Civil Wastewater Treatment

Biological Total Oxidation Activated Sludge System

Precast vibrated reinforced concrete monoblock tanks

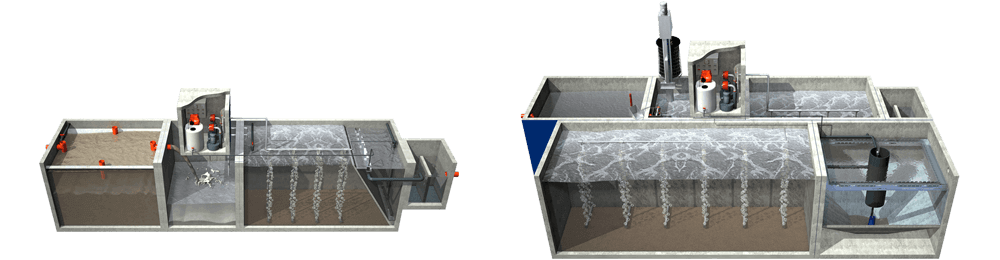

Extended aeration activated sludge biological system for domestic and industrial wastewater. Compact or Modular sizing from 10 to 300 population equivalent

Introduction

The Total Oxidation Activated Sludge Biological System in monobloc reinforced concrete (Compact Tank Model) is a purification system for wastewater treatment, serving isolated houses, small residential areas, tourist activities, restaurants, schools, hospitals, and other activities not served by the public sewer system. The process is based on aerobic biological treatment with suspended biomass through aeration for the formation of active bacterial flora (Activated Sludge) and Final Sedimentation with sludge recirculation.

This system is essentially the artificial application of the natural self-purification process (lakes, watercourses), with the difference that the bacteria in the structure (Oxidation compartment) are found in a higher concentration within a reduced space. The Total Oxidation Activated Sludge Biological System in monobloc reinforced concrete is designed to minimize electricity consumption and maintenance interventions. This type of purifier is highly compact in terms of plant engineering (prefabricated reinforced concrete tanks are used), allowing for a high and constant purification efficiency with maximum operational simplicity. Since the production of excess sludge to be removed is reduced to a minimum, the associated management issues are also minimized. The wide safety margins maintained in the identification of the dimensional parameters allow the purification plant to withstand organic and hydraulic load peaks exceeding 10%, without malfunctions occurring in the biological processes operating within the plant.

In short, the project we propose is characterized by the following aspects:

- Planimetric compactness,

- Ease of management,

- Reduced maintenance and management costs,

- Operational safety and continuity due to the high degree of reliability of the equipment provided,

- Absence of hygienic-environmental inconveniences such as splashing, sewage nebulization, and odors, thanks to the chosen aeration system (fine bubble).

Features and Operating Principle

Imhoff Tank Primary Sedimentation

Upstream of the biological treatment, an IMHOFF-type tank is installed, where primary sedimentation takes place in the upper compartment; this phase is necessary to retain all settleable suspended solids to reduce the organic load entering the biological treatment. Another main function is to retain fine non-biodegradable solids that would clog diffusers, pipes, etc. These could be retained by very fine screens, but that would require daily intervention by management personnel; in this way, intervention will be occasional as it is carried out via vacuum truck service.

Sewage Lifting/Accumulation

The sewage is collected in a suitably sized pit and lifted to the subsequent aeration phase using two submersible pumps (one duty and one standby). The pumps are of the submersible type, electrically connected to level probes for automatic startup. Flow equalization results in a positive indirect effect: a partial homogenization of the concentrations of different pollutants and a consistent homogenization of pollutant loads. The sizing of the equalization tank is determined by the sum of an adequate daily compensation volume, a minimum volume required for the continuous operation of the aeration/mixing equipment for the simultaneous execution of purification processes, and any volume necessary for the equalization of discontinuous loads, taking into account an adequate safety margin.

Sewage Oxidation

This phase is sized so that the sludge loading factor towards the oxidation compartment is appropriate. The tank volume will, in any case, be such as to ensure a suitable retention time, evaluated based on the lifted flow rate. The aeration system is provided with side channel blowers, sufficient to supply the aerated mixture with the correct concentration of dissolved oxygen. The air will be dispersed inside the tank by a series of tubular or disc porous diffusers, arranged along the longitudinal wall.

Tubular air diffusers are particularly suitable for the creation of extractable aeration systems. They essentially consist of a head with a threaded connection, a rigid polypropylene support, and a micro-perforated elastomer tubular membrane, secured with AISI 304 stainless steel clamps.

