Features and Operating Principle

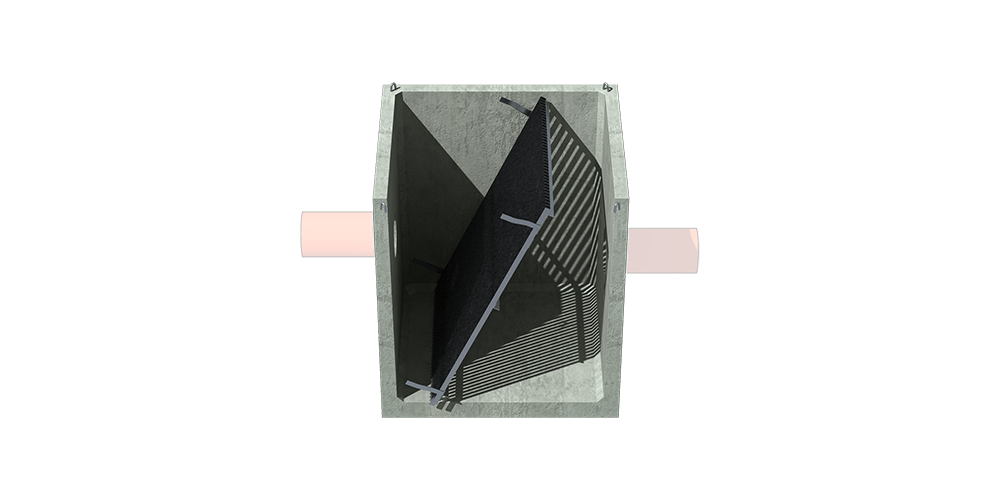

The manual Grit Chamber Manhole is constructed using a reinforced concrete manhole with an AISI 304 stainless steel screen installed inside to ensure high corrosion resistance and long life even in aggressive environments.

The dimensions of the screen and the mesh size can vary according to specific needs, for example, 40 mm pitch as standard or other combinations, in order to optimize water passage and solid retention.

The operation is simple and entirely mechanical: water and debris flow through the screen, while coarse solids are retained to be subsequently extracted manually using a comb rake provided with the unit. Consequently, the clean water flows into the drain free of particles with a diameter greater than that of the screening process.

The smooth and non-porous stainless steel surface of the screen facilitates cleaning and prevents the accumulation of residues on it, thus offering a durable solution.

The hydraulic capacity of the manhole and its load resistance vary according to the chosen model.

The removal of solids through the screening of urban and industrial wastewater is a fundamental phase in order to increase the efficiency of purification plants and to protect both the equipment and the quality of subsequent treatments.

These systems intercept and separate coarse materials, plastic, paper, textile fibers, and organic residues, which in turn cause blockages, damage, and premature wear of lifting systems, pumps, and biological systems.

The Grit Chamber Manhole represents the foundation of an efficient treatment system as it promotes the protection of aquatic ecosystems and compliance with relevant environmental regulations.

Supply specifications

Supply and installation of a Grated Manhole for underground installation, manufactured in DECLARED SERIES, code POZZ_GRIGLIAT_ ___, with external dimensions of cm.x____xh without cover, produced in DECLARED SERIES, manufactured with a management system compliant with UNI EN ISO 9001 and ISO 45001, constructed in monolithic Reinforced Concrete (R.C.) with CE-certified materials and recycled content according to the requirements indicated in the Minimum Environmental Criteria (CAM), concrete in compression resistance class C45/55 (RCK >55 N/mm²), compliant with the prescriptions of standards UNI EN 206-1 and UNI 11104 for exposure classes XC4, XS3-XD3, XF1, XA2, internal reinforcement in high-adherence steel, GREESMIX5® steel fibers (if specified), IDROCONCRETE 1200® integral system crystallizing additive for waterproof concrete (if specified), complete with certifications for Chemical Resistance and Reaction to Fire issued by an external body according to UNI EN standards. The Grit Chamber Sump is supplied complete with:

- No. 1 inlet hole DN mm;

- No. 1 outlet hole DN mm;

- Coarse stainless steel AISI 304 screen/grid, cm.xh with vertical bars, 40 mm spacing, complete with stainless steel AISI 304 rake for maintenance, installed with A2 hardware, code GRIGLIAXPOZZ XH.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

Grated Manhole Dimensions

Download Technical Drawings

Select Article Code to access the Data Sheet for the product.

| Article Code |

Grated Manhole External Dimensions (cm) |

Grated Manhole Weight (ql) |

||

| Width | Length | Height | ||

| POZZ_GRIGLIAT_0 | 100 | 100 | 100 | 10,9 |

| POZZ_GRIGLIAT_1 | 125 | 130 | 100 | 11,8 |

| POZZ_GRIGLIAT_2 | 125 | 130 | 130 | 14,2 |

| POZZ_GRIGLIAT_3 | 125 | 130 | 150 | 15,6 |

| POZZ_GRIGLIAT_4 | 175 | 180 | 150 | 23,8 |

| POZZ_GRIGLIAT_5 | 180 | 180 | 200 | 47,6 |

| POZZ_GRIGLIAT_6_H200_S10 | 246 | 220 | 200 | 68,6 |

| POZZ_GRIGLIAT_7_H250_S10 | 246 | 220 | 250 | 80,0 |

The data reported is purely indicative