First Rainwater Tanks for Stormwater Treatment

First rainwater treatment with internal oil skimmer separator

Compact model

Internal Oil Separator compliant with UNI EN 858-1 Standard

Automatic shut-off device of the float-shutter type

Introduction

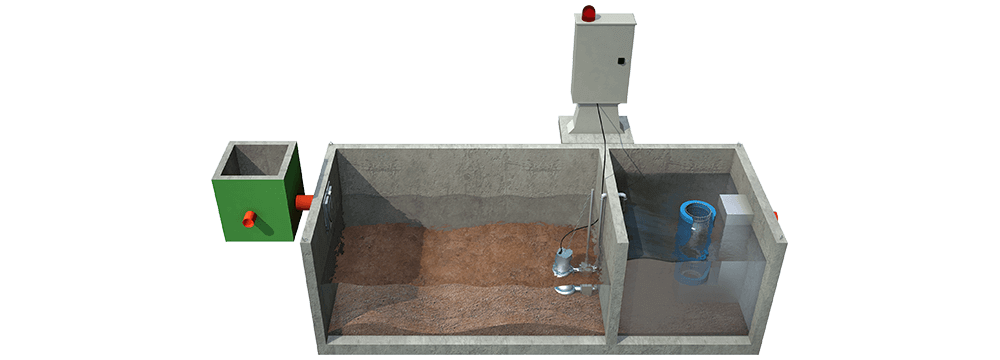

Monoblock concrete first flush rainwater systems with internal oil/liquid separator represent the ideal solution for the treatment of runoff rainwater from impermeable surfaces such as industrial yards, parking lots, service areas, and goods handling zones. These systems meet the needs of those seeking prefabricated reinforced concrete first flush tanks, ensuring maximum efficiency in the separation of pollutants (oils, hydrocarbons, suspended solids) and full compliance with current regulations (Italian Legislative Decree 152/2006, UNI EN 858). The integration of the internal oil separator allows for a complete, pre-assembled system, reducing installation time and costs and simplifying the management of hydraulic connections on site.

Features and Operating Principles

The first flush rainwater system with internal oil separator has the same function as traditional first flush systems but represents an advantageous solution as it allows the client/installer to save time and costs on the hydraulic connections to be carried out on site while ensuring compliance with all technical requirements and reference standards.

The main advantage is therefore having a complete system fully pre-assembled within the same manufactured unit.

Structure and Materials

- Vibrated reinforced concrete monoblock: manufactured in the factory, it guarantees total impermeability, mechanical resistance, and long life even when exposed to aggressive chemical substances.

- Pre-fabricated: the monolithic solution eliminates the risk of infiltration between joints and ensures quick and safe installation.

- Vehicle or pedestrian cover: designed to withstand high loads, ideal for installation even beneath trafficked areas.

Components

- Accumulation tank: sized according to the draining surface area and current regulations, it retains the first flush volume for the time necessary for pollutant sedimentation.

- Internal oil separator with coalescence system: integrated within the manufactured unit, it allows for the separation of oils and hydrocarbons according to UNI EN 858-1 and 858-2 standards.

- Sand separation system: promotes the sedimentation of coarse solid materials.

- Electrical control panel: manages the automatic emptying cycle and level control.

- Lift pump: activated automatically after every rain event to empty the tank within the time limits set by regulations (48/96 hours).

Operation Steps

1) The first flush rainwater is conveyed into the monoblock tank via the overflow manhole.

2) Inside the tank, sand separation and oil separation occur via the internal oil separator with an integrated coalescence system.

3) Once the maximum level is reached, the subsequent rainwater (second flush) is bypassed directly to the discharge.

4) At the end of the rain event, the lift pump empties the tank, allowing the system to be reused for subsequent precipitation.

Supply Specifications

Supply and installation of a First Rainwater Treatment with Internal Oil Skimmer Separator in discontinuous mode mod. RAINDIS_ _____________ Useful Volume F.F. + Oil Separator __,_ cu.m.

Sizing:

- ITALY NATIONAL REFERENCE D.Lgs.152/06 (5 mm/sq.m) up to areas of sq.m _____;

- Region EMILIA ROMAGNA D.G.R.286/05 and 1860/06

Cf*=100 (reduced) up to areas of sq.m ____

Cf*=200 (medium) up to areas of sq.m ____

Cf*=300 (high) up to areas of sq.m ____;

- Region ABRUZZO L.R.31/10 (4 mm/sq.m) up to areas of sq.m _____.

