Civil Wastewater Treatment

Static Degreaser Grease Separator - aerated with Enzymes

Precast in reinforced concrete

Compliant with the UNI EN 1825 standard

Monoblock Degreaser Civil Residence Grease Separator - Production Activities

Features and operating principle

The concrete Degreaser is used for all activities where a large amount of grease is processed - vegetable and animal oils, degreasers for catering groups, school food service, catering services.

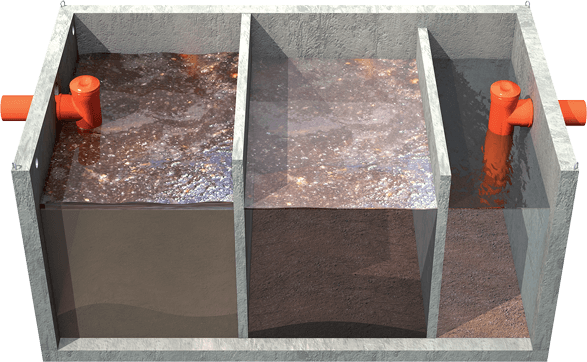

The concrete degreaser or grease condenser is a concrete calming tank where oils, grease and foam can float based on physical separation mechanisms. The concrete degreaser for animal and vegetable oils and fats (sometimes called Degreaser, Deoiler or De-oiler) is installed before the primary treatment system (concrete Imhoff tanks) and organic treatment systems, or right where vegetable and animal oils and fats - as well as detergents - are discharged.

Their removal is necessary before letting in any natural waterbody due to the negative effects on flora and fauna.

Biogas produced during fermentation is released through the side vents next to the inlet opening, which must always be connected and led to the top cover.

Treated wastewater cleaned by the grease separator will flow into the Imhoff tank. The concrete degreaser is effective if installed with the right dimensions (from 50 /100 lt. for Equivalent Inhabitant).

These are also commonly called: grease condensers or trap wells.

A degreaser for restaurant kitchens - also grease condenser - hotels, hospitals, homes, is a concrete calm tank where oils, fats and foams can float based on physical separation principles. The degreaser for oils, animal and vegetable fats is s installed before the primary treatment system (concrete Imhoff tanks) and organic treatment systems, or right where vegetable and animal oils and fats - as well as detergents - from restaurants, canteens, hospitals, hotels, camping areas and holiday resorts are discharged. Their removal is necessary before letting in any natural waterbody due to the negative effects on flora and fauna.

Biogas produced during fermentation is released through the side vents next to the inlet opening, which must always be connected and led to the top cover.

Treated water cleaned by the grease separator will flow into the Imhoff tank.

The concrete degreaser and grease condenser is effective if installed with the correct dimensions (from 50 lt. / meal served per day).

Regularly check the grease layer and crust level accumulated in the tank from the specific inspection holes; Cleaning shall be performed, with frequency depending on the oil, grease and detergent load in the incoming water), by a specialized company - gully emptier - that can issue specific documents and the cleaning frequency will depend on the oil, grease and cleaning agents load in the incoming waste water. The cleaning company's documents will have to be preserved for at least 5 years with the system itself; Perform cleaning through the specific inspection holes.

Product disposal will have to be performed in full compliance with the environmental regulations in force when disposing of the product. The Client shall be fully aware of the prescribed procedures defined based on the current regulations and therefore hold Edil Impianti 2 S.r.l. harmless from any disposal issue.

Degreaser prices for restaurants and residential purposes by Edilimpianti include inlets and outlets, PVC tube fittings with waterproof elastomer rubber gaskets, PVC stilling baffles, vents with fitting and PVC sleeve sealing, suitable internal epoxy resin coating and external coating.

The commercial semi-finished degreaser prices do not include all of the necessary components to complete the finished product, the final prices will be calculated by the company or technician and can be compared with a completely finished degreaser. Precast concrete degreasers do not need any external reinforcement if compared to polyethylene or plastic degreasers, nor do they need to be filled with water during the installation, but, most importantly, they do not break during maintenance operations and crust removal and inspections are thorough to clean the degreaser everywhere.

Dimensions

Dimensions for Civil Residence / Restaurants / Hotels / Canteens / Catering Services:

For Civil Residence with lt. 50 - 25 per population equivalent;

For Manufacturing Activities with lt. 25 - 20 - 15 per meal/day.

