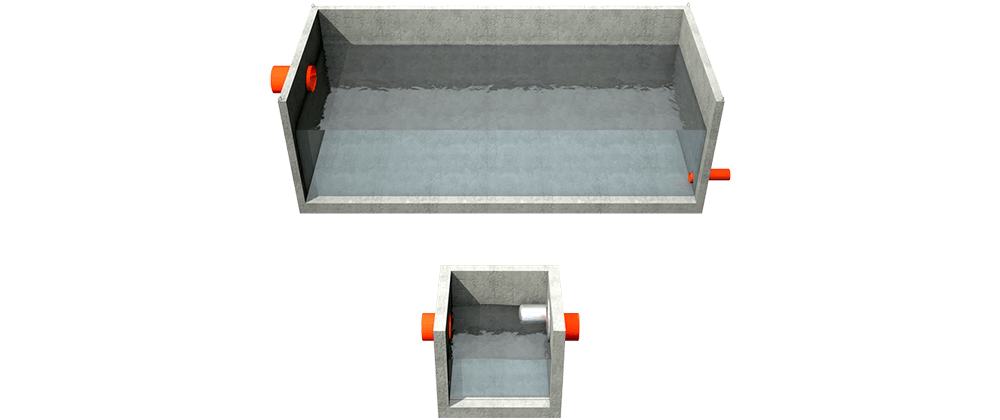

Precast reinforced concrete monoblock

with Flow Regulator or Limiter

Manhole with Calibrated Orifice

Hydraulic Invariance Tank Features

Due to urbanization, large portions of vegetated territories with permeable surfaces have been replaced by impermeable surfaces.

Definition of Hydraulic Invariance and Hydrological Invariance, compared to the pre-urbanization situation:

Hydraulic Invariance is defined as the Peak flow invariance

Hydrological Invariance is defined as the Flood volume invariance.

Objective of the intervention strategies:

achieving Hydraulic Invariance and possibly Hydrological Invariance as well;

controlling water quality by reducing its pollutant content.

Lamination basins act as hydraulic buffers during meteorological events of particular intensity and duration, temporarily holding and storing (based on sizing) the flow and volumes intercepted by impermeable surfaces, thus avoiding dangerous overloads to the final receptors (sewers, surface water bodies, and/or soil);

Lamination tanks can include the following accessories \ components:

System with "throttled" outlet or calibrated weir;

Flow regulator from 3 to 100 l/s made of stainless steel to be installed inside the lamination basin or in a specific structure downstream of the outlet, capable of ensuring a constant discharge to the receptor regardless of the water head inside the storage;

It frequently happens that the final discharge of the accumulated water occurs by gravity, through pipes with free-surface discharge outlets with a smaller diameter than the inlet pipe (VLL). Otherwise, it can occur through pipes with variable-surface discharge outlets using flow control valves with float control or hydraulic vortex outlets (cyclone, vertical or horizontal centrifuge) (VLV).

Alternatively, in other situations, the final discharge can take place through the use of submersible electric pumps installed inside the tanks and appropriately sized, controlled by electrical panels capable of ensuring the design flow at the discharge point (VLP).

Lamination / Hydraulic Invariance Tanks are complete with:

- Watertight PVC couplings inserted into the tank walls for inlet and discharge pipe connection (VLL).

- AISI 304/316 stainless steel flow control valves with CE marking (VLV);

- Submersible discharge electric pumps equipped with an electrical control panel (VLP).

Flow Limitation or Regulation System

Used to limit the flow rate and regulate a constant discharge into sewer collectors, reinforced concrete structures, overflow tanks or manholes, lamination basins, storage tanks, and first flush treatment systems; this is a mechanical regulation system that does not use electromechanical parts and therefore requires no electrical energy.

It allows for a constant discharge flow rate both when the tank is empty and during the increase in water level during high-intensity rainfall events.

Construction materials

The product is constructed entirely of AISI 304 stainless steel.

Operation

The weir that regulates the flow and the calibrated orifice is mounted on a box connected to the outlet piping and is opened or closed based on the position of a rod and a float to which it is connected. No adjustments are necessary as the system is already installed in the tank at the factory and calibrated according to the inlet/outlet piping.

Adjustment and maintenance

The system is designed and sized to require no routine maintenance or adjustment following installation.

Supply Specifications

Supply and installation of an Stormwater Attenuation / Hydraulic Invariance Tank with a reduced diameter outlet, produced in DECLARED SERIES, code VACM______ or with nominal wall thickness of cm.10/15/20, code VACM______ S10/S15/S20, with external dimensions of cm.x___xh for mc.___ with a wall thickness of cm.__ and a bottom thickness of cm.__, manufactured by EDIL IMPIANTI 2 S.r.l. with a UNI EN ISO 9001 and ISO 45001 management system, made of monoblock Vibrated Reinforced Concrete, reinforced with vertical pillars and horizontal stainless steel struts, with a protective anti-cracking elastomeric paint Elastocolor on the external concrete walls for high permanent elasticity and high chemical resistance, concrete in compression resistance class C45/55 (RCK >55 N/mm²), internal reinforcement in improved adhesion steel controlled in the factory and B450C square-mesh welded wire fabric, complete with CHEMICAL RESISTANCE and REACTION TO FIRE (class: A1) certifications issued by an external body according to UNI EN standards.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

Stormwater attenuation tank / Hydraulic Invariance Dimensions

To view the product dimensions, please refer to the measurements of the Precast Concrete Tank and its Extensions and Cover Slabs.