The system consists of:

- n._ First Flush Tank/Tanks mod.VACM__________ dimensions ___x___xh___ cm (excluding cover);

- Clapet check valve at the inlet DN___ mod.VALVCLAPETDN___ made of AISI 304 stainless steel installed in the tank (alternatively, Float check valve DN___ mod.VALVGALINOX___ made of AISI 304 stainless steel);

- Integrated automatic first flush water disposal system cod.KITPP1P complete with n.1 Submersible electric pump mod.GQS50-8 400V 0.55W 1.6A with relative PVC piping, Electrical control and management panel with programmable PLC logic directly from the annexed touchscreen display, Level sensors installed in the tank, External rain sensor and Optical/acoustic alarm;

- Internal reinforced concrete baffle for the formation of the oil separation compartment;

- Internal Static Oil Separator Class I conforming to UNI EN 858, NS ___ lt/sec, complete with automatic shut-off device with float stopper and removable coalescing filter in polyester-based expanded polyurethane with a defined and uniform pore structure, with porosity 10 ppi (pores/inch), complete with removable basket, all made of AISI 304 stainless steel.

Prefabricated specifications:

- Product in DECLARED SERIES and with UNI EN ISO 9001 and ISO 45001 management system;

- Compression resistance class C45/55 (RCK >55 N/mm²);

- Exposure classes XC4, XS3-XD3, XF1, XA2;

- GREESMIX5® steel fibers (if structurally required);

- IDROCONCRETE 1200® integral system (if requested);

- Certificate of conformity for Prefabricated elements made with CE certified materials and recycled content according to the requirements indicated in the Minimum Environmental Criteria (CAM);

- Chemical Resistance and Reaction to Fire certifications issued by an external body according to UNI EN standards.

Treatment Guarantee:

D.Lgs.152/06 Part three, Annex 5, Table 3 "Discharge into Surface Waters," provided that the qualitative and dimensional values of the inflow entering the treatment itself are respected and guaranteed, limited to the parameters of total suspended solids and total hydrocarbons.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

Main Advantages

- Complete and pre-assembled system: all components are integrated into the same manufactured unit, drastically reducing installation time and hydraulic connection costs on site.

- Simplified maintenance: easy access via inspectable manholes.

- Economic savings: reduced installation time, less labor, and lower site costs.

Main Applications

- Industrial and commercial yards

- Public and private parking lots

- Fuel service stations

- Garages, car washes, wrecking yards

- Logistics and port areas

First rainwater System with internal oil skimmer separator Dimensions

Download Technical Drawings

Select Article Code to access the Data Sheet for the product.

(filter data by Regulation and possibly by Surface Area or Volume)

| Article Code |

Usable Volume F.R. + Oil Skimmer (mc) |

Surface (sqm) | Inlet Pipes Diam. (mm) |

First Rainwater Tank with internal Oil Skimmer | Internal Oil Skimmer NS (lt/sec) |