Fields of application

Civil residence systems, slaughterhouses, wine cellars, cheese factories, food industry, conservation industry, pasta manufacturers, pastry manufacturers, fish industry, laundry services, civil residence, blocks, restaurants, hotels, hospitals, communities, canteens, catering services, schools, bars, camping sites, bathing establishments, service stations, meal production centers.

Suggestions and technical information

The Degreaser and the concrete Imhoff Tank are a primary pre-treatment and, in case it is required by the executive project or the authorization to drain, they must be integrated with secondary treatment systems such as: biodiscs, activated sludges, phytopurification with vertical or horizontal flow, MBBR, SBR, aerobic and anaerobic percolator filters.

Regulation

Leg. Decree 152/06 and resolution of the Emilia-Romagna Regional Council 1053/2003 domestic wastewater not discharged into public sewers, discharge into surface water.

HOW TO CALCULATE THE POPULATION EQUIVALENT (P.E.)

CIVIL RESIDENCE counting beds: 1 P. E. for bedrooms with up to 13.90 sqm surface; 2 P. E. for bedrooms with over 14 sqm surface.

HOTEL or ACCOMMODATION STRUCTURE the same as for civil residence, just add 1 P. E. when the room surface is +6 sqm over 14 sqm.

for vacation structures or special situations where the seasonal use causes strong population density, it is necessary to consider the maximum effective potential of the structure.

RESTAURANTS to calculate the population equivalent, it is necessary to estimate the maximum accommodation capacity of the dining rooms, considering that a person takes around 1.20 sqm, together with the guests, you have to count the staff as well.

1 P.E. every 3 people.

Technology

For any residential unit or production plant where meals are provided and dishes washed, it is recommended to have wastewater and WC (sewage water) lines separated from sink, washbasin, shower, washing machines, dishwasher (grey water) lines.

Sewage water must be sent directly into the Imhoff tank, whereas grey waters with oil, grease and detergents must be sent into the static grease separator first and then into the Imhoff tank or directly into the public sewage system, if connected with the local authority water purification plant.

DIMENSIONING WITH WATER SUPPLY STARTING FROM MIN. 20 LT. UP TO 50 LT.

Degreasers must have a water supply of at least 20 lt. per meal served/ a day for kitchen waters in companies, restaurants, hotels, canteens, whereas degreasers for civil residence at least 50 lt. per Population Equivalent as per Regional Resolution No. 1053 of June 2003.

Degreasers with smaller volumes cause management problems for the user, as maintenance interventions are required more frequently, thus causing interruptions during maximum productivity time. Therefore, concrete degreasers are crucial, but most importantly degreasers must be the right size to avoid problems and cost increase for the user.

For correct functioning, some construction requirements are necessary: the partition wall between the upper compartment (oil and grease collector) must have a variable height between 1/2 and 1/4 if compared to the tank water column height, whereas the ratio between surface area and water column height must have a minimum 0.35 sqm/mt value for grease condensers having up to 1000 lt capacity and a minimum 1 sqm/mt value for capacities over 1000 lt.

Supply specifications

Supply and installation of underground Static Degreaser / Grease Separator for Civil Residence - Kitchens, CE marked and manufactured in DECLARED SERIES, Mod. DEGSEPC___ or SEPGRA-MK__ (Miniblock version), compliant with the UNI EN 1825-1 standard, nominal dimensions NS____ lt/sec, effective volume _____ lt, ____P.E. (Liters 50xP.E.) Emilia-Romagna Region, ____P.E. (Liters 25xP.E.), manufactured by EDIL IMPIANTI 2 S.r.l. with UNI EN ISO 9001 and ISO 45001 management system made of monoblock vibrated concrete, reinforced with vertical pillars and stainless steel horizontal beams, with CE-certified materials, concrete in compressive strength class C45/55 (RCK >55 N/mm²), internal improved-adhesion steel reinforcements checked in our plant, GREESMIX5® steel fibers (patent No. 0001421398 issued by the Ministry for Economic Development) and electro-welded square mesh B450C, with certification of CHEMICAL RESISTANCE and REACTION TO FIRE (Class A1) issued by an external body based on UNI EN standards.

