Industrial Wastewater Treatment

Car Wash treatment Systems

Introduction

For years, car wash stations (self-service or manned) have been present on the market. These facilities use specific products for cleaning exterior surfaces, excluding the engine compartment; the wastewater resulting from this process cannot be discharged directly into the public sewer system or into surface water bodies, in compliance with Legislative Decree 152/06 and subsequent amendments/additions.

Therefore, this water must be treated using a suitable purification plant: for this purpose, EDIL IMPIANTI2 has developed a biological system (biofiltration reactor) capable of achieving high removal rates of the pollution generated by car wash activities.

Operating Principle

Wastewater from primary treatments such as sand removal and oil separation (sand trap or sludge separator and oil removal or oil separator) passes through the plastic inert packing material within the structure with an upward flow in co-current with the air. All organic substances present in the car wash wastewater settle on the filling media, where they are attacked by aerobic bacteria that initiate the biological degradation process. Briefly, the biological oxidation process consists of bringing the wastewater from washing activities (cars, trucks, buses, etc.) into contact with a proportionate amount of oxygen blown into the tank by a side-channel blower. A series of perforated pipes placed on the bottom ensure the necessary oxygen supply to the water. In this specific compartment of the purification plant, microorganisms develop spontaneously, reproducing, living, and growing. In this bacterial bed, the conditions governing the natural phenomenon of self-purification—driven by the presence of aerobic microorganisms (as occurs in surface water bodies)—are developed in an artificial and accelerated manner, utilizing the organic matter present in the water and transforming it into activated sludge.

Regulation

Legislative Decree no. 152 of May 11, 1999, Provisions on the protection of water from pollution and transposition of Directive 91/271/EEC concerning urban wastewater treatment.

(Published in the Ordinary Supplement no. 101/L to the Official Gazette no. 124 of May 29, 1999).

Updated with the amendments of Legislative Decree no. 152 of April 3, 2006, laying down provisions on the protection of water from pollution.

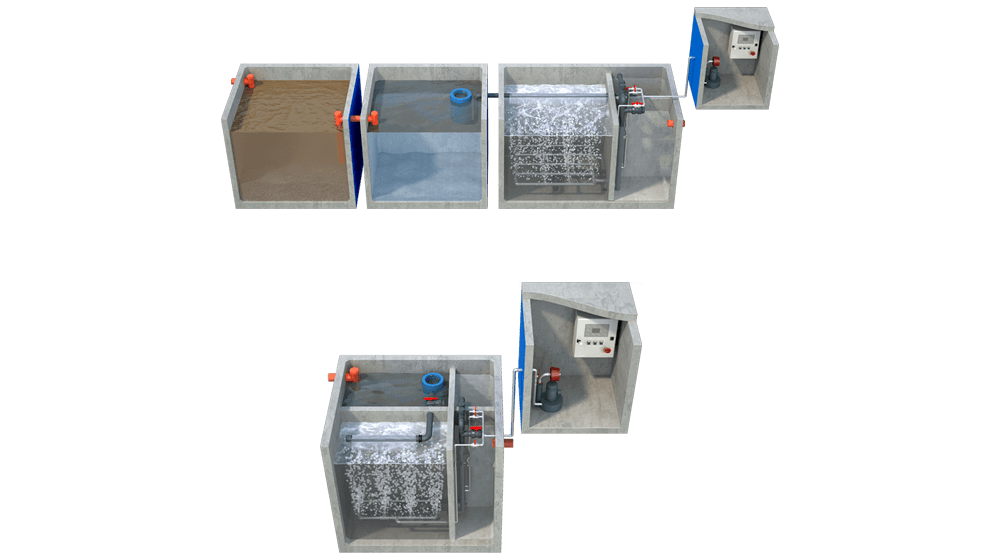

Modular Car Wash treatment Systems

Supply Specifications

Supply and installation of a Modular Car Wash treatment Systems produced in DECLARED SERIES code SBAF__MOD for discharges into surface waters, composed of Prefabricated Buried Tanks produced by EDIL IMPIANTI 2 S.r.l. with a UNI EN ISO 9001 and ISO 45001 management system, made of monoblock Vibrated Reinforced Concrete, reinforced with vertical pillars and horizontal stainless steel struts, with Elastocolor protective anti-cracking elastomeric paint on the external concrete walls with high permanent elasticity and high chemical resistance, concrete in compression resistance class C45/55 (RCK >55 N/mm²), internal steel reinforcements with improved adherence controlled at the factory and B450C type square-mesh electro-welded wire mesh, accompanied by CHEMICAL RESISTANCE and REACTION TO FIRE (class: A1) certificates issued by an external body according to UNI EN standards.

The Modular Car Wash Purifier is composed of 6 compartments: Sand Separator, Oil Separator, Biofiltration Reactor, Sludge Accumulation, Clarified Water Accumulation, and Technical Compartment.

The various phases (sand separation, oil separation, biofiltration, sludge accumulation, clarified water accumulation) are in turn supplied complete with: inlet/outlet holes, phase connection pipes, ringed PVC fittings, Refill type coalescence filtration, 90mm diameter PVC channel complete with PVC ball valve, lower and upper grid for closing the filling bodies, spherical bulk filling bodies in isotactic polypropylene with a specific surface area of approximately 450-550 sq.m./cu.m., air delivery manifold, 40mm diameter perforated PVC pipes with PVC ball valve, no. 2 Air-lifts in 63mm diameter PVC each complete with 20mm diameter PVC air delivery pipe, 20mm diameter PVC ball valve, 90mm diameter clarified discharge PVC pipe with PVC ball valve, stainless steel and PVC brackets/collars for fixing pipes.

