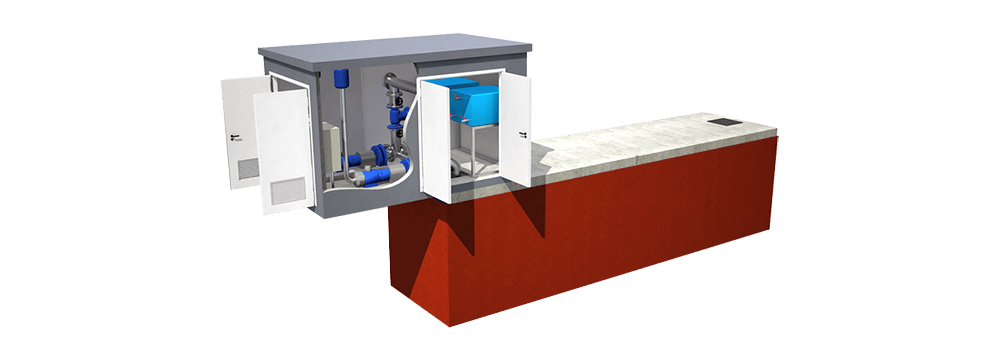

Suction Lift System with Water Reserve up to 1000 cubic meters. UNI EN 12845

Service Room and Technical Compartments UNI EN 11292:2019 for Fire-Fighting Pumping Systems

Pressurization Units

Introduction

Edil Impianti2 S.r.l. produces prefabricated tanks in fiber-reinforced vibrated reinforced concrete for Fire-Fighting Water Reserves.

Underground fire tanks are used to create storage for the water supply of suction lift fire-fighting systems.

It is possible to create fire-fighting storage reserves up to 1000 cubic meters; in addition to fire tanks, Edil Impianti2 also produces above-ground Service Compartments-Technical Rooms with R60 fire resistance class and A1 reaction class, and R60/120 doors (also A1 reaction) for access to the technical compartment where the pump sets / pre-assembled pressurization systems for fire service are installed.

The water supply for fire-fighting systems is generally regulated by the UNI EN 12845 standard regarding sprinkler systems and by the UNI 10779 standard regarding hydrant and hose reel systems.

Recently, the UNI 11292:2019 standard was issued, which specifically regulates rooms intended for housing suction lift fire-fighting units.

Prefabricated underground or above-ground fire tanks are designed and manufactured in compliance with the aforementioned regulations.

The type of water supply for the fire-fighting system must be established during the design phase based on the risk level.

The storage tank, the Service Compartment-Technical Room, and the pumping or pressurization unit that make up the fire-fighting system must be compliant and sized according to the designer's provisions and the type of supply (type and number of Electric pumps, Diesel motor pumps, flow rate, and pump head).

The entire staff and technicians of Edil Impianti2 are at the disposal of fire-fighting system designers for the optimal choice of the type of products and the quantity to be paired and arranged in order to guarantee the correct useful volume, and for the preparation of the executive drawings necessary to complete the project.

Features and Operating Principle

The Suction Lift system consists of an underground water reserve and a technical room complete with a suction lift fire-fighting unit positioned at a higher elevation that does not allow 2/3 of the useful volume to be above the axis of the main pumps. The proposed fire-fighting water storage reserves are monolithic reinforced concrete structures and can be installed underground and suitable for heavy traffic (Class 1 vehicles); the underground fire tanks are connected to each other through connection holes positioned at the bottom, in which various types of fittings with watertight gaskets, stainless steel pipe stubs or sleeves, EPDM, PVC, HDPE, etc., are inserted.

The fire-fighting monolithic blocks manufactured by Edil Impianti2 can be entirely treated with waterproof elastic cementitious paints and mortars.

These prefabricated monolithic units allow for large storage capacities capable of satisfying various requirements.

Building a fire-fighting system with prefabricated underground tanks is a fast, safe method with significant savings in construction time and high safety for workers on the construction site.

The prefabricated fire tanks produced by Edil Impianti2 can be supplied with thickened walls, increased reinforcement, and anti-buoyancy rebar.

The monolithic prefabricated concrete tanks can be supplied complete with a pressurization system inside the Service Compartment-Technical Room, which is fully equipped hydraulically and electrically, with the issuance of a certificate of declaration of conformity according to Ministerial Decree 37/2008.

The technical room is supplied complete with UNI 11292:2019 certification and anti-seismic structural documentation prepared and signed by a qualified professional, along with everything necessary to ensure the technical compartment is up to code.