The CE-marked Static Degreaser/ Grease Separator for Civil Residence is equipped with:

inlets/outlets; inlet-side vents; partition/s for bicameral and tricameral compartments; outer wall protective coating.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

Static Degreaser Dimensions / Grease Separator for Civil Residence

Emilia-Romagna region - Umbria Region, with 50 lt / P.E. (Population Equivalent)

Download Technical Drawings

Select Article Code to access the Data Sheet for the product.

| Article Code |

NS (Nominal Dimension) |

Usable Volume (lt) |

lt.25 for P.E. |

lt.50 for P.E. |

External Dimensions Degreaser (cm) |

Tank Weight (ql) |

Cover slab weight (ql) | ||||

| Width | Length | Height | h. 10 cm (B125) |

h. 15 cm (C250) |

h. 20 cm (D400) |

||||||

| DEGSEPCB1A | 0,5 | 150 | 6 | 3 | 70 | 70 | 75 | 3,8 | 0,9 | 1,8 | - |

| DEGSEPCB2 | 0,7 | 250 | 10 | 5 | 70 | 70 | 90 | 4,3 | 0,9 | 1,8 | - |

| DEGSEPCB_080 | 1,0 | 300 | 12 | 6 | 80 | 80 | 85 | 4,1 | 1,3 | 2,4 | 3,2 |

| DEGSEPCB2B | 1,0 | 400 | 16 | 8 | 90 | 90 | 75 | 4,3 | 1,6 | 3,2 | 4,0 (on request) |

| DEGSEPCB2C | 1,2 | 500 | 20 | 10 | 90 | 90 | 100 | 5,6 | 1,6 | 3,2 | 4,0 (on request) |

