Civil Wastewater Treatment

Biodisc Biological Waste Water Treatment System

Precast in Reinforced Concrete

from 100 to 200 P.E. and from 250 to 300 P.E.

Introduction

Biological Biodisc Treatment has long been appreciated for the clear advantages this application guarantees, namely:

- rapid process startup;

- silent operation and absence of unpleasant odors;

- low electricity consumption;

- maintenance and assistance reduced to a minimum;

- minimal footprint and therefore low environmental impact.

Biological Biodisc Treatment Plants therefore allow for the biological treatment of domestic and industrial wastewater with high efficiency for both carbon removal (BOD) and nitrification and denitrification processes (nitrogen).

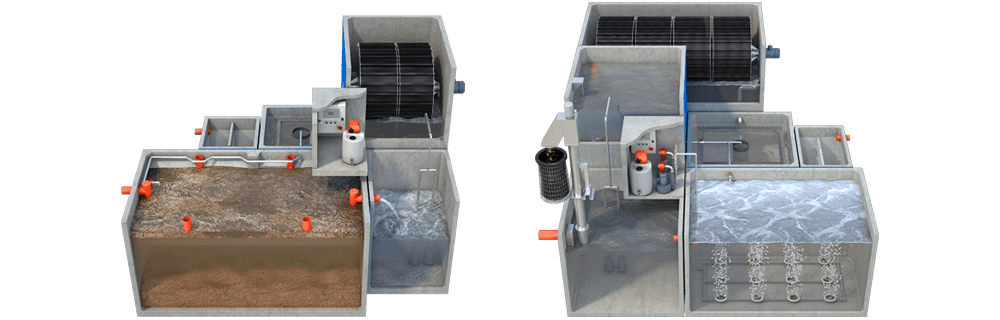

In the Biodisc system, the rotation of the structure allows the biomass and the thin film of sewage adhering to it to come into contact with atmospheric oxygen, enabling its diffusion and utilization. The microorganisms forming the biological flora, placed in direct contact with the two key elements for their development (sewage and air), absorb the greatest amount of organic matter during the immersion phase in the sewage and oxygen during the emersion phase. When the layer of bacterial flora adhering to the discs reaches a thickness of 4/5 mm, it detaches in settleable flocs, which are collected and concentrated in the subsequent final sedimentation phase and from there lifted to the primary digestion phase.

The Biodiscs are housed in Edil Impianti2 prefabricated vibrated reinforced concrete tanks and submerged in the sewage for 40% of their diameter. The Biodisc is made of a series of rollers consisting of a shaft on which a large number of plastic discs are fixed. The shaft is rotated by a gear motor at a speed between 1 and 6 rpm, depending on the diameters and the type of sewage to be treated.

The Biological Biodisc Plant is designed to minimize electricity consumption and maintenance interventions.

Features and Operating Principle

Primary Sedimentation Imhoff Tank

The Imhoff tank is divided into two compartments; the upper compartment is called Primary Sedimentation. This phase is necessary to retain settleable solids to reduce the organic load entering the subsequent biological treatment.

Sewage Lifting/Accumulation

In a suitably sized pit, sewage is collected and sent to biological treatment using submerged pumps. The equalization of the sewage produces the indirect effect of homogenizing the characteristics of the various pollutants.

Biodisc Oxidation

The process is based on aerobic biological treatment with attached biomass, where the Biodisc is used as an inert support on which the bacterial flora develops.

This system is essentially the artificial application of the natural self-purification process (lakes, watercourses), with the difference that the bacteria in the structure (Biodisc Oxidation compartment) are in a higher concentration and in a reduced space.

The support brings the flora itself alternatively into contact with the organic matter contained in the sewage to be treated and with atmospheric oxygen.

The microorganisms forming the biological flora, placed in direct contact with the two key elements for their development and activity, directly absorb the greatest possible amount of organic matter during the immersion phase in the sewage and the proportionally necessary oxygen during the emersion phase.

