SBR Wastewater Treatment System from 5 to 50 Population Equivalent (P.E.)

From 60 P.E. up to 300 P.E., please contact our Technical Office

Features

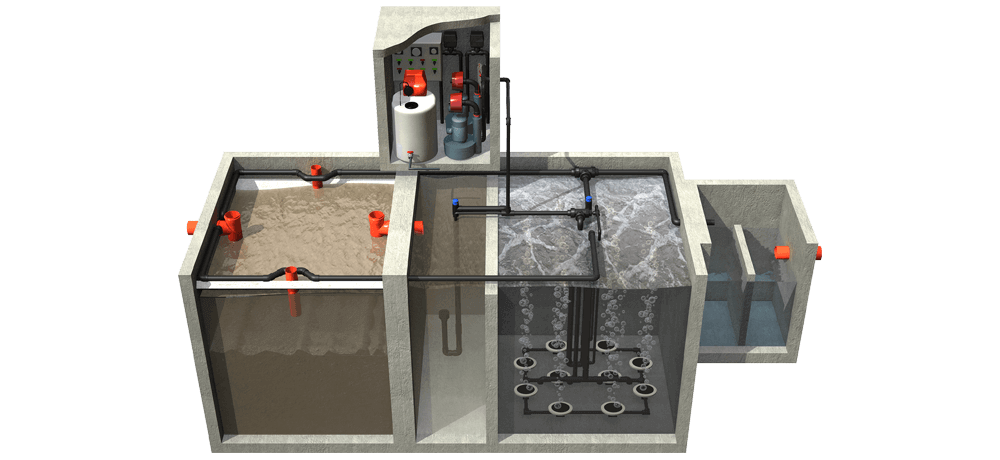

SBR (Sequencing Batch Reactors) Wastewater Treatment Plants are discontinuous flow biological treatment systems. They consist of a tank where biological oxidation and sedimentation processes take place, and from which both the treated effluent and excess sludge are extracted.

These processes are carried out at different times by cyclically varying the plant's operating conditions. By appropriately managing the timing of the various phases, an activated sludge process is essentially reproduced; however, the different process phases follow a temporal rather than spatial sequence as in traditional plants.

The incoming sewage enters the reactor during the filling phase.

The sewage components are not degraded during the static filling phase.

Aerobic reactions begin during aerated filling, while anoxic and anaerobic reactions occur during mixed filling.

In general, the duration of these phases depends on the mass flow rate, the readily biodegradable substrate, and the feeding strategy.

Reactions initiated during filling are completed during the mixed and aerated reaction phases.

The sedimentation, discharge, and idle phases complete the cycle.

In an SBR plant, eight different process phases can be distinguished, occurring in temporal sequence:

Static fill; mixed fill; aerated fill; mixed reaction; aerated reaction; sedimentation; discharge; and idle.

Some phases are always present, such as sedimentation and extraction, while other filling and reaction phases may be only partially present; in some cases, one phase may exclude another.

As previously mentioned, the various phases hypothesized here, along with their relative durations, can be conveniently modified according to specific needs without particular issues, thanks to the maximum flexibility that characterizes the system.

The control of the entire system is achieved through level sensors and actuators connected to a microprocessor, which also manages the feed pumps, sludge wasting pumps, and any discharge pump.

Advantages of SBR Systems

SBR systems have found wide application, especially abroad, for treating wastewater in small communities (particularly coastal ones, where nutrient removal is crucial for eutrophication control) or for industrial wastewater treatment.

In many cases, these systems have been implemented by simply retrofitting traditional activated sludge plants or existing septic tanks.

This application has certainly been favored by the system's structural simplicity and flexibility, allowing for rapid and effective adaptation to diverse conditions.

In summary, the distinctive features of SBR reactors can be summarized as follows:

- High resistance to potential shocks caused by sudden increases in organic load, due to the very nature of these reactors and the presence of an equalization tank upstream;

- Structural simplification, as all different phases of a traditional activated sludge plant, including sedimentation, are combined into a single tank;

- Operational simplicity and process reliability, thanks to automatic control of all pumps (feed, sludge wasting, and effluent/sludge discharge) via a microprocessor and timer system connected to level sensors and/or characteristic physical-chemical parameters;

- Process flexibility, with the ability to easily modify phase durations and achieve high purification efficiency even under non-steady-state conditions. This is particularly relevant for industrial wastewater, characterized by continuous variability in composition.

Particularly important for the achievable purification yield is the ability to vary the duration of the sedimentation phase based on the sludge's settleability characteristics. Moreover, sedimentation occurs under conditions of complete stillness with zero upflow velocity, preventing the formation of preferential paths (short-circuiting), as often happens in continuous-flow sedimentation units.

Furthermore, given the sedimentation surface area, the solids loading per unit area is extremely low, allowing for the removal of even the most difficult-to-settle particles.

Operating flexibility should also be highlighted for the reaction phase, which can be modified by simply varying durations and operating modes.

It can be conducted in environments with different characteristics, allowing for the removal of: organic matter alone, nitrogen (nitrification/denitrification), and phosphorus.

This enables optimal management of the "resources" used in purification, following a logic inspired by sustainable pollutant control criteria.

- Absence of recirculation (both for sludge and aerated mixture): this feature allows for highly effective use of organic matter for denitrification, which is decisive for wastewater with low COD/N ratios.

Additionally, the absence of recirculation pumps provides a clear economic advantage.

- Higher oxygen transfer efficiency in the tank during the aeration phase, since dissolved oxygen concentrations decrease to near-zero values during the feed and reaction phases (both anoxic and anaerobic). Numerous authors report transfer efficiencies in the range of 10% to 30%.