| DEGSEPCB2D | 1,5 | 600 | 24 | 12 | 100 | 100 | 100 | 6,4 | 2,5 | 3,7 | 5,0 |

| DEGSEPCB3B | 2,5 | 850 | 34 | 17 | 125 | 130 | 100 | 12,9 | 4,0 | 6,1 | 8,1 |

| DEGSEPCB4 | 2,7 | 1.250 | 50 | 25 | 125 | 130 | 130 | 15,8 | 4,0 | 6,1 | 8,1 |

| DEGSEPCB5 | 3 | 1.500 | 60 | 30 | 125 | 130 | 150 | 17,5 | 4,0 | 6,1 | 8,1 |

| DEGSEPCB5A | 4 | 1.750 | 70 | 35 | 125 | 180 | 130 | 19,3 | 5,6 | 8,4 | 11,2 |

| DEGSEPCB6 | 5 | 2.150 | 86 | 43 | 125 | 180 | 150 | 21,4 | 5,6 | 8,4 | 11,2 |

| DEGSEPCB7B | 6 | 2.500 | 100 | 50 | 175 | 180 | 130 | 24,2 | 7,8 | 11,7 | 15,6 |

| DEGSEPCB7 | 7 | 3.000 | 120 | 60 | 175 | 180 | 150 | 26,7 | 7,8 | 11,7 | 15,6 |

| DEGSEPCB8 | 10 | 4.000 | 160 | 80 | 180 | 240 | 150 | 52,4 | 10,7 | 16,1 | 21,5 |

| DEGSEPCT9 | 13 | 5.000 | 200 | 100 | 180 | 300 | 150 | 65,4 | 13,4 | 20,1 | 26,8 |

| DEGSEPCB9A | 10 | 4.000 | 160 | 80 | 180 | 180 | 200 | 54,9 | 8,0 | 12,1 | 16,1 |

| DEGSEPCB9B | 13 | 5.000 | 200 | 100 | 180 | 220 | 200 | 61,8 | 9,8 | 14,8 | 19,7 |

| DEGSEPCT10 | 15 | 6.200 | 248 | 124 | 180 | 270 | 200 | 76,0 | 12,1 | 18,1 | 24,1 |

| DEGSEPCT10A | 17 | 7.500 | 300 | 150 | 180 | 320 | 200 | 84,4 | 14,3 | 21,5 | 28,6 |

| DEGSEPCT11A | 20 | 9.000 | 360 | 180 | 180 | 370 | 200 | 92,8 | 16,5 | 24,8 | 33,1 |

| DEGSEPCB13D | 15 | 7.000 | 280 | 140 | 246 | 220 | 200 | 78,7 | 13,4 | 20,2 | 26,9 |

| DEGSEPCB13E | 18 | 9.000 | 360 | 180 | 246 | 270 | 200 | 88,6 | 16,5 | 24,7 | 33,0 |

| DEGSEPCT14B | 20 | 10.500 | 420 | 210 | 246 | 320 | 200 | 106,9 | 19,6 | 29,3 | 39,1 |

| DEGSEPCT15B | 25 | 12.500 | 500 | 250 | 246 | 370 | 200 | 116,8 | 22,6 | 33,9 | 45,2 |

| DEGSEPCT16B | 30 | 14.000 | 560 | 280 | 246 | 420 | 200 | 126,7 | 25,7 | 38,5 | 51,3 |

| DEGSEPCT17B | 35 | 16.000 | 640 | 320 | 246 | 470 | 200 | 140,8 | 28,7 | 43,1 | 57,4 |

| DEGSEPCT18B | 40 | 18.000 | 720 | 360 | 246 | 520 | 200 | 150,7 | 31,8 | 47,7 | 63,6 |

| DEGSEPCT19B | 45 | 20.000 | 800 | 400 | 246 | 570 | 200 | 160,6 | 34,8 | 52,2 | 69,7 |

| DEGSEPCT20B | 50 | 21.000 | 840 | 420 | 246 | 620 | 200 | 170,6 | 37,9 * | 56,8 * | 75,8 * |

| DEGSEPCT21B | 55 | 22.700 | 908 | 454 | 246 | 670 | 200 | 180,5 | 40,9 * | 61,4 * | 81,9 * |

| DEGSEPCT22B | 60 | 24.500 | 980 | 490 | 246 | 720 | 200 | 194,7 | 44,0 * | 66,0 * | 88,0 * |