Disc air diffusers with micro-perforated elastomer membrane for application in wastewater treatment processes in reactors with continuous or intermittent aeration, particularly suitable for the creation of high-efficiency fixed systems.

Final Sedimentation

The sedimentation tank is of the static type (DORTMUND). This phase is sized with particular attention to the upward velocity and the retention time. The tank is complete with a peripheral stainless steel weir launder for the collection of purified water. The hopper walls have a slope greater than 45° to facilitate sludge collection. For lifting the secondary sludge to be sent to the Imhoff tank, a submersible pump is used, which also guarantees continuous sludge recirculation upstream of the biological treatment.

Sewage Disinfection

This is also called "chlorination" because, in most of our purifiers, sodium hypochlorite is used to eliminate the bacterial load present in the wastewater. This phase almost always takes place inside a structure featuring baffles that induce a "back and forth" flow path to decrease the flow rate and increase the contact time with the disinfectant. The system consists of a dosing pump, a storage tank, and a contact tank equipped with baffles to ensure intimate contact between the sewage and the disinfecting agent. The minimum contact time, evaluated on the Qeq, is about 30 minutes (sufficient time to guarantee good disinfection of the purified sewage). In this phase, the sewage must have a certain clarity and must flow at the right speed to avoid stagnation phenomena; inside the chlorination tank, there must be no surface sludge or persistent foam, except for minimal amounts produced by flow jumps which, in any case, must disappear shortly after.

Imhoff Tank Anaerobic Sludge Digestion

The activated sludge produced by the transformation of organic matter by specific bacteria, separated and collected at the bottom of the sedimentation hoppers, is continuously recycled to the aeration phase, while a part—the waste sludge consisting of the daily excess production—is periodically extracted and sent to the ANAEROBIC DIGESTION compartment of the IMHOFF-type tank; subsequently, the stabilized sludge will be disposed of according to law.

Sizing

To discharge in compliance with the table limits, refer to the system sizing required by Table 3, Annex 5 of Legislative Decree 152/06 for discharge into surface waters.

To size discharge systems in compliance with the table limits required by Table 4, Annex 5 of Legislative Decree 152/06, please contact our Technical Office.

Fields of Application

Civil wastewater applications.

Industrial wastewater applications such as:

- Dairies

- Paper mill effluents

- Medium-load industrial wastewater

- Livestock farms

- Slaughterhouses

- Wineries

- Fruit and vegetable processing industries.

Biological Total Oxidation Activated Sludge System from 10 to 80 P.E.

Supply Specifications

Supply and installation of Total Oxidation Activated Sludge Biological System from 10 to 80 P.E. produced in DECLARE SERIES, code OSBIFA__AE, compact model for N.__ P.E., produced by EDIL IMPIANTI 2 S.r.l. with UNI EN ISO 9001 and ISO 45001 management systems, made of reinforced monobloc vibrated concrete, reinforced with vertical pillars and horizontal stainless steel struts, with Elastocolor protective anti-cracking elastomeric painting of the external concrete walls with high permanent elasticity and high chemical resistance, concrete compressive strength class C45/55 (RCK >55 N/mm²), factory-controlled internal high-bond steel reinforcement and B450C type square mesh electro-welded wire mesh, provided with CHEMICAL RESISTANCE and REACTION TO FIRE certifications (class: A1) issued by an external body according to UNI EN standards.

The compact model Activated Sludge System for N.__ P.E. consists of a Monobloc tank (1+2+3+4) containing the following compartments:

- Imhoff Tank (primary sedimentation - anaerobic digestion) compliant with UNI EN 12566-1 and UNI EN 12566-3 standards, complete with inlet/outlet, corrugated PVC fittings, AISI 304 stainless steel or similar casing, vents, and perfectly sealed internal hoppers for the clear separation of the sedimentation compartments;

- Lifting/Accumulation complete with inlet, corrugated PVC fittings, n.1 submersible electric pump Calpeda brand or similar (having the following minimum technical characteristics: 2-pole induction motor, 50 Hz, 230/400 V power supply, class F insulation, IP X8 protection, 0.55 kW power, 2.6/1.5 A absorption, Q= 12 m³/h - H= 6 m, vortex back-impeller), PVC delivery piping, special fittings, regulation valves, and a telescopic system for regulating the feed flow to the oxidation compartment made of AISI 304 stainless steel;