- Improved biomass settleability characteristics, due to microbial selection resulting from alternating anoxic, anaerobic, and aerobic phases. While it cannot be stated with absolute certainty that these process conditions always discourage the growth of filamentous bacteria, experimental evidence demonstrates the high settleability and resistance to mechanical shock of activated sludge in SBR systems.

- Greater understanding of ongoing biological processes; indeed, the batch reaction allows for easy determination of pollutant removal kinetics. Furthermore, the batch reaction leverages higher kinetics due to high initial pollutant concentrations (increasing the substrate diffusion rate into the sludge flocs), making SBR systems particularly suitable for treating high-concentration wastewater.

Supply Specifications

Supply and installation of SBR (Sequencing Batch Reactor) Biological Oxidation System produced in DECLARED SERIES code SBR__AE by N.__ A.E., manufactured by EDIL IMPIANTI 2 S.r.l. with a UNI EN ISO 9001 and ISO 45001 management system, made of monobloc Vibrated Reinforced Concrete, reinforced with vertical pillars and horizontal stainless steel struts, with Elastocolor protective anti-cracking elastomeric paint on the external concrete walls for high permanent elasticity and high chemical resistance, concrete in compression strength class C45/55 (RCK >55 N/mm²), internal steel reinforcements with improved adhesion controlled at the factory and B450C type square-mesh electro-welded wire mesh, complete with CHEMICAL RESISTANCE and REACTION TO FIRE (class: A1) certifications issued by an external body according to UNI EN standards.

The SBR Biological Oxidation System is composed of:

1/2/3- Monobloc tank with internal compartments:

- Imhoff Tank compliant with UNI EN 12566-1 and UNI EN 12566-3 standards complete with inlet and outlet, annular PVC fittings, AISI 304 or similar stainless steel casing, vents, internal hoppers perfectly sealed for clear separation of the sedimentation/digestion compartments and a separation reinforced concrete partition with the Lifting/Storage compartment;

- Lifting/Storage complete with:

- n.1 reverse air-lift pump supplied complete with liquid suction/delivery pipe, air delivery pipe;

- n.1 electrically actuated valve 12/24/230 V; - SBR Biological Oxidation complete with:

- n.1 reverse air-lift pump supplied complete with liquid suction/delivery pipe and air delivery pipe;

- n.3 electrically actuated valves 12/24/230 V;

- micro-bubble disc diffusers with EPDM membrane complete with perimeter air delivery piping;

- two-stage side-channel blower(s) complete with filter, flexible sleeve, check valve, pipe clamps, AISI 304 stainless steel piping and fittings; - Sewage Disinfection Tank complete with reinforced concrete partition, inlet and outlet, annular PVC fittings, dosing kit composed of: n.1 electronic diaphragm dosing pump, cylindrical self-supporting polyethylene tank and suction system on a rod complete with terminal filter;

- Technical Compartment made with a reinforced concrete block complete with an AISI 304 stainless steel door with standard lock and n.1 electrical panel/touch screen control unit with PLC logic for controlling the various utilities.

Treatment Guarantee:

Legislative Decree 152/06 Part three, Annex 5, Table 3 "Discharge into Surface Waters", provided that the qualitative and dimensional values of the incoming flow to the treatment are respected and guaranteed.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

SBR System (Sequencing Batch Reactor) Dimensions

Download Technical Drawings

Select Article Code to access the Data Sheet for the product.

| Article Code |

P. E. Number |

Water supply Lt/AE/g |

Hydraulic Flow Rate daily Qg (mc/day) |

Daily Organic Load Kg BOD5/g |

Monoblock ** | Final Disinfection (cm.) | Technical Compartment (cm.) | |||||||

| External Dimensions (cm) |

Weight (ql) |

Cover slab weight (ql) | External Dimensions (cm) |

Weight (ql) |

Cover slab weight (ql) | External Dimensions (cm) |

Weight (ql) |

|||||||

| h. 15 cm (C250) |

h. 20 cm (D400) |

h. 15 cm (C250) |

h. 20 cm (D400) |

|||||||||||

| SBR10AE | 10 | 200 | 1,0 | 0,3 | 180x270xH200 | 78,6 | 18,1 | 24,1 | 125x130xH200 | 33,1 | 6,1 | 8,1 | 125x110xH130 | 12,0 |

| SBR15AE | 15 | 200 | 3,0 | 0,9 | 180x320xH200 | 87,0 | 21,5 | 28,6 | 125x130xH200 | 33,1 | 6,1 | 8,1 | 125x110xH130 | 12,0 |

| SBR20AE | 20 | 200 | 4,0 | 1,2 | 246x320xH200 | 110,7 | 29,3 | 39,1 | 125x130xH200 | 33,1 | 6,1 | 8,1 | 125x110xH130 | 12,0 |

| SBR25AE | 25 | 200 | 5,0 | 1,5 | 246x370xH200 | 121,2 | 33,9 | 45,2 | 125x130xH200 | 33,1 | 6,1 | 8,1 | 125x110xH130 | 12,0 |

| SBR35AE | 35 | 200 | 7,0 | 2,1 | 246x470xH200 | 145,6 | 43,1 | 57,4 | 125x130xH200 | 33,1 | 6,1 | 8,1 | 125x110xH130 | 12,0 |

| SBR50AE | 50 | 200 | 10,0 | 3,0 | 246x270xH200+ 246x320xH200 |

92,8+ 88,2 |

24,7+ 29,3 |

33,0+ 39,1 |

125x130xH200 | 33,1 | 6,1 | 8,1 | 125x110xH130 | 12,0 |

** Monoblock: Imhoff Tank-Pumping/Storage-SBR Reactor

The data reported is purely indicative

It is possible to have extensions (bottomless tanks) for all of our products