| DEGSEPCT23B | 65 | 26,000 | 1.040 | 520 | 246 | 770 | 200 | 204,6 | 47,1 * | 70,6 * | 94,1 * |

| DEGSEPCT24B | 70 | 28.000 | 1.120 | 560 | 246 | 820 | 200 | 214,5 | 50,1 * | 75,2 * | 100,2 * |

| DEGSEPCT25B | 75 | 29.500 | 1.180 | 590 | 246 | 870 | 200 | 224,4 | 53,2 * | 79,7 * | 106,3 * |

| DEGSEPCT26B | 80 | 31.500 | 1.260 | 630 | 246 | 920 | 200 | 234,3 | 56,2 * | 84,3 * | 112,4 * |

| DEGSEPCT27B | 86 | 33.000 | 1.320 | 660 | 246 | 970 | 200 | 248,4 | 59,3 * | 88,9 * | 118,5 * |

| DEGSEPCT28B | 90 | 35.000 | 1.400 | 700 | 246 | 1020 | 200 | 258,2 | 62,3 * | 93,5 * | 124,7 * |

* Cover Slab divided into two parts

The data reported is purely indicative

Supply specifications

Delivery and installation of CE-marked Static Degreaser / Grease Separator for Manufacturing Activities - Kitchens - Restaurants - Canteens - Underground hospitals in DECLARED SERIES, Mod. DEGSEPR___ or SEPGRA-MK__ (Miniblock version), compliant with the UNI EN 1825-1 standard, external dimensions: cm.____x____xh____ , effective volume _____ lt, No. of meals/days ___ (25 Liters x meals/days), No. of meals/days ___ (20 Liters x meals/days), No. of meals/days ___ (15 Liters x meals/days), manufactured by EDIL IMPIANTI 2 S.r.l. with UNI EN ISO 9001 and ISO 45001 management system made of monoblock vibrated concrete, reinforced with vertical pillars and stainless steel horizontal beams, with CE-certified materials, concrete in compressive strength class C45/55 (RCK >55 N/mm²), internal improved-adhesion steel reinforcements checked in our plant, GREESMIX5® steel fibers (patent No. 0001421398 issued by the Ministry for Economic Development) and electro-welded square mesh B450C, with certification of CHEMICAL RESISTANCE and REACTION TO FIRE (Class A1) issued by an external body based on UNI EN standards.

The CE-marked Static Degreaser/ Grease Separator for Civil Residence is equipped with:

inlets/outlets; inlet-side vents; partition/s for bicameral and tricameral compartments; outer wall protective coating.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

Static Degreaser Dimensions / Grease Separator for Production Activities

Download Technical Drawings

Select Article Code to access the Data Sheet for the product.