Final Sedimentation

Final Sedimentation allows for the separation of purified water from the sludge; the surface water flows towards the outlet through a stainless steel peripheral channel with Thompson weirs, while the settled sludge is sent, via a submerged pump, to the head of the Imhoff tank as excess sludge for disposal, following anaerobic digestion.

Secondary or biological sludges are different from primary sludges, which are separated from the raw sewage without undergoing any transformation by bacteria.

Sewage Disinfection

The sewage Disinfection phase takes place in a tank inside which plates are inserted to facilitate a "serpentine path," which in turn causes the slowing down of the sewage and its mixing with sodium hypochlorite.

The time that guarantees good disinfection of the sewage is approximately 30/40 minutes.

Anaerobic Sludge Digestion Imhoff Tank

The produced sludges are conveyed under the hoppers of the Imhoff tank and periodically extracted from the Anaerobic Digestion compartment by tankers, to be subsequently disposed of according to the law.

Sizing

System sizing for discharge in compliance with the threshold limits set by Table 3, Annex 5 of Legislative Decree 152/06 for discharge into surface waters.

For system sizing for discharge in compliance with the threshold limits set by Table 4, Annex 5 of Legislative Decree 152/06, please contact our Technical Office.

Fields of Application

The Biological Biodisc Plant is a purification system for wastewater treatment serving isolated houses, small residential areas, tourist activities, restaurants, schools, hospitals, and other activities not served by the public sewer system.

Civil discharge applications (restaurants, campsites, shopping centers).

Industrial discharge applications such as:

- Wineries

- Paper mill discharges

- Slaughterhouses

- Medium-load industrial wastewater

- Livestock farms

- Breweries

- Wine-producing companies

- Fruit and vegetable processing industries.

Biodisc Biological Waste Water Treatment System from 100 to 200 P.E.

Supply Specifications

Supply and installation of a 100 to 200 P.E. Biodisc Biological Waste Water Treatment System, manufactured in DECLARED SERIES, code BIORUL___PE, modular from N.___ P.E., composed of Pre-fabricated Buried Tanks produced by EDIL IMPIANTI 2 S.r.l. with a UNI EN ISO 9001 and ISO 45001 management system, made of monoblock Vibrated Reinforced Concrete, reinforced with vertical pillars and horizontal tie-rods in stainless steel, with protective anti-cracking elastomeric paint Elastocolor on the external concrete walls for high permanent elasticity and high chemical resistance, concrete in compression strength class C45/55 (RCK >55 N/mm²), internal steel reinforcements with improved adherence controlled in the factory and B450C type square mesh electro-welded wire, complete with CHEMICAL RESISTANCE and REACTION TO FIRE (class: A1) certifications issued by an external body according to UNI EN standards.

The modular N.___ P.E. RBC Plant must be composed of:

- Imhoff Tank (primary sedimentation - anaerobic digestion) compliant with UNI EN 12566-1 and UNI EN 12566-3 standards complete with inlet/outlet, corrugated PVC fittings, AISI 304 stainless steel or similar casing, vents, internal hoppers perfectly sealed for clear separation of sedimentation/digestion compartments, sludge discharge pipe complete with PVC regulation valve diam. 63 mm, pipe fastening brackets and PVC pipe clamps;

- Lifting/Accumulation Tank complete with inlet, corrugated PVC fittings, n.1 submersible electric pump from Calpeda or similar brands (with the following minimum technical characteristics: 2-pole induction motor, 50 Hz, 230/400 V power supply, class F insulation, IP X8 protection, 0.55 kW power, 2.6/1.5 A absorption, Q= 12 mc/h - H= 6 mt, recessed vortex impeller), PVC delivery pipe diam. 63 mm, special fittings, valves for regulating the flow rate to the oxidation compartment, pipe fastening brackets and PVC pipe clamps;