Edil Impianti2 supplies pressurization units complete with testing and commissioning.

The pressurization systems installed are selected from the best brands available on the market today or based on the specific request of the designer and the final client.

Supply Specifications

The Above-Ground Firefighting System is composed as follows:

Supply and installation of a Prefabricated Underground Firefighting Water Tank/Water Reserve compliant with UNI 12845, manufactured as a DECLARED SERIES, code VASCANT_INT12845, with walls of __ cm thickness and a base of __ cm thickness. It is produced by EDIL IMPIANTI 2 S.r.l. with a UNI EN ISO 9001 and ISO 45001 management system, made of monoblock Vibrated Reinforced Concrete, reinforced with vertical pillars and horizontal stainless steel braces. It features an Elastocolor protective anti-cracking elastomeric paint on the external concrete walls, which has high permanent elasticity and high chemical resistance. The concrete is of compression resistance class C45/55 (RCK >55 N/mm²), and the internal reinforcements are made of steel with improved adhesion, controlled at the factory, and a B450C-type square-mesh electro-welded wire fabric. It is also supplied with CHEMICAL RESISTANCE and REACTION TO FIRE (class: A1) certifications issued by an external body in accordance with UNI EN standards.

N.__ x cm. ___x___xh___ + cover h__;

Total tank capacity equal to __ m³;

Internal USEFUL capacity according to UNI EN 12845 greater than __ m³.

The Underground Firefighting Tank is supplied with:

- n.1 AISI 304 stainless steel sleeve, 2" diameter, for connecting the mains water replenishment pipe;

- n.2 sleeves for 110 mm diameter PVC pipes for the creation of the overflow drain and air vent pipes;

- n.1 walkable cover slab for heavy traffic;

- 60x60 cm light inspection slots.

Supply and installation of a Prefabricated Above-Ground R60/A1 Fire Technical Room in compliance with UNI 11292 produced in DECLARED SERIES, with external dimensions of cm.___x___xh___ sloped, with walls of thickness cm.__ and a base of thickness cm.__ , manufactured by EDIL IMPIANTI 2 S.r.l. with a management system UNI EN ISO 9001 and ISO 45001, made of single-block Vibrated Reinforced Concrete, reinforced if necessary with vertical pillars and horizontal braces in stainless steel, concrete in compression resistance class C45/55 (RCK >55 N/mm²), internal reinforcement in controlled high-adherence steel and square mesh electro-welded mesh type B450C and reinforced with GREESMIX5® 3D steel fibers (Patent N.0001421398 issued by the Ministry of Economic Development), complete with CHEMICAL RESISTANCE and REACTION TO FIRE certifications (class: A1) issued by an external body according to UNI EN standards.

The Above-Ground Technical Room is supplied complete with:

- n.1 R60 access door with minimum dimensions cm.90x205 in A1 class steel sheet;

- provision for internal room ventilation;

- internal anti-wear treatment and painting (white color);

- external wall protective coating with anti-cracking elastic paint (RAL 7040 grey);

- sloped cover slab with drip edge, completely waterproofed and sealed to the technical room below.

Above-Ground Technical Compartment Set-up compliant with UNI 11292 standard complete with:

- general control panel for pressurization unit power supply and utilities;

- internal wiring of all accessories, pumps, main light + emergency light, single-phase industrial power socket;

- n. portable rechargeable emergency lamp/s with min. 2h autonomy complete with wall support shelf and signaling sign;

- natural ventilation grille/s in aluminum with fixed fins and anti-insect protective mesh;

- fan coil unit for compartment heating;

- n.1 powder extinguisher + n.1 C02 extinguisher complete with wall bracket and signaling sign;

- sprinkler protection system complete with CE marked flow switch according to EN12259-5 for alarm relay;

- sprinkler test and drain line with valve and 20 mm outlet orifice;

- microswitch for signaling the status of isolation valves;

- junction box with terminal block for alarms to be relayed to a manned location;

- double steel frame for Priming Tanks Housing;

- n.2 500 lt priming tanks;

- pump/tank priming kit complete with all piping and valves;

- fan/extractor complete with overpressure damper;

- UPS backup unit complete with batteries to ensure the operation of the fan;

- diesel motorpump exhaust fumes discharge/outdoor kit made with insulated stainless steel pipe protected with A1 class materials;

- floor water presence sensor;