| Article Code |

NS (Nominal Dimension) |

Usable Volume (lt) |

lt.25 daily Meal |

lt.20 daily Meal |

lt.15 daily Meal |

External Dimensions Degreaser (cm) |

Tank Weight (ql) |

Cover slab weight (ql) | ||||

| Width | Length | Height | h. 10 cm (B125) |

h. 15 cm (C250) |

h. 20 cm (D400) |

|||||||

| DEGSEPRB0 | 0,7 | 250 | 10 | 12 | 16 | 70 | 70 | 90 | 4,3 | 0,9 | 1,8 | - |

| DEGSEPRB_080 | 1,0 | 300 | 12 | 15 | 20 | 80 | 80 | 85 | 4,1 | 1,3 | 2,4 | 3,2 |

| DEGSEPRB0A | 1,0 | 400 | 16 | 20 | 26 | 90 | 90 | 75 | 4,3 | 1,6 | 3,2 | 4,0 (on request) |

| DEGSEPRB0B | 1,2 | 500 | 20 | 25 | 33 | 90 | 90 | 100 | 5,6 | 1,6 | 3,2 | 4,0 (on request) |

| DEGSEPRB0C | 1,5 | 600 | 24 | 30 | 40 | 100 | 100 | 100 | 6,4 | 2,5 | 3,7 | 5,0 |

| DEGSEPRB1A | 2,5 | 850 | 34 | 42 | 56 | 125 | 130 | 100 | 12,9 | 4,0 | 6,1 | 8,1 |

| DEGSEPRB2 | 2,7 | 1.250 | 50 | 62 | 83 | 125 | 130 | 130 | 15,8 | 4,0 | 6,1 | 8,1 |

| DEGSEPRB5 | 3 | 1.500 | 60 | 75 | 100 | 125 | 130 | 150 | 17,5 | 4,0 | 6,1 | 8,1 |

| DEGSEPRB6A | 4 | 1.750 | 70 | 87 | 116 | 125 | 180 | 130 | 19,3 | 5,6 | 8,4 | 11,2 |

| DEGSEPRB6 | 5 | 2.150 | 86 | 107 | 143 | 125 | 180 | 150 | 21,4 | 5,6 | 8,4 | 11,2 |

| DEGSEPRB7B | 6 | 2.500 | 100 | 125 | 166 | 175 | 180 | 130 | 24,2 | 7,8 | 11,7 | 15,6 |

| DEGSEPRB7 | 7 | 3.000 | 120 | 150 | 200 | 175 | 180 | 150 | 26,7 | 7,8 | 11,7 | 15,6 |

| DEGSEPRB8 | 10 | 4.000 | 160 | 200 | 266 | 180 | 240 | 150 | 52,4 | 10,7 | 16,1 | 21,5 |

| DEGSEPRT9 | 13 | 5.000 | 200 | 250 | 333 | 180 | 300 | 150 | 65,4 | 13,4 | 20,1 | 26,8 |

| DEGSEPRB9A | 10 | 4.000 | 160 | 200 | 266 | 180 | 180 | 200 | 54,9 | 8,0 | 12,1 | 16,1 |

| DEGSEPRB9B | 13 | 5.000 | 200 | 250 | 333 | 180 | 220 | 200 | 61,8 | 9,8 | 14,8 | 19,7 |

| DEGSEPRT10 | 15 | 6.200 | 248 | 310 | 413 | 180 | 270 | 200 | 76,0 | 12,1 | 18,1 | 24,1 |

| DEGSEPRT10A | 17 | 7.500 | 300 | 375 | 500 | 180 | 320 | 200 | 84,4 | 14,3 | 21,5 | 28,6 |

| DEGSEPRT11A | 20 | 9.000 | 360 | 450 | 600 | 180 | 370 | 200 | 92,8 | 16,5 | 24,8 | 33,1 |

| DEGSEPRB13D | 15 | 7.000 | 280 | 350 | 466 | 246 | 220 | 200 | 78,7 | 13,4 | 20,2 | 26,9 |

| DEGSEPRB13E | 18 | 9.000 | 360 | 450 | 600 | 246 | 270 | 200 | 88,6 | 16,5 | 24,7 | 33,0 |

| DEGSEPRT14B | 20 | 10.500 | 420 | 525 | 700 | 246 | 320 | 200 | 106,9 | 19,6 | 29,3 | 39,1 |

| DEGSEPRT15B | 25 | 12.500 | 500 | 635 | 833 | 246 | 370 | 200 | 116,8 | 22,6 | 33,9 | 45,2 |

| DEGSEPRT16B | 30 | 14.000 | 560 | 700 | 933 | 246 | 420 | 200 | 126,7 | 25,7 | 38,5 | 51,3 |

| DEGSEPRT17B | 35 | 16.000 | 640 | 800 | 1.066 | 246 | 470 | 200 | 140,8 | 28,7 | 43,1 | 57,4 |

| DEGSEPRT18B | 40 | 18.000 | 720 | 900 | 1.200 | 246 | 520 | 200 | 150,7 | 31,8 | 47,7 | 63,6 |

| DEGSEPRT19B | 45 | 20.000 | 800 | 1.000 | 1.333 | 246 | 570 | 200 | 160,6 | 34,8 | 52,2 | 69,7 |

| DEGSEPRT20B | 50 | 21.000 | 840 | 1.050 | 1.400 | 246 | 620 | 200 | 170,6 | 37,9 * | 56,8 * | 75,8 * |

| DEGSEPRT21B | 55 | 22.700 | 908 | 1.135 | 1.513 | 246 | 670 | 200 | 180,5 | 40,9 * | 61,4 * | 81,9 * |

| DEGSEPRT22B | 60 | 24.500 | 980 | 1.225 | 1.633 | 246 | 720 | 200 | 194,7 | 44,0 * | 66,0 * | 88,0 * |