- RBC Oxidation Tank complete with thick steel plates for RBC bearing anchoring, plexiglass windows complete with stainless steel fastening/sliding guides dimensions 60x30 cm, n.2 plexiglass windows complete with stainless steel fastening/sliding guides dimensions 120x60 cm, n.2 PVC gluing sleeves diam. 110, n.1 RBC with a diameter of 195 cm, disc pack length ___ cm, bearing inter-axis length ___ cm, useful surface area ___ sqm, complete with gearmotor Kw.____, with an output speed of 1.7 rpm, n.2 SKF oscillating adapter type ball bearings, n.1 thick central shaft in certified carbon steel ST-52, plates with insertion guides for hot-dip galvanized steel shafts, stainless steel shafts with relative threaded PVC plates, PP AD discs with a diameter of 170 mm;

- Sludge Sedimentation Tank (Dortmund) complete with n.1 submersible electric pump from Calpeda or similar brands (with the following minimum technical characteristics: 2-pole induction motor, 50 Hz, 230/400 V power supply, class F insulation, IP X8 protection, 0.55 kW power, 2.6/1.5 A absorption, Q= 12 mc/h - H= 6 mt, recessed vortex impeller), PVC delivery pipe, special fittings, regulation valves, PVC deflector cylinder diam. 400 complete with stainless steel support brackets, Thomson type weir trough complete with regulation and support brackets, entirely made of AISI 304 stainless steel;

- Wastewater Disinfection Tank made with a reinforced concrete pre-cast structure complete with reinforced concrete partitions, inlet and outlet, corrugated PVC fittings; dosing kit composed of n.1 electronic membrane dosing pump from Doseuro or similar brands with technical characteristics as per the technical report and adaptation to the general electrical panel for controlling the dosing pump with daily adjustable timed start-up, complete with suction system on a rod with a terminal filter;

- Technical Compartment made with a reinforced concrete pre-cast structure complete with a front door made of AISI 304 stainless steel with a standard lock complete with grilles to ensure minimum internal aeration, n.1 electrical panel with programmable PLC logic for controlling the various utilities.

Treatment Guarantee:

Legislative Decree 152/06 Part three, Annex 5, Table 3 "Discharge into Surface Waters", provided that the qualitative and dimensional values of the inflow to the treatment itself are respected and guaranteed.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

Biodisc Biological Waste Water Treatment System from 100 to 200 P.E. Dimensions

Download Technical Drawings

Select Article Code to access the Data Sheet for the product.