- water level control and alarm kit: constant display of water storage level status and detection of minimum and maximum water level in the tank, alarm signals are available on the terminal block for relay to a manned location;

- bottom drainage for connection to the sewer system;

- ground anchoring of the pumping units to ensure their stability and alignment over time, and with mechanical characteristics capable of withstanding unit vibration during operation;

- suction lines with corresponding bend, anti-vortex plate, and filter made of AISI304;

- recirculation return line to the tank for flow rate testing made of AISI304 complete with valves;

- diaphragm circuit line complete with flow indicator UNI EN 12845 10.5 to visualize the passage of water and service during zero-flow operation, made of AISI304;

- isolation valves with position indicator and lockable UNI 11443;

- flanged manifold made of AISI304 complete with isolation valve;

- documentation related to the heating system, ventilation system, normal, emergency, and safety lighting system, back pressure of diesel engine exhaust gases, remote alarm signaling, flow diagram (P&I), equipment layout to be displayed in the compartment, use and maintenance manual with relative control lists.

All accompanied by system compliance according to Legislative Decree 37/08.

The supplied compartment will be able to maintain satisfactory temperature and humidity conditions throughout all seasons and will ensure temperature and humidity values capable of preventing dew and/or condensation formation.

Pre-assembled Fire Pump Set according to UNI EN 12845 (Above/Below Water Level Suction) composed of:

N° 1 main electric pump,

N° 1 main diesel pump, and one jockey pump.

The operation of the main pump modules (PUMP SET) is completely independent.

In case of a pressure drop that cannot be compensated by the limited flow rate of the pilot electric pump (jockey pump), the main pump starts automatically.

The shut-down of the main pump is **manual only** via a switch on its respective control panel, as required by UNI EN 12845. Automatic shut-down of the main pumps is only permitted for sets exclusively serving hydrant systems according to UNI 10779, based on the criteria outlined in UNI 10779 A 1.2.

MAIN ELECTRIC PUMP

END SUCTION, single-impeller, normalized centrifugal pump, horizontal axis, **BACK PULL OUT** type, with volute casing and independent bearing frame; axial suction and radial discharge UNI EN 12845 10.1

Pump Casing in Cast Iron EN GJL 250

Impeller and Shaft in Stainless Steel

Mechanical Seal in ceramic/graphite

Pump-Motor connection via a spacer flexible coupling complete with safety guard UNI EN 12845 10.1

Pump/Motor set installed on a base frame made of metallic profiles, connection via a spacer flexible coupling, complete with safety guard UNI EN 12845 10.1

ELECTRIC MOTOR

Three-phase asynchronous, closed, externally self-ventilated motor with squirrel cage rotor

INSTALLED POWER (kW) __ Power calculated based on the power absorbed at the point on the characteristic curve corresponding to an NPSH of 16m UNI EN 12845 10.1

FLOW RATE (m³/h) __

HEAD (mca) __ (metres of water column)

NPSH (m) __

VOLTAGE 400/690 V, 50Hz

PROTECTION RATING IP 55

ROTATION SPEED 2900 rpm (revolutions per minute).

MAIN DIESEL PUMP SET

Pump/Motor set installed on a base frame made of metallic profiles, connection via a universal joint (cardan shaft) complete with safety guard UNI EN 12845 10.1

INTERNAL COMBUSTION ENGINE

The engine power is the **NOMINAL CONTINUOUS** power dimensioned according to ISO 3046 in compliance with UNI EN 12845 10.9.1

INSTALLED POWER (kW)__ in NA curve Power calculated based on the power absorbed at the point on the characteristic curve corresponding to an NPSH of 16m UNI EN 12845 10.1

MAKE AND MODEL ____ or similar with direct air cooling

FLOW RATE (m³/h) __

HEAD (mca) __

NPSH (m) __

ROTATION SPEED 2900 rpm

Double-walled TANK on stand __ l with inner wall in AISI 304 UNI 11292 7.2.

JOCKEY PUMP

Jockey Pump kit kW _ at __ mca

Pump Casing and Motor Support in Cast Iron

Impeller in Brass

Diffuser in Noryl

Shaft in Stainless Steel

Mechanical Seal in ceramic/graphite

Three-phase asynchronous ELECTRIC MOTOR

INSTALLED POWER (kW) __

VOLTAGE 400 V 50Hz

ROTATION SPEED 2900 rpm.

MAIN ELECTRIC PUMP CONTROL PANEL

The electrical panel controls and monitors pump sets with electric and diesel pumps compliant with UNI EN 12845.