The Technical Compartment is supplied complete with: AISI 304 stainless steel door with lock, no.2 ventilation grilles, light point (on request), no.2 holes, no.1 side channel blower, 200 mbar pressure, complete with filter, silencer, anti-vibration hose and electrical panel with PLC logic in polycarbonate complete with accessories for automatic blower control, contactor, thermal protection relay, pause-work programmer, man-0-aut selector, block and operation indicator lights.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

Modular Car Wash treatment Systems Dimensions

for discharge into surface water

Download Technical Drawings

Select Article Code to access the Data Sheet for the product.

| Article Code |

Flow Rate Q (mc/h) |

Desander | Oil Separator | Monoblock Biofiltration Unit ** | Technical Compartment | |||||||

| External Dimensions (cm) |

Weight (ql) |

Weight of Cover Slab (ql) |

External Dimensions (cm) |

Weight (ql) |

Weight of Cover Slab (ql) |

External Dimensions (cm) |

Weight (ql) |

Weight of Cover Slab (ql) |

External Dimensions (cm) |

Weight (ql) |

||

| h. 20 cm (D400) |

h. 20 cm (D400) |

h. 20 cm (D400) |

||||||||||

| SBAF01MOD | 1,0 | 180x125xH200 | 35,7 | 11,2 | 180x125xH200 | 35,7 | 11,2 | 180x180xH200 | 57,0 | 16,1 | 125x110xH130 | 12,0 |

| SBAF02MOD | 2,0 | 180x180xH200 | 47,6 | 16,1 | 180x180xH200 | 47,6 | 16,1 | 180x270xH200 | 73,8 | 24,1 | 125x110xH130 | 12,0 |

| SBAF03MOD | 3,0 | 180x220xH200 | 54,3 | 19,7 | 180x220xH200 | 54,3 | 19,7 | 180x320xH200 | 82,1 | 28,6 | 125x110xH130 | 12,0 |

** Monoblock Biofiltration Unit: Biofiltration Reactor/Sludge Accumulation/Clarified Water Accumulation

The data reported is purely indicative

Compact Car Wash treatment Systems

Supply Specifications

Supply and installation of a Compact Car Wash treatment Systems produced in DECLARED SERIES code SBAF__COMP for discharges into surface waters, composed of a Prefabricated Buried Tank produced by EDIL IMPIANTI 2 S.r.l. with a UNI EN ISO 9001 and ISO 45001 management system, made of monoblock Vibrated Reinforced Concrete, reinforced with vertical pillars and horizontal stainless steel struts, with Elastocolor protective anti-cracking elastomeric paint on the external concrete walls with high permanent elasticity and high chemical resistance, concrete in compression resistance class C45/55 (RCK >55 N/mm²), internal steel reinforcements with improved adherence controlled at the factory and B450C type square-mesh electro-welded wire mesh, accompanied by CHEMICAL RESISTANCE and REACTION TO FIRE (class: A1) certificates issued by an external body according to UNI EN standards.

The Compact Car Wash Purifier is composed of 6 compartments: Sand Separator, Oil Separator, Biofiltration Reactor, Sludge Accumulation, Clarified Water Accumulation, and Technical Compartment.

The various phases (sand separation, oil separation, biofiltration, sludge accumulation, clarified water accumulation) are in turn supplied complete with: inlet/outlet holes, phase connection pipes, ringed PVC fittings, Refill type coalescence filtration, 90mm diameter PVC channel complete with PVC ball valve, lower and upper grid for closing the filling bodies, spherical bulk filling bodies in isotactic polypropylene with a specific surface area of approximately 450-550 sq.m./cu.m., air delivery manifold, 40mm diameter perforated PVC pipes with PVC ball valve, no. 2 Air-lifts in 63mm diameter PVC each complete with 20mm diameter PVC air delivery pipe, 20mm diameter PVC ball valve, 90mm diameter clarified discharge PVC pipe with PVC ball valve, stainless steel and PVC brackets/collars for fixing pipes.

The Technical Compartment is supplied complete with: AISI 304 stainless steel door with lock, no.2 ventilation grilles, light point (on request), no.2 holes, no.1 side channel blower, 200 mbar pressure, complete with filter, silencer, anti-vibration hose and electrical panel with PLC logic in polycarbonate complete with accessories for automatic blower control, contactor, thermal protection relay, pause-work programmer, man-0-aut selector, block and operation indicator lights.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

Compact Car Wash treatment Systems Dimensions

for discharge into surface water

Download Technical Drawings

Select Article Code to access the Data Sheet for the product.

| Article Code |

Flow Rate Q (mc/h) |

Compact Monoblock System ** | Technical Compartment | |||

| External Dimensions (cm) |

Weight (ql) | Cover Slab Weight (ql) |

External Dimensions (cm) |

Weight (ql) | ||

| h. 20 cm (D400) |

||||||

| SBAF01COMP | 1,0 | 180x220xH200 | 66,2 | 19,7 | 125x110xH130 | 12,0 |

| SBAF02COMP | 2,0 | 180x420xH200 | 106,7 | 37,6 | 125x110xH130 | 12,0 |

| SBAF03COMP | 3,0 | 180x470xH200 | 115,3 | 42,0 | 125x110xH130 | 12,0 |

** Compact Monoblock Plant: Sand Filter/Oil Separator/Biofiltration Reactor/Sludge Accumulation/Clarified Water Accumulation

The data reported is purely indicative