- Oxidation (aerobic biological treatment) complete with inlet and outlet, any corrugated PVC fittings, porous micro-bubble diffusers with EPDM membrane, downpipes and air distribution manifold made of AISI 304 stainless steel complete with flow regulation valve on each single downpipe, n.1+1 side channel blower FPZ brand or similar with technical characteristics as per the technical report;

- Final Sedimentation (with sludge recirculation) complete with n.1 air-lift pump for sludge recirculation made of PVC, complete with special fittings, fixing brackets and AISI 304 stainless steel hardware, Thomson type weir launder complete with adjustment and support brackets entirely made of PVC;

- Final Disinfection Tank made of a reinforced concrete structure complete with reinforced concrete baffles, inlet/outlet, corrugated PVC fittings, dosing kit consisting of: n.1 electronic diaphragm dosing pump Doseuro brand or similar with technical characteristics as per the technical report, complete with suction system on rod with terminal filter;

- Technical Room made of a reinforced concrete structure complete with an AISI 304 stainless steel front door with standard lock, complete with grilles to ensure the minimum essential internal ventilation for the correct operation of the blower, n.1 electrical panel with programmable PLC logic for the control of the various units.

Treatment Guarantee:

Legislative Decree 152/06 Part Three, Annex 5, Table 3 "Discharge into Surface Waters", provided that the qualitative and dimensional values of the inflow to the treatment itself are respected and guaranteed.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

Biological Total Oxidation Activated Sludge System from 10 to 80 P.E. Dimensions

Download Technical Drawings

Select Article Code to access the Data Sheet for the product.

Plant Dimensional Characteristics

| Article Code |

Number P.E. |

Water supply Lt/AE/g |

Hydraulic Flow Rate daily Qg (mc/day) |

Peak Hydraulic Flow Qp mc/h |

Procapite Organic Load BOD5 gr/PE/d |

Daily Organic Load Kg BOD5/g |

Sludge Load Cf (Kg BOD5/ Kg. SS x d) |

Volume Load Cv (Kg BOD5/mc x d) |

Biological Sludge Concentration (Kg SS/mc) |

| OSBIFA10AE | 10 | 200 | 2,0 | 0,2 | 60,0 | 0,6 | 0,08 | 0,30 | 4,0 |

| OSBIFA25AE | 25 | 200 | 5,0 | 0,5 | 60,0 | 1,5 | 0,08 | 0,30 | 4,0 |

| OSBIFA35AE | 35 | 200 | 7,0 | 0,7 | 60,0 | 2,1 | 0,08 | 0,30 | 4,0 |

| OSBIFA50AE | 50 | 200 | 10,0 | 1,0 | 60,0 | 3,0 | 0,08 | 0,30 | 4,0 |

| OSBIFA80AE | 80 | 200 | 16,0 | 1,6 | 60,0 | 4,8 | 0,08 | 0,30 | 4,0 |

Sizing

| Article Code |

Monoblock ** | Final Disinfection | Technical Compartment | |||||

| External Dimensions (cm) |

Weight (ql) | Weight of Cover Slab (ql) |

External Dimensions (cm) |

Weight (ql) | Weight of Cover Slab (ql) |

External Dimensions (cm) |

Weight (ql) | |

| h. 20 cm (D400) |

h. 20 cm (D400) |

|||||||

| OSBIFA10AE | 180x370xH200 | 101,9 | 33,1 | 125x130xH200 | 30,9 | 8,1 | 125x110xH130 | 12,0 |

| OSBIFA25AE | 180x420xH200 | 110,6 | 37,6 | 125x130xH200 | 30,9 | 8,1 | 125x110xH130 | 12,0 |

| OSBIFA35AE | 246x470xH250 | 184,2 | 57,4 | 125x130xH250 | 37,3 | 8,1 | 125x110xH130 | 12,0 |

| OSBIFA50AE | 246x520xH250 | 196,5 | 63,6 | 125x130xH250 | 37,3 | 8,1 | 125x110xH130 | 12,0 |

| OSBIFA80AE | 246x570xH250 | 207,9 | 69,7 | 125x130xH250 | 37,3 | 8,1 | 125x110xH130 | 12,0 |

** Monobloc: Imhoff tank-Lifting/Storage-Oxidation-Final Sedimentation

The data reported is purely indicative

It is possible to have extensions (bottomless tanks) for all of our products

Biological Total Oxidation Activated Sludge System from 100 to 200 P.E.

