First Rainwater Tanks for Stormwater Treatment

First Rainwater System in continuous with By-Pass

Sand Trap/Sludge Separator - Oil Separator

compliant with UNI EN 858-1 standard

with Coalescence Filter

Features and operating principle

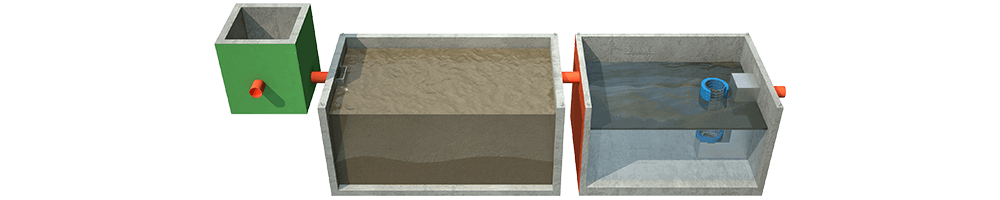

The By-Pass Overflow Chamber is designed to separate the initial runoff (first rainwater), which is contaminated, from the subsequent (second rainwater) flows.

The Sand Trap/Sludge Separator functions to retain sand and other mineral substances that affect wastewater treatment. It is therefore essential in first rainwater treatment systems with continuous or separate storage. Additionally, it is installed for water recovery and reuse in civil and industrial treatment plants, highways, and for lamination and hydraulic invariance treatment.

The Oil Separator with Coalescence Filter and automatic shut-off device specifically functions to naturally separate—without the use of chemical additives—sand, mineral oils, and hydrocarbons present in the incoming wastewater, corresponding to first rainwater or floor wash water. In systems equipped with an Oil Separator, the effluent remains in the main compartment where the flotation of floating substances (oils, hydrocarbons, etc.) occurs. Since these have a lower density than water, they collect on the surface layers, forming an oil layer of increasing thickness based on the incoming concentration of these substances.

Supply specifications

Supply and installation of first rain continuous Sand-Oil Separator with by-pass for the treatment of water from sites with only transit of trucks, produced in DECLARED SERIES, code DD-_____-_S, surface sqm. _____ , total volume before rain mc. __ , diameterDN___ , capacity __ lt./sec., composed of Prefabricated Tanks produced by EDIL IMPIANTI 2 S.r.l. with management system UNI EN ISO 9001 and ISO 45001, made of Solid Concrete Reinforced Vibrato, reinforced with vertical pillars and horizontal struts in stainless steel, with elastomeric protective anti-cracking Elastocolor paint of the external walls in permanent high elasticity and high chemical resistance concrete, concrete in the class of compressive strength C45/55 (RCK >55 N/mm 2), steel internal reinforcement with improved adhesion controlled in the factory and welded mesh type B450C, accompanied by certificates CHEMICAL RESISTANCE and FIRE REACTION (class: A1) issued by external body according to UNI EN standards.

The first continuous rain system Sand-Oil Separator with by-pass is composed of a Sand-Oil Separator in c.a.v. consisting of no._ tank/and cm.___x_____xh____ external dimensions complete with:

-Imprint/holeDN___ in the input;

-Sedimentation and flotation compartment equipped with n._ absorbent cushions for oils and hydrocarbons;

-Internal separation cell in c.a.v.;

-Oil removal compartment withDN___ outlet and coalescence filtration for oils and hydrocarbons (as an alternative to the automatic closing device of the type Float shutter with coalescence filter and removable basket in stainless steel AISI 304 according to UNI EN 858-1).

* External/Internal Scolmatore at the buyer’s expense or on request.

Guarantee of Treatment:

D.Lgs.152/06 Part Three, Annex 5, Table 3 "Discharge into surface waters", provided that the quality and dimensional values of inflow input to the treatment itself are respected and guaranteed, limited to the parameters of total suspended solids and total hydrocarbons.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

Fields of application

Industrial areas, new urban developments, vehicle transit zones, inert material storage, shopping centers, mechanical workshops, body shops, boat storage, ports, freight terminals, roundabouts, roads and highways, general storage facilities. Technology.

First Rainwater System in continuous with By-Pass Dimensions

Download Technical Drawings

Select Article Code to access the Data Sheet for the product.

| Article Code |

Surface (mq) |

Total volume (mc) |

Range (lt/sec) |

Pipes Diam. (mm) |

Desander/Oil Separator | ||||

| External Dimensions (cm) |

Weight (ql) |

Cover slab weight (ql) |

|||||||

| Width | Length | Height | h. 20 cm (D400) |

||||||

| DD-500-1S | 500 | 3,8 | 4,2 | 160 | 175 | 180 | 150 | 26,7 | 15,6 |

| DD-1000-1S | 1.000 | 4,5 | 8,5 | 160 | 180 | 180 | 200 | 53,5 | 16,1 |

| DD-1500-1S | 1.500 | 6,0 | 12,5 | 200 | 180 | 220 | 200 | 60,2 | 19,7 |

| DD-2000-1S | 2.000 | 7,5 | 17,0 | 200 | 180 | 270 | 200 | 68,7 | 24,1 |

| DD-3000-1S | 3.000 | 10,0 | 25,0 | 200 | 246 | 270 | 200 | 88,6 | 33,0 |

| DD-4000-1S | 4000 | 13,0 | 33,5 | 200 | 246 | 320 | 200 | 98,5 | 39,1 |

| DD-5000-1S | 5000 | 21,0 | 42,0 | 200 | 246 | 420 | 250 | 138,0 | 51,3 |

| DD-7000-1S | 7.000 | 24,0 | 58,0 | 200 | 246 | 470 | 250 | 154,6 | 57,4 |

| DD-8000-1S | 8.000 | 30,0 | 67,0 | 200 | 246 | 570 | 250 | 177,0 | 69,7 |

| DD-10000-1S | 10.000 | 32,0 | 84,0 | 250 | 246 | 620 | 250 | 188,2 | 75,8 * |

| DD-12500-1S | 12.500 | 40,0 | 105,0 | 250 | 246 | 770 | 250 | 227,1 | 94,1 * |

| DD-15000-2S | 15.000 | 52,0 | 125,0 | 250 | 246 | 2x 520 | 250 | 152,7 + 165,8 | 2x 63,6 |

| DD-18000-2S | 18.000 | 64,0 | 150,0 | 250 | 246 | 2x 620 | 250 | 175,1 + 188,2 | 2x 75,8 * |

| DD-20000-2S | 20.000 | 70,0 | 167,0 | 250 | 246 | 2x 670 | 250 | 186,2 + 199,3 | 2x 81,9 * |

| DD-23000-2S | 23000 | 80,0 | 192,0 | 250 | 246 | 2x 770 | 250 | 214,0 + 227,1 | 2x 94,1 * |

| DD-25000-2S | 25.000 | 84,0 | 209,0 | 250 | 246 | 2x 820 | 250 | 225,2 + 238,3 | 2x 100,2 * |

| DD-30000-3S | 30.000 | 111,0 | 250,0 | 250 | 246 | 3x 720 | 250 | 2x 202,8 + 215,9 | 3x 88,0 * |

* Cover Slab divided into two parts - The data reported is purely indicative

It is possible to have extensions (bottomless tanks) for all of our products

For Dimensioning with bigger volumes other than those reported in the table, please contact our Technical Department.