First Rainwater Tanks for Stormwater Treatment

First Rainwater Systems in continuous for large Areas

Features and Operating Principle

First Rainwater Systems for large Areas are designed and sized according to UNI EN 858-1 standards for discharges into public sewers or surface waters, limited to floating substances and settleable solids. Their use controls the conveyance of rainwater into sewage networks, promoting on-site disposal.

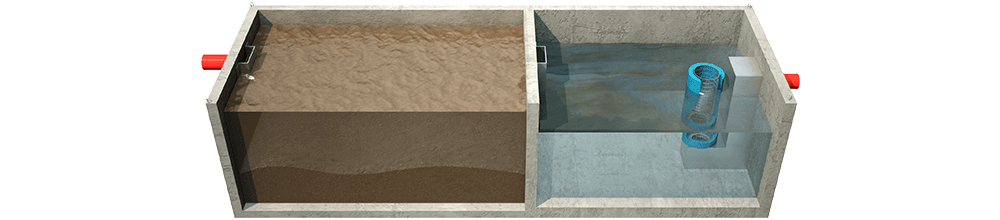

The system includes two distinct basins: a grit trap (desanding) and an oil separator equipped with a discharge device featuring a Stainless Steel float shutter and a Coalescence Filter.

Operation of First Rainwater Systems for large Areas

The pollution produced by rainwater runoff is essentially due to the presence of sand, silt, and non-emulsified light mineral oils.

Surfaces affected by precipitation must be appropriately prepared to facilitate the conveyance of first flush water to a single point where the grit trap will be positioned.

The first flush water begins treatment in the desanding section for a suitable time to allow the separation of settleable substances.

The pre-treated water is then sent to the oil removal section, where light substances undergo flotation. For wastewater that must meet the acceptability limits set by Legislative Decree No. 152/06 for discharge into surface waters, a coalescence filter is used.

With this system, oil micro-particles adhere to a specific coalescing material (absorption effect) and, after merging together, increase in size (coalescence effect) to facilitate their flotation to the surface.

The oil separator discharge is automatically closed by a Stainless Steel float shutter to prevent oil leakage when it reaches a specific level in the collection chamber.

Supply Specifications

Supply and installation of a First Flush Rainwater System for Large Surfaces manufactured in DECLARED SERIES, code GRIMP-FC____, flow rate ___ lt./sec., pipe diameter DN___, consisting of Prefabricated Underground Tanks produced by EDIL IMPIANTI 2 S.r.l. with a UNI EN ISO 9001 and ISO 45001 management system, made of monobloc Vibrated Reinforced Concrete, reinforced with vertical pillars and horizontal braces in stainless steel, with Elastocolor protective anti-cracking elastomeric paint on the external concrete walls for high permanent elasticity and high chemical resistance, concrete in compression strength class C45/55 (RCK >55 N/mm²), internal reinforcement in improved-adhesion steel controlled at the factory and B450C type square-mesh electro-welded wire mesh, complete with certifications for CHEMICAL RESISTANCE and REACTION TO FIRE (class: A1) issued by an external body according to UNI EN standards.

The First Flush Rainwater System for Large Surfaces, manufactured in DECLARED SERIES, code GRIMP-FC____, consists of:

- Grit chamber consisting of no. _ tank/tanks with external dimensions of cm.____x____xh____, complete with inlet/outlet holes and an AISI 304 stainless steel baffle at the inlet;

- Oil separator consisting of no. _ tank/tanks in compliance with the UNI EN 858-1 standard with external dimensions of cm.____x____xh____, complete with inlet/outlet holes, an AISI 304 stainless steel baffle at the inlet, a Refill coalescence filter in an AISI 304 stainless steel frame that is removable and washable, and an automatic shut-off device of the float-shutter type, made entirely of AISI 304 stainless steel.

Treatment Guarantee:

D.Lgs.152/06 Part three, Annex 5, Table 3 "Discharge into Surface Waters," provided that the qualitative and dimensional values of the inflow into the treatment itself are respected and guaranteed, limited to the parameters of total suspended solids and total hydrocarbons.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

Fields of Application

First Rainwater Systems for large Areas are used to treat water coming from roads, highways, transit zones, service station forecourts, parking lots, and/or car demolition yards. This water is primarily polluted by involuntary leaks from parked vehicles containing mineral oils, sand, and soil.

Regulation

Emilia Romagna Regulation DR 1860/2006. The regulation requires that first flush rainwater and wash water from external areas be conveyed and appropriately treated in purification plants for specific cases where, in relation to the activities performed, there is a risk of hazardous substances or pollutants being washed off uncovered impermeable surfaces, potentially compromising the quality objectives of water bodies.

First flush systems for large surfaces are designed in accordance with Lombardy Regional Law No. 62 Art. 19/20 of May 27, 1985, and subsequent amendments. Regional Council Resolution of June 21, 2006, No. 8/772, directive for the assessment of second flush water pollution in implementation of Art. 14, paragraph 2 R.R. No. 4 2006.

First Rainwater Systems in continuous for large Areas Dimensions

Download Technical Drawings

Select Article Code to access the Data Sheet for the product.

| Article Code |

Range (lt/sec) |

Pipes Diam. (mm) |

Static Desander N. |

Desander | Oil Skimmer Sperator N. |

Oil Separator | Coalescence filter N. |

||||||||||

| External Dimensions (cm) |

Weight (ql) |

Cover slab weight (ql) |

External Dimensions (cm) |

Weight (ql) |

Cover slab weight (ql) |

||||||||||||

| Width | Length | Height | h. 15 cm (C250) |

h. 20 cm (D400) |

Width | Length | Height | h. 15 cm (C250) |

h. 20 cm (D400) |

||||||||

| GRIMP-FC/100 | 100 | 400 | 1 | 246 | 570 | 250 | 163,9 | 52,2 | 69,7 | 1 | 246 | 420 | 250 | 124,9 | 38,5 | 51,3 | 1 |

| GRIMP-FC/150 | 150 | 400 | 1 | 246 | 670 | 250 | 186,2 | 61,4 * | 81,9 * | 1 | 246 | 420 | 250 | 124,9 | 38,5 | 51,3 | 1 |

| GRIMP-FC/200 | 200 | 400 | 1 | 246 | 770 | 250 | 214,0 | 70,6 * | 94,1 * | 1 | 246 | 470 | 250 | 141,5 | 43,1 | 57,4 | 1 |

| GRIMP-FC/300 | 300 | 400 | 2 | 2x246 | 2x670 | 2x250 | 2x186,2 | 2x61,4 * | 2x81,9 * | 2 | 2x246 | 2x420 | 2x250 | 2x124,9 | 2x38,5 | 2x51,3 | 2 |

| GRIMP-FC/400 | 400 | 400 | 2 | 2x246 | 2x770 | 2x250 | 2x214,0 | 2x70,6 * | 2x94,1 * | 2 | 2x246 | 2x470 | 2x250 | 2x141,5 | 2x43,1 | 2x57,4 | 2 |

* Cover Slab divided into two parts - The data reported is purely indicative

It is possible to have extensions (bottomless tanks) for all of our products