Supply Specifications

Supply and installation of Total Oxidation Activated Sludge Biological System from 100 to 200 P.E. produced in DECLARE SERIES, code OSBIFA___AE, modular from N.___ P.E., consisting of Prefabricated Underground Tanks produced by EDIL IMPIANTI 2 S.r.l. with UNI EN ISO 9001 and ISO 45001 management systems, made of reinforced monobloc vibrated concrete, reinforced with vertical pillars and horizontal stainless steel struts, with Elastocolor protective anti-cracking elastomeric painting of the external concrete walls with high permanent elasticity and high chemical resistance, concrete compressive strength class C45/55 (RCK >55 N/mm²), factory-controlled internal high-bond steel reinforcement and B450C type square mesh electro-welded wire mesh, provided with CHEMICAL RESISTANCE and REACTION TO FIRE certifications (class: A1) issued by an external body according to UNI EN standards.

The modular Activated Sludge System for N.___ P.E. consists of:

- Imhoff Tank (primary sedimentation - anaerobic digestion) compliant with UNI EN 12566-1 and UNI EN 12566-3 standards, complete with inlet/outlet, corrugated PVC fittings, AISI 304 stainless steel or similar casing, vents, perfectly sealed internal hoppers for the clear separation of the sedimentation/digestion compartments, sludge discharge pipe complete with 63 mm diam. PVC regulation valve, pipe fixing brackets and PVC pipe clamps;

- Lifting/Accumulation Tank complete with inlet, corrugated PVC fittings, n.1 submersible electric pump Calpeda brand or similar (having the following minimum technical characteristics: 2-pole induction motor, 50 Hz, 230/400 V power supply, class F insulation, IP X8 protection, 0.55 kW power, 2.6/1.5 A absorption, Q= 12 m³/h - H= 6 m, vortex back-impeller), PVC delivery piping, special fittings, regulation valves, telescopic system for regulating the feed flow to the oxidation compartment made of AISI 304 stainless steel; followed by (3+4) Monobloc tank containing the following compartments:

- Oxidation (aerobic biological treatment) complete with inlet/outlet, any corrugated PVC fittings, porous micro-bubble diffusers with EPDM membrane, downpipes and air distribution manifold made of AISI 304 stainless steel complete with flow regulation valve on each single downpipe, n.1+1 side channel blower FPZ brand or similar with technical characteristics as per the technical report;

- Final Sedimentation (with sludge recirculation) complete with n.1 air-lift pump for sludge recirculation made of PVC, complete with special fittings, fixing brackets and AISI 304 stainless steel hardware, Thomson type weir launder complete with adjustment and support brackets entirely made of PVC;

- Final Disinfection Tank made of a reinforced concrete structure complete with reinforced concrete baffles, inlet/outlet, corrugated PVC fittings, dosing kit consisting of: n.1 electronic diaphragm dosing pump Doseuro brand or similar with technical characteristics as per the technical report and adjustment to the general electrical panel for the dosing pump control with adjustable daily timed ignition, complete with suction system on rod with terminal filter;

- Technical Room made of a reinforced concrete structure complete with an AISI 304 stainless steel front door with standard lock, complete with grilles to ensure the minimum essential internal ventilation for the correct operation of the blower, n.1 electrical panel with programmable PLC logic for the control of the various units.

Treatment Guarantee:

Legislative Decree 152/06 Part Three, Annex 5, Table 3 "Discharge into Surface Waters", provided that the qualitative and dimensional values of the inflow to the treatment itself are respected and guaranteed.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

Biological Total Oxidation Activated Sludge System from 100 to 200 P.E. Dimensions

Download Technical Drawings

Select Article Code to access the Data Sheet for the product.

Plant Dimensional Characteristics

| Article Code |

Number P.E. |

Water supply Lt/AE/g |

Hydraulic Flow Rate daily Qg (mc/day) |

Peak Hydraulic Flow Qp mc/h |

Procapite Organic Load BOD5 gr/PE/d |

Daily Organic Load Kg BOD5/g |

Sludge Load Cf (Kg BOD5/ Kg. SS x d) |

Volume Load Cv (Kg BOD5/mc x d) |

Biological Sludge Concentration (Kg SS/mc) |

| OSBIFA100AE | 100 | 200 | 20,0 | 1,70 | 60,0 | 6,0 | 0,08 | 0,32 | 4,50 |

| OSBIFA150AE | 150 | 200 | 30,0 | 2,50 | 60,0 | 9,0 | 0,08 | 0,32 | 4,50 |

| OSBIFA200AE | 200 | 200 | 40,0 | 3,30 | 60,0 | 12,0 | 0,08 | 0,32 | 4,50 |

Sizing

| Article Code |

Imhoff Tank | Pumping/Storage | Monoblock ** | Final Disinfection | Technical Compartment | |||||||||