Plant Dimensional Characteristics

| Article Code |

Number P.E. |

Water supply Lt/AE/g |

Hydraulic Flow Rate daily Qg (mc/day) |

Peak Hydraulic Flow Qp mc/h |

Procapite Organic Load BOD5 gr/PE/d |

Daily Organic Load Kg BOD5/g |

Usable surface mq | Superficial organic load Co grBOD5/mq/g (approx.) |

| BIORUL100AE | 100 | 200 | 20 | 1,67 | 60 | 6 | 967 | 8 |

| BIORUL150AE | 150 | 200 | 30 | 2,50 | 60 | 9 | 1.106 | 8 |

| BIORUL200AE | 200 | 200 | 40 | 3,33 | 60 | 12 | 1.475 | 8 |

Sizing

| Article Code |

Imhoff Tank (tank + cover) |

Pumping/Storage (tank + cover) |

Biodisc Oxidation (tank + cover) |

Sludge Sedimentation (tank + cover) |

Wastewater Disinfection (tank + cover) |

Technical Compartment |

| BIORUL100AE | cm. 246x470xH250+20 ql. 160,2 + 57,4 |

cm. 175x180xH250+20 ql. 51,4 + 15,6 |

cm. 246x220xH250+10 ql. 80,2 + 13,4 |

cm. 175x180xH250+20 ql. 55,5 + 15,6 |

cm. 125x130xH250+20 ql. 36,0 + 8,1 |

cm. 125x110xH130 ql. 12,0 |

| BIORUL150AE | cm. 246x620xH250+20 ql. 200,0 + 75,8* |

cm. 246x220xH250+20 ql. 80,2 + 26,9 |

cm. 246x270xH250+10 ql. 91,4 + 16,5 |

cm. 246x220xH250+20 ql. 90,1 + 26,9 |

cm. 125x130xH250+20 ql. 37,3 + 8,1 |

cm. 125x110xH130 ql. 12,0 |

| BIORUL200AE | cm. 246x670xH250+20 ql. 213,2 + 81,9* |

cm. 246x220xH250+20 ql. 80,2 + 26,9 |

cm. 246x320xH250+10 ql. 102,5 + 19,6 |

cm. 246x220xH250+20 ql. 90,1 + 26,9 |

cm. 125x130xH250+20 ql. 37,3 + 8,1 |

cm. 125x110xH130 ql. 12,0 |

* Cover Slab divided into two parts - The data reported is purely indicative

It is possible to have extensions (bottomless tanks) for all of our products

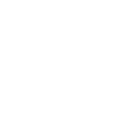

Biodisc Biological Waste Water Treatment System from 250 to 300 P.E.

Supply Specifications

Supply and installation of a 250 to 300 P.E. Biodisc Biological Waste Water Treatment System, manufactured in DECLARED SERIES, code BIORUL___PE, modular from N.___ P.E., composed of Prefabricated Buried Tanks produced by EDIL IMPIANTI 2 S.r.l. with a UNI EN ISO 9001 and ISO 45001 management system, made of monoblock Vibrated Reinforced Concrete, reinforced with vertical pillars and horizontal tie-rods in stainless steel, with protective anti-cracking elastomeric paint Elastocolor on the external concrete walls for high permanent elasticity and high chemical resistance, concrete in compression strength class C45/55 (RCK >55 N/mm²), internal steel reinforcements with improved adherence controlled in the factory and B450C type square mesh electro-welded wire, complete with CHEMICAL RESISTANCE and REACTION TO FIRE (class: A1) certifications issued by an external body according to UNI EN standards.

The modular N.___ P.E. RBC Plant must be composed of:

- Lifting/Accumulation Tank complete with inlet, corrugated PVC fittings; n.1 submersible electric pump from Calpeda or similar brands (with the following minimum technical characteristics: 2-pole induction motor, 50 Hz, 230/400 V power supply, class F insulation, IP X8 protection, 0.55 kW power, 2.6/1.5 A absorption, Q= 12 mc/h - H= 6 mt, recessed vortex impeller), PVC delivery pipe diam. 63 mm, special fittings, valves for regulating the flow rate to the oxidation compartment, pipe fastening brackets and PVC pipe clamps; with a Vertical Screw Screen for Mechanical Screening in stainless steel with a thick carbon screw, 3 mm hole diameter, 0.75 Kw power, complete with coupling foot and support bracket;

- Wastewater Denitrification Tank complete with n.1 submersible mixer from 1.10 Kw, complete with stainless steel propeller, stainless steel AISI 304 support and regulation rod, hot-dip galvanized steel rod fastening bracket for wall fixing, sludge recirculation pipe complete with PVC regulation valve diam. 63 mm, pipe fastening brackets, PVC pipe clamps;

- RBC Oxidation Tank complete with thick steel plates for RBC bearing anchoring, plexiglass windows complete with stainless steel fastening/sliding guides dimensions 60x30 cm, n.2 plexiglass windows complete with stainless steel fastening/sliding guides dimensions 120x60 cm, n.2 PVC gluing sleeves diam. 110, n.1 RBC with a diameter of 195 cm, disc pack length ___ cm, bearing inter-axis length ___ cm, useful surface area ___ sqm, complete with gearmotor Kw.____, with an output speed of 1.7 rpm, n.2 SKF oscillating adapter type ball bearings, n.1 thick central shaft in certified carbon steel ST-52, plates with insertion guides for hot-dip galvanized steel shafts, stainless steel shafts with relative threaded PVC plates, PP AD discs with a diameter of 170 mm;

