Industrial Wastewater Treatment

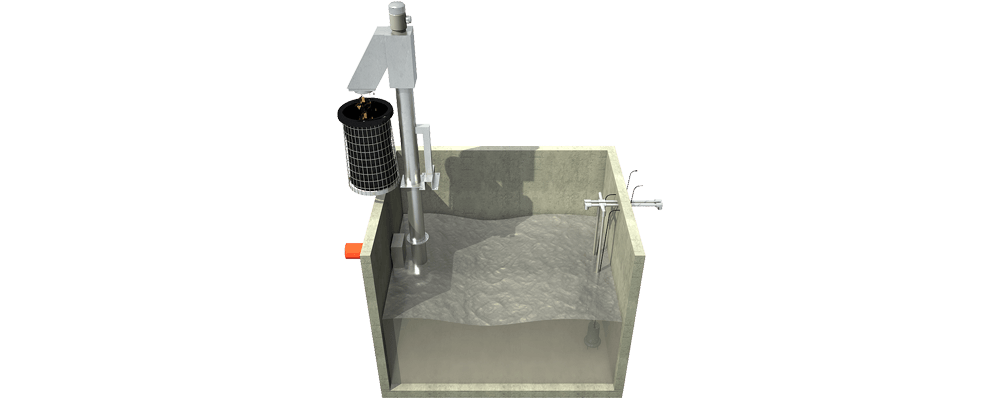

Grilling with Screw Filter

Inclined to be installed in precast reinforced concrete channel or Vertical to be installed in precast reinforced concrete tank.

Introduction

Screening is one of the first operations that must be included upstream of a civil or industrial wastewater treatment plant. Its purpose is to intercept and separate suspended particulate solids before they damage or slow down the subsequent purification processes. The Filter-Screw with compactor is specifically designed for the fine screening of influent sewage or in the most varied industrial applications; it is generally installed downstream of a coarse screen. The degree of filtration is chosen based on the type and quantity of material expected and according to the purification process scheme adopted. Thanks to the filtering screen, consisting of a semi-cylindrical sieve, this machine is able to block the smallest bodies (larger than the filtration mesh/opening) in suspension and, by means of a screw conveyor, lift them out of the water flow, compact them and convey them to the discharge, located in the upper part of the machine.

operating Principle

The process starts with the perforated basket which retains only the solids, allowing the liquid to pass through. The inner part of the screen is continuously cleaned by brushes fixed to the external diameter of the spiral. The shaftless screw conveys the material upwards towards the compaction zone where the material is further dewatered. A volume reduction of the material of up to more than 35% of the original volume can be achieved. During lifting, the screened material undergoes washing in order to remove soluble organic substances.

Regulations

Legislative Decree (D.L.) 152/06 and Emilia Romagna Regional Council Resolution 1053/2003: Discharge of domestic wastewater not connected to the public sewer system; discharge into surface water.

Features

The Filter-Screw for the fine screening of civil and/or industrial wastewater comes in two types: inclined, to be installed in a precast reinforced concrete channel or in a steel container; or vertical, to be installed in a precast reinforced concrete tank. The Filter-Screw also integrates the functions of screening, washing, and compaction of the screened material. The Filter-Screw is mainly composed of a shaftless rotating screw, driven by a gearmotor, which is placed inside the filter and cleans the holes of the filter using low-wear plastic brushes and a washing bar equipped with spray nozzles. In the final stage of the machine, the residue is dewatered in the compaction zone and conveyed to the discharge outlet. The Filter-Screw has the capability for continuous plastic bag discharge. The inclined and/or vertical Filter-Screw is constructed from AISI 304 stainless steel, while the spiral (or flight) is constructed from thick carbon steel. Accessories: quick coupling foot (vertical type only); support foot (both inclined and vertical types). Optional Accessories: washing device for the compaction zone and screen 1 lt/s at 2.5 and 5 bar; electrical control panel; precast reinforced concrete channel or steel container; precast reinforced concrete tank. Technical Specifications: models available for flow rates from 20 to 700 m³/h; circular holes 3 to 7 mm; inclination 35° or vertical; oil-bath gearmotor; power 0.75 to 1.1 kW; shaftless spirals (flights); volume reduction of solids up to 35%; absence of internal supports; shaftless spiral prevents jamming or blockages, even with fibrous materials; long-life brushes. The degree of filtration can be distinguished into two types: coarse filtration degree with holes from 3 to 5 mm; fine filtration degree with trapezoidal bars from 1.50 to 0.20 mm. (* Coanda effect). * is the tendency of a fluid jet to follow the contour of a nearby surface.

Fields of Application

Civil plants, slaughterhouses, cured meat factories, wineries, dairies, food industries, canning industries, pasta factories, confectionery products, fish industries, laundries and dry cleaners, residential buildings, condominiums, restaurants, hotels, hospitals, communities, canteens, catering services, schools, bars, campsites, bathing establishments, motorway service areas, meal production centers.