| External Dimensions (cm) |

Weight (ql) | Weight of Cover Slab (ql) |

External Dimensions (cm) |

Weight (ql) | Weight of Cover Slab (ql) |

External Dimensions (cm) |

Weight (ql) | Weight of Cover Slab (ql) |

External Dimensions (cm) |

Weight (ql) | Weight of Cover Slab (ql) |

External Dimensions (cm) |

Weight (ql) | |

| h. 20 cm (D400) |

h. 20 cm (D400) |

h. 20 cm (D400) |

h. 20 cm (D400) |

|||||||||||

| OSBIFA100AE | 246x470xH250 | 160,2 | 57,4 | 175x180xH250 | 51,4 | 15,6 | 246x420xH250 | 138,4 | 51,3 | 125x130xH250 | 37,3 | 8,1 | 125x110xH130 | 12,0 |

| OSBIFA150AE | 246x620xH250 | 200,0 | 75,8 * | 175x180xH250 | 51,4 | 15,6 | 246x570xH250 | 177,9 | 69,7 | 125x130xH250 | 37,3 | 8,1 | 125x110xH130 | 12,0 |

| OSBIFA200AE | 246x670xH250 | 213,2 | 81,9 * | 246x220xH250 | 80,2 | 26,9 | 246x670xH250 | 200,5 | 81,9 * | 125x130xH250 | 37,3 | 8,1 | 125x110xH130 | 12,0 |

** Monobloc: Oxidation/Final Sedimentation

* Cover Slab divided into two parts - The data reported is purely indicative

It is possible to have extensions (bottomless tanks) for all of our products

Biological Total Oxidation Activated Sludge System from 250 to 300 P.E.

Supply Specifications

Supply and installation of Total Oxidation Activated Sludge Biological System from 250 to 300 P.E. produced in DECLARE SERIES, code OSBIFA___AE, modular from N.___ P.E., consisting of Prefabricated Underground Tanks produced by EDIL IMPIANTI 2 S.r.l. with UNI EN ISO 9001 and ISO 45001 management systems, made of reinforced monobloc vibrated concrete, reinforced with vertical pillars and horizontal stainless steel struts, with Elastocolor protective anti-cracking elastomeric painting of the external concrete walls with high permanent elasticity and high chemical resistance, concrete compressive strength class C45/55 (RCK >55 N/mm²), factory-controlled internal high-bond steel reinforcement and B450C type square mesh electro-welded wire mesh, provided with CHEMICAL RESISTANCE and REACTION TO FIRE certifications (class: A1) issued by an external body according to UNI EN standards.

The modular Activated Sludge System for N.___ P.E. consists of:

- Lifting/Accumulation Tank complete with inlet, corrugated PVC fittings; n.1 submersible electric pump Calpeda brand or similar (having the following minimum technical characteristics: 2-pole induction motor, 50 Hz, 230/400 V power supply, class F insulation, IP X8 protection, 0.55 kW power, 2.6/1.5 A absorption, Q= 12 m³/h - H= 6 m, vortex back-impeller), PVC delivery piping, special fittings, regulation valves, telescopic system for regulating the feed flow to the oxidation compartment made of AISI 304 stainless steel; with Vertical Screw Screen for Mechanical Screening made of stainless steel with thick carbon screw, 3 mm hole diameter, 0.75 Kw power, complete with coupling foot and support bracket;

- Wastewater Denitrification Tank complete with n.1 1.10 Kw submerged mixer, complete with stainless steel propeller, AISI 304 stainless steel support and adjustment rod, hot-dip galvanized steel rod fixing bracket for wall mounting, sludge recirculation pipe complete with 63 mm diam. PVC regulation valve, pipe fixing brackets and PVC pipe clamps;

- Total Oxidation Activated Sludge Tank complete with inlet/outlet, any corrugated PVC fittings, porous micro-bubble diffusers with EPDM membrane, downpipes and air distribution manifold made of AISI 304 stainless steel complete with flow regulation valve on each single downpipe, n.1+1 side channel blower FPZ brand or similar with technical characteristics as per the technical report;