| DEGSEPRT23B | 65 | 26.000 | 1.040 | 1.300 | 1.733 | 246 | 770 | 200 | 204,6 | 47,1 * | 70,6 * | 94,1 * |

| DEGSEPRT24B | 70 | 28.000 | 1.120 | 1.400 | 1.866 | 246 | 820 | 200 | 214,5 | 50,1 * | 75,2 * | 100,2 * |

| DEGSEPRT25B | 75 | 29.500 | 1.180 | 1.475 | 1.966 | 246 | 870 | 200 | 224,4 | 53,2 * | 79,7 * | 106,3 * |

| DEGSEPRT26B | 80 | 31.500 | 1.260 | 1.575 | 2.100 | 246 | 920 | 200 | 234,3 | 56,2 * | 84,3 * | 112,4 * |

| DEGSEPRT27B | 86 | 33.000 | 1.320 | 1.650 | 2.200 | 246 | 970 | 200 | 248,4 | 59,3 * | 88,9 * | 118,5 * |

| DEGSEPRT28B | 90 | 35.000 | 1.400 | 1.750 | 2.333 | 246 | 1020 | 200 | 258,2 | 62,3 * | 93,5 * | 124,7 * |

| DEGSEPRB12 | 18 | 9.200 | 368 | 460 | 613 | 246 | 220 | 250 | 93,3 | 13,4 | 20,2 | 26,9 |

| DEGSEPRB13 | 23 | 11.500 | 460 | 575 | 766 | 246 | 270 | 250 | 104,5 | 16,5 | 24,7 | 33,0 |

| DEGSEPRT14 | 33 | 15.000 | 600 | 750 | 1.000 | 246 | 320 | 250 | 126,8 | 19,6 | 29,3 | 39,1 |

| DEGSEPRT15 | 35 | 16.000 | 640 | 800 | 1.066 | 246 | 370 | 250 | 138,0 | 22,6 | 33,9 | 45,2 |

| DEGSEPRT16 | 40 | 18.500 | 740 | 925 | 1.233 | 246 | 420 | 250 | 149,2 | 25,7 | 38,5 | 51,3 |

| DEGSEPRT17 | 50 | 21.000 | 840 | 1.050 | 1.400 | 246 | 470 | 250 | 165,8 | 28,7 | 43,1 | 57,4 |

| DEGSEPRT18 | 55 | 23.000 | 920 | 1.150 | 1.533 | 246 | 520 | 250 | 177,0 | 31,8 | 47,7 | 63,6 |

| DEGSEPRT19 | 65 | 25.500 | 1.020 | 1.275 | 1.700 | 246 | 570 | 250 | 188,2 | 34,8 | 52,2 | 69,7 |

| DEGSEPRT20 | 70 | 28.000 | 1.120 | 1.400 | 1.866 | 246 | 620 | 250 | 199,4 | 37,9 * | 56,8 * | 75,8 * |

| DEGSEPRT21 | 75 | 30.000 | 1.200 | 1.500 | 2.000 | 246 | 670 | 250 | 210,5 | 40,9 * | 61,4 * | 81,9 * |

| DEGSEPRT22 | 80 | 32.000 | 1.280 | 1.600 | 2.133 | 246 | 720 | 250 | 227,1 | 44,0 * | 66,0 * | 88,0 * |

| DEGSEPRT23 | 90 | 35.000 | 1.400 | 1.750 | 2.333 | 246 | 770 | 250 | 238,3 | 47,1 * | 70,6 * | 94,1 * |

| DEGSEPRT24 | 95 | 37.000 | 1.480 | 1.850 | 2.466 | 246 | 820 | 250 | 249,5 | 50,1 * | 75,2 * | 100,2 * |

| DEGSEPRT25 | 100 | 39.000 | 1.560 | 1.950 | 2.600 | 246 | 870 | 250 | 260,7 | 53,2 * | 79,7 * | 106,3 * |

| DEGSEPRT26 | 107 | 41.500 | 1.660 | 2.075 | 2.766 | 246 | 920 | 250 | 271,9 | 56,2 * | 84,3 * | 112,4 * |

| DEGSEPRT27 | 114 | 44.000 | 1.760 | 2.200 | 2.933 | 246 | 970 | 250 | 288,5 | 59,3 * | 88,9 * | 118,5 * |

| DEGSEPRT28 | 120 | 46.000 | 1.840 | 2.300 | 3.066 | 246 | 1020 | 250 | 299,6 | 62,3 * | 93,5 * | 124,7 * |

| DEGSEPRM30A | 130 | 50.000 | 2.000 | 2.500 | 3.333 | 246 | 870 | 300 | 266,3 | 53,2 * | 79,7 * | 106,3 * |

| DEGSEPRM31A | 133 | 51.000 | 2.040 | 2.550 | 3.400 | 246 | 920 | 300 | 286,5 | 56,2 * | 84,3 * | 112,4 * |

| DEGSEPRM32A | 144 | 55.000 | 2.200 | 2.750 | 3.666 | 246 | 970 | 300 | 298,8 | 59,3 * | 88,9 * | 118,5 * |

| DEGSEPRM33A | 152 | 58.000 | 2.320 | 2.900 | 3.866 | 246 | 1020 | 300 | 311,1 | 62,3 * | 93,5 * | 124,7 * |

* Cover Slab divided into two parts

The data reported is purely indicative

Static Degreaser Measurements / Grease Separator - Miniblock version

Civil Residence (lt. 50xE.P.) e Production Activities (lt.10/15 meal/day)

Download Technical Drawings

Select Article Code to access the Data Sheet for the product.