- Sludge Sedimentation Tank (Dortmund) complete with n.1 submersible electric pump from Calpeda or similar brands (with the following minimum technical characteristics: 2-pole induction motor, 50 Hz, 230/400 V power supply, class F insulation, IP X8 protection, 0.55 kW power, 2.6/1.5 A absorption, Q= 12 mc/h - H= 6 mt, recessed vortex impeller), PVC delivery pipe, special fittings, regulation valves, PVC deflector cylinder diam. 400 complete with stainless steel support brackets, Thomson type weir trough complete with regulation and support brackets, entirely made of AISI 304 stainless steel;

- Wastewater Disinfection Tank made with a reinforced concrete pre-cast structure complete with reinforced concrete partitions, inlet and outlet, corrugated PVC fittings; dosing kit composed of n.1 electronic membrane dosing pump from Doseuro or similar brands with technical characteristics as per the technical report and adaptation to the general electrical panel for controlling the dosing pump with daily adjustable timed start-up, complete with suction system on a rod with a terminal filter;

- Aerobic Digestion Tank (sludge accumulation) complete with inlet and outlet, any corrugated PVC fittings, PVC regulation valve diam. 63 mm, pipe fastening brackets, PVC pipe clamps, self-cleaning porous micro-bubble diffusers with an EPDM membrane, downpipes and air distribution manifold made of AISI 304 stainless steel complete with a flow regulation valve on each downpipe;

- Technical Compartment made with a reinforced concrete pre-cast structure complete with a front door made of AISI 304 stainless steel with a standard lock complete with grilles to ensure minimum internal aeration, n.1 electrical panel with programmable PLC logic for controlling the various utilities.

Treatment Guarantee:

Legislative Decree 152/06 Part three, Annex 5, Table 3 "Discharge into Surface Waters", provided that the qualitative and dimensional values of the inflow to the treatment itself are respected and guaranteed.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

Biodisc Biological Waste Water Treatment System from 250 to 300 P.E. Dimensions

Download Technical Drawings

Select Article Code to access the Data Sheet for the product.

Plant Dimensional Characteristics

| Article Code |

Number P.E. |

Water supply Lt/AE/g |

Hydraulic Flow Rate daily Qg (mc/day) |

Peak Hydraulic Flow Qp mc/h |

Procapite Organic Load BOD5 gr/PE/d |

Daily Organic Load Kg BOD5/g |

Usable surface mq | Superficial organic load Co grBOD5/mq/g (approx.) |

| BIORUL250AE | 250 | 200 | 50 | 4,17 | 60 | 15 | 1.700 | 8 |

| BIORUL300AE | 300 | 200 | 60 | 5,00 | 60 | 18 | 2.261 | 8 |

Sizing

| Article Code |

Imhoff Tank (tank + cover) |

Pumping/Storage (tank + cover) |

Biodisc Oxidation (tank + cover) |

Sludge Sedimentation (Dortmund) (tank + cover) |

Wastewater Disinfection (tank + cover) |

Aerobic Digestion (tank + cover) |

Technical Compartment |

| BIORUL250AE | 246x220xH250+20 ql. 80,2 + 26,9 |

246x220xH250+10 ql. 80,2 + 13,4 |

246x370xH250+10 ql. 113,7 + 22,6 |

246x220xH250+20 ql. 90,1 + 26,9 |

125x180xH250+20 ql. 46,5 + 11,2 |

246x370xH250+20 ql. 113,7 + 45,2 |

125x110xH130 ql. 12,0 |

| BIORUL300AE | 246x270xH250+20 ql. 91,4 + 33,0 |

246x270xH250+10 ql. 91,4 + 16,5 |

246x470xH250+10 ql. 141,5 + 28,7 |

246x270xH250+20 ql. 103,0 + 33,0 |

125x180xH250+20 ql. 46,5 + 11,2 |

246x420xH250+20 ql. 124,9 + 51,3 |

125x110xH130 ql. 12,0 |

The data reported is purely indicative

It is possible to have extensions (bottomless tanks) for all of our products