sources such as infrastructural nodes and industrial yards, where the type of pollutant load is strictly linked to the specific activity performed.

Regarding diffuse sources, as documented in literature, numerous monitoring campaigns have been conducted to characterize first-flush waters, aimed at determining both the formation and accumulation process of pollutants and the subsequent transport phase within combined and separate drainage systems.