| Article Code |

NS (Nominal Dimension) |

Usable Volume (lt) |

lt.50 for P.E. |

lt.10 daily Meal |

lt.15 daily Meal |

External Dimensions Oils & Grease Separator (cm) |

Tank Weight (ql) |

Cover slab weight (ql) | ||||

| Width | Length | Height | h. 10 cm (B125) |

h. 15 cm (C250) |

h. 20 cm (D400) |

|||||||

| SEPGRA-MK1A | 2,5 | 1.000 | 20 | 100 | 66 | 120 | 170 | 100 | 22,0 | 5,0 | 8,0 | 10,0 |

| SEPGRA-MK2A | 3 | 1.300 | 26 | 130 | 86 | 120 | 220 | 100 | 26,0 | 7,0 | 10,0 | 13,0 |

| SEPGRA-MK3A | 4 | 1.600 | 32 | 160 | 106 | 120 | 270 | 100 | 31,0 | 8,0 | 12,0 | 16,0 |

| SEPGRA-MK4A | 5 | 2.000 | 40 | 200 | 133 | 120 | 320 | 100 | 35,0 | 10,0 | 14,0 | 19,0 |

| SEPGRA-MK1B | 4 | 1.700 | 34 | 170 | 113 | 120 | 170 | 150 | 30,0 | 5,0 | 8,0 | 10,0 |

| SEPGRA-MK2B | 5 | 2.300 | 46 | 230 | 153 | 120 | 220 | 150 | 36,0 | 7,0 | 10,0 | 13,0 |

| SEPGRA-MK3B | 7 | 2.900 | 58 | 290 | 193 | 120 | 270 | 150 | 42,0 | 8,0 | 12,0 | 16,0 |

| SEPGRA-MK4B | 8 | 3.400 | 68 | 340 | 226 | 120 | 320 | 150 | 47,0 | 10,0 | 14,0 | 19,0 |

| SEPGRA-MK1C | 6 | 2.500 | 50 | 250 | 166 | 120 | 170 | 205 | 39,0 | 5,0 | 8,0 | 10,0 |

| SEPGRA-MK2C | 8 | 3.400 | 68 | 340 | 226 | 120 | 220 | 205 | 46,0 | 7,0 | 10,0 | 13,0 |

| SEPGRA-MK3C | 10 | 4.200 | 84 | 420 | 280 | 120 | 270 | 205 | 53,0 | 8,0 | 12,0 | 16,0 |

| SEPGRA-MK4C | 13 | 5.100 | 102 | 510 | 340 | 120 | 320 | 205 | 60,0 | 10,0 | 14,0 | 19,0 |

The data reported is purely indicative

Static Degreaser / Grease Separator Aerated with Enzymes

for Manufacturing Activities, Bakeries, Meal preparation centers

Supply specifications

Supply and Installation of a Degreaser / Grease Separator, Aerated with Enzymes, to be installed underground, manufactured in DECLARED SERIES Mod. DEGAENZ____ , outer dimensions cm.____X____Xh____ , effective volume _____ lt., manufactured by EDIL IMPIANTI 2 S.r.l. with UNI EN ISO 9001 and ISO 45001 management system made of monoblock vibrated concrete, reinforced with vertical pillars and stainless steel horizontal beams, with CE-certified materials, concrete in compressive strength class C45/55 (RCK >55 N/mm²), internal improved-adhesion steel reinforcements checked in our plant, GREESMIX5® steel fibers (patent No. 0001421398 issued by the Ministry for Economic Development) and electro-welded square mesh B450C, with certification of CHEMICAL RESISTANCE and REACTION TO FIRE (Class A1) issued by an external body based on UNI EN standards.

The Degreaser/Grease Separator Aerated with Enzymes, external dimensions.____X____X h____ , effective volume _____ lt., the system is equipped with:

PVC connections in input/output, imprints/vents/holes placed/i laterally to the entrance hole, septa in c.a.v. for the formation of various compartments, ventilation compartment/ equalization, aeration with microbubble diffusers in epdm, side channel blower 230/ 400v, KITDOSAG_100: Dosing kit consisting of digital dosing pump type SMM-220-02 AAE operating mode controlled by microprocessor, constant flow rate with manual adjustment and three-digit digital display for control adjustment from 0 to 100%, body tested pp, ptfe membrane, fpm lip valve, lt/h flow rate 2, max pressure 20 bar, PVC suction lance with filter and probe level 60 cm (tank excluded from this item), electrical panel, visual acoustic alarm, packaging of enzymes to be diluted on ns. specification (on request).

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

Static Degreaser / Grease Separator - Aerated with enzymes Measurements

| Article Code |

Usable Volume (lt) |

Degreaser Aerated with enzymes | Technical Compartment (cm.) | |||||||

| External Dimensions (cm) | Tank Weight (ql) |

Cover slab weight (ql) | External Dimensions (cm) |

Weight (ql) | ||||||

| Width | Length | Height | h. 10 cm (B125) |

h. 15 cm (C250) |

h. 20 cm (D400) |

|||||

| DEGAENZ12A | 10.000 | 180 | 420 | 200 | 108,6 | 18,8 | 28,2 | 37,6 | 125x110xH130 | 12,0 |

| DEGAENZ12B | 11.500 | 180 | 470 | 200 | 117,1 | 21,0 | 31,5 | 42,0 | 125x110xH130 | 12,0 |

| DEGAENZ13A | 12.500 | 180 | 520 | 200 | 125,5 | 23,3 | 34,9 | 46,5 | 125x110xH130 | 12,0 |

| DEGAENZ13B | 14.000 | 180 | 570 | 200 | 134,0 | 25,5 | 38,2 | 51,0 | 125x110xH130 | 12,0 |

| DEGAENZ16B | 14.000 | 246 | 420 | 200 | 137,0 | 25,7 | 38,5 | 51,3 | 125x110xH130 | 12,0 |

| DEGAENZ17B | 16.000 | 246 | 470 | 200 | 151,1 | 28,7 | 43,1 | 57,4 | 125x110xH130 | 12,0 |

| DEGAENZ18B | 18.000 | 246 | 520 | 200 | 161,0 | 31,8 | 47,7 | 63,6 | 125x110xH130 | 12,0 |

| DEGAENZ19B | 20.000 | 246 | 570 | 200 | 170,9 | 34,8 | 52,2 | 69,7 | 125x110xH130 | 12,0 |

The data reported is purely indicative

For bigger capacities, please contact our technical department