Assembled in a painted sheet metal enclosure with IP54 protection rating, built according to current CEI standards and compliant with the requirements of UNI EN 12845.

MAIN FEATURES

High vibration resistance

USB type A port for downloading stored data

Jockey pump monitoring (see jockey pump panel) Water storage tank level monitoring

Valve position monitoring

Sprinkler flow switch monitoring

Local drainage pump monitoring

Ambient temperature visible on display

Engine bulb monitoring

Oil and water temperature visible on display

Oil pressure visible on display

Message screen.

GENERAL FEATURES

Power supply 3P+N 400V±10% 50/60Hz

N°2 Battery chargers for charging and controlling batteries 6A 12Vdc for engines up to 102kW, 10A 12Vdc for engines up to 222kW, 10A 24Vdc for engines over 222kW

Engine Inhibition Switch “0 – 1”

4-20 mA signal input from level transmitter

Emergency start buttons from battery

Contactors dimensioned in AC3

Class II Transformer

Motor protection fuses

Auxiliary protection fuses

General disconnector with door interlock

Metallic enclosure

Terminal block User Manual

Wiring diagram and EC declaration.

WIRING ELECTRIC CABLES

The wiring within the set is made with FG16 OM16-0.6/1 kV type cables.

DISCHARGE MANIFOLD

The manifold consists of the following components:

N°1 lug-type butterfly isolation valve with position indicator, possibility of locking, and manual gearbox where required

N°1 inspectable check valve (non-return valve) of the swing-check type with reduced pressure losses

N°1 diaphragm recirculation circuit (continuous water flow) for cooling the main pumps during zero-flow operation, thereby preventing the pumps from overheating. UNI EN 12845 10.5.

DUAL PRESSURE SWITCH CIRCUIT

This component is required for the automatic starting of each main pump UNI EN 10.7.5.

Each circuit is composed of:

N°2 dual-scale pressure switches

N°1 pressure gauge class 1.6 Diameter 80 EN 12845 8.5.2 TR/11438:2016 6.1.4

N°1 check valve (non-return valve)

N°1 drain valve

JOCKEY PUMP AUTOMATIC START AND STOP CIRCUIT

The circuit is composed of:

N°1 dual-scale pressure switch

N°1 pressure gauge class 1.6

N°1 check valve

N°1 isolation valve

N°1 20 l / 16 bar diaphragm tank (pressure tank)

TIMED SHUTDOWN UNI 10779

REMOTE ALARM ELECTRICAL PANEL UNI EN 12845 10.8.6.2

The electrical panel performs remote supervision of pump sets with diesel pumps, electric pumps, and emergency power supplies compliant with UNI EN 12845.

Possibility of integrating a GSM message sending board (upon request).

Supplied loose, to be installed on-site by the installer.

To be installed in a permanently manned area UNI EN 12845 10.8.6.2.

FLOW METER WITH ANTI-CLOGGING CIRCUIT

Remote reading flow meter DN__ - up to __m³/h UNI EN 12845 8.5.2 for vertical/horizontal installation. Accuracy ~ 5% of full-scale value.

FUEL TANK UNI EN 12845 10.9.6 - UNI 11292 6.10.1

Double-walled fuel tank, with inner wall made of stainless steel to eliminate the risk of pipe clogging due to oxidation residues, capable of ensuring an operating autonomy of 6 hours at full power.

SUCTION MICROSWITCH KIT

Limit switches for ON/OFF status monitoring of the main pump suction valves As per UNI EN 12845 H2.2

DISCHARGE MICROSWITCH KIT

Limit switches for ON/OFF status monitoring of the main pump discharge valves As per UNI EN 12845 H2.2.

The supply includes the following Fire Protection Documentation:

- electrical design by a qualified professional;

- internal lighting design by a qualified professional;

- internal ventilation and temperature design by a qualified professional;

- plumbing declaration of conformity (Di.Co) according to D.M. 37/2008;

- electrical declaration of conformity (Di.Co) according to D.M. 37/2008;

- operation and maintenance manual for the installed machines and the technical room;

- as-built layout project and P&ID flow diagram.

Specific report for fire reaction and resistance R60 signed by our qualified technician.

Fees, payments, duty stamps, and filing with public offices are excluded.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

Overfloor Fire Protection Dimensions

To view the product dimensions, please refer to the measurements of the Precast Concrete Tank and its Extensions and Cover Slabs.