- Sludge Sedimentation Tank (Dortmund type) complete with n.1 submersible electric pump Calpeda brand or similar (having the following minimum technical characteristics: 2-pole induction motor, 50 Hz, 230/400 V power supply, class F insulation, IP X8 protection, 0.55 kW power, 2.6/1.5 A absorption, Q= 12 m³/h - H= 6 m, vortex back-impeller), PVC delivery piping, variable rod level detection system, special fittings, regulation valves, PVC deflector cylinder complete with stainless steel support brackets, Thomson type weir launder complete with adjustment and support brackets, entirely made of AISI 304 stainless steel;

- Final Disinfection Tank made of a reinforced concrete structure complete with reinforced concrete baffles, inlet and outlet, corrugated PVC fittings; dosing kit consisting of n.1 electronic diaphragm dosing pump Doseuro brand or similar with technical characteristics as per the technical report, complete with suction system on rod with terminal filter;

- Aerobic Digestion Tank (sludge accumulation) complete with inlet and outlet, any corrugated PVC fittings, 63 mm diam. PN 10 PVC regulation valve, pipe fixing brackets, PVC pipe clamps, porous micro-bubble diffusers with EPDM membrane, downpipes and air distribution manifold made of AISI 304 stainless steel complete with flow regulation valve on each single downpipe;

- Technical Room made of a reinforced concrete structure complete with an EI2 60 type single-leaf front door compliant with UNI EN 1634-1, 90x205 cm, RAL9002 color painting, with standard lock complete with grilles to ensure minimum internal ventilation and n.1 electrical panel with programmable PLC logic for the control of the various units.

Treatment Guarantee:

Legislative Decree 152/06 Part Three, Annex 5, Table 3 "Discharge into Surface Waters", provided that the qualitative and dimensional values of the inflow to the treatment itself are respected and guaranteed.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

Biological Total Oxidation Activated Sludge System from 250 to 300 P.E. Dimensions

Download Technical Drawings

Select Article Code to access the Data Sheet for the product.

Plant Dimensional Characteristics

| Article Code |

Number P.E. |

Water supply Lt/AE/g |

Hydraulic Flow Rate daily Qg (mc/day) |

Peak Hydraulic Flow Qp mc/h |

Procapite Organic Load BOD5 gr/PE/d |

Daily Organic Load Kg BOD5/g |

Sludge Load Cf (Kg BOD5/ Kg. SS x d) |

Volume Load Cv (Kg BOD5/mc x d) |

Biological Sludge Concentration (Kg SS/mc) |

| OSBIFA250AE | 250 | 200 | 50,0 | 4,17 | 60,0 | 15,0 | 0,14 | 0,50 | 4,50 |

| OSBIFA300AE | 300 | 200 | 60,0 | 5,00 | 60,0 | 18,0 | 0,14 | 0,50 | 4,50 |

Sizing

| Article Code |

Pumping/ Storage (tank + cover) |

Wastewater Denitrification (tank + cover) |

Total Oxidation Activated Sludge (tank + cover) |

Sludge Sedimentation (Dortmund) (tank + cover) |

Wastewater Disinfection (tank + cover) |

Aerobic Digestion (tank + cover) |

Technical Compartment |

| OSBIFA250AE | cm. 246x220xH250+20 ql. 80,2 + 26,9 |

cm. 246x270xH250+20 ql. 91,4 + 33,0 |

cm. 246x620xH250+20 ql. 175,1 + 75,8* |

cm. 246x270xH250+20 ql. 102,8 + 33,0 |

cm. 125x180xH250+20 ql. 42,9 + 11,2 |

cm. 246x270xH250+20 ql. 91,4 + 33,0 |

cm. 125x180xH260/265 ql. 51,9 |

| OSBIFA300AE | cm. 246x270xH250+20 ql. 91,4 + 33,0 |

cm. 246x320xH250+20 ql. 102,5 + 39,1 |

cm. 246x670xH250+20 ql. 186,2 + 81,9* |

cm. 246x320xH250+20 ql. 116,1 + 39,1 |

cm. 125x180xH250+20 ql. 42,9 + 11,2 |

cm. 246x370xH250+20 ql. 113,7 + 45,2 |

cm. 125x180xH260/265 ql. 51,9 |

* Cover Slab divided into two parts - The data reported is purely indicative

It is possible to have extensions (bottomless tanks) for all of our products