||||||||

| Italy** (5mm/qm) |

Emilia Romagna (F.R. Vol.+ Sedim.) |

Abruzzo (4mm/qm) |

External Dimensions (cm) |

Weight (ql) |

Cover Slab Weight (ql) |

||||||||

| Sludge Load | Width | Length | Height | h. 20 cm (D400) |

|||||||||

| (a) 100 |

(b) 200 |

(c) 300 |

|||||||||||

| RAINDIS_3,5 | 3,5 | 335 | 295 | 275 | 250 | 420 | 125 | 175 | 180 | 150 | 26,7 | 15,6 | 2 |

| RAINDIS_4,0 | 4,0 | 450 | 400 | 375 | 335 | 565 | 125 | 180 | 220 | 150 | 48,6 | 19,7 | 2 |

| RAINDIS_4,5 | 4,5 | 530 | 450 | 425 | 380 | 660 | 125 | 180 | 240 | 150 | 51,4 | 21,5 | 2 |

| RAINDIS_5,5 | 5,5 | 750 | 665 | 600 | 520 | 935 | 160 | 180 | 300 | 150 | 60,0 | 26,8 | 2 |

| RAINDIS_6,0 | 6,0 | 825 | 740 | 675 | 570 | 1.030 | 160 | 180 | 320 | 150 | 62,9 | 28,6 | 2 |

| RAINDIS_6,5 | 6,5 | 1.015 | 910 | 825 | 705 | 1.270 | 160 | 180 | 370 | 150 | 70,0 | 33,1 | 2 |

| RAINDIS_7,0 | 7,0 | 910 | 815 | 725 | 635 | 1.135 | 160 | 180 | 270 | 200 | 68,7 | 24,1 | 2 |

| RAINDIS_11,5_H200_S10 | 11,5 | 1.680 | 1.500 | 1.350 | 1.165 | 2.100 | 160 | 246 | 320 | 200 | 98,7 | 39,1 | 3 |

| RAINDIS_13,5_H200_S10 | 13,5 | 2.065 | 1.850 | 1.675 | 1.430 | 2.580 | 160 | 246 | 370 | 200 | 108,6 | 45,2 | 3 |

| RAINDIS_17,5_H250_S10 | 17,5 | 2.620 | 2.350 | 2.150 | 1.840 | 3.270 | 200 | 246 | 370 | 250 | 126,5 | 45,2 | 3 |

| RAINDIS_20,0_H250_S10 | 20,0 | 3.110 | 2.790 | 2.525 | 2.160 | 3.885 | 200 | 246 | 420 | 250 | 144,2 | 51,3 | 3 |

| RAINDIS_22,0_H250_S10 | 22,0 | 3.560 | 3.195 | 2.900 | 2.480 | 4.450 | 200 | 246 | 470 | 250 | 155,4 | 57,4 | 3 |

| RAINDIS_24,5_H250_S10 | 24,5 | 4.050 | 3.640 | 3.300 | 2.825 | 5.065 | 200 | 246 | 520 | 250 | 166,5 | 63,6 | 3 |

| RAINDIS_27,0_H250_S10 | 27,0 | 4.545 | 4.085 | 3.700 | 3.165 | 5.680 | 200 | 246 | 570 | 250 | 177,6 | 69,7 | 3 |

| RAINDIS_29,5_H250_S10 | 29,5 | 5.035 | 4.525 | 4.100 | 3.520 | 6.295 | 200 | 246 | 620 | 250 | 188,8 | 75,8* | 3 |

| RAINDIS_32,0_H250_S10 | 32,0 | 5.525 | 4.965 | 4.500 | 3.860 | 6.910 | 200 | 246 | 670 | 250 | 206,5 | 81,9* | 3 |

| RAINDIS_34,0_H250_S10 | 34,0 | 5.980 | 5.365 | 4.875 | 4.170 | 7.475 | 200 | 246 | 720 | 250 | 217,6 | 88,0* | 3 |

| RAINDIS_36,5_H250_S10 | 36,5 | 6.470 | 5.815 | 5.275 | 4.500 | 8.090 | 200 | 246 | 770 | 250 | 228,8 | 94,1* | 3 |

| RAINDIS_39,0_H250_S10 | 39,0 | 6.960 | 6.255 | 5.675 | 4.855 | 8.700 | 200 | 246 | 820 | 250 | 239,9 | 100,2* | 3 |

| RAINDIS_41,5_H250_S10 | 41,5 | 7.455 | 6.700 | 6.075 | 5.195 | 9.315 | 200 | 246 | 870 | 250 | 251,1 | 106,3* | 4-8 |

| RAINDIS_44,0_H250_S10 | 44,0 | 7.945 | 7.140 | 6.475 | 5.520 | 9.930 | 200 | 246 | 920 | 250 | 268,8 | 112,4* | 4-8 |

| RAINDIS_46,0_H250_S10 | 46,0 | 8.395 | 7.545 | 6.850 | 5.860 | 10.495 | 200 | 246 | 970 | 250 | 279,9 | 118,5* | 4-8 |

| RAINDIS_48,5_H250_S10 | 48,5 | 8.905 | 8.000 | 7.250 | 6.195 | 11.130 | 200 | 246 | 1020 | 250 | 291,0 | 124,7* | 4-8 |

| RAINDIS_50,5_H270_S10 | 50,5 | 9.195 | 8.265 | 7.500 | 6.415 | 11.490 | 200 | 246 | 970 | 270 | 294,1 | 118,5* | 4-8 |

| RAINDIS_53,0_H270_S10 | 53,0 | 9.745 | 8.760 | 7.950 | 6.790 | 12.180 | 200 | 2x246 | 520 | 270 | 161,1 + 175,4 | 2x63,6 | 4-8 |

| RAINDIS_53,5_H250_S10 | 53,5 | 9.885 | 8.885 | 8.075 | 6.905 | 12.355 | 200 | 2x246 | 570 | 250 | 164,5 + 177,6 | 2x69,7 | 4-8 |

| RAINDIS_57,5_H250_S10 | 57,5 | 10.605 | 9.530 | 8.650 | 7.390 | 13.255 | 300 | 2x246 | 620 | 250 | 175,7 + 188,8 | 2x75,8* | 4-8 |

| RAINDIS_57,5_H270_S10 | 57,5 | 10.575 | 9.505 | 8.625 | 7.360 | 13.215 | 300 | 2x246 | 570 | 270 | 172,7 + 187,0 | 2x69,7 | 4-8 |

* Cover Slab divided into two parts

** Puglia Region: Grating system required upstream of the plant

The data reported is purely indicative

It is possible to have extensions (bottomless tanks) for all of our products

For Dimensioning with bigger volumes other than those reported in the table, please contact our Technical Department.

Emilia Romagna Regulation Reference

| Type of Operation | Coefficient Cf | |

| (a) Reduced | All rainwater collection areas where small quantities of silt produced by traffic or similar are present, namely collection basins in fuel storage areas and covered filling stations. | 100 |

| (b) Medium | Filling stations, manual car washes, component washing, bus wash areas. | 200 |

| (c) High | Washing facilities for construction vehicles, construction machinery, truck wash areas, self-service car washes. | 300 |