Rectangular Imhoff Pit - CE marking, reference standard: UNI EN 12566-1

Imhoff Pit dimensions: 185 - 200 - 250 lt P.E.

Operating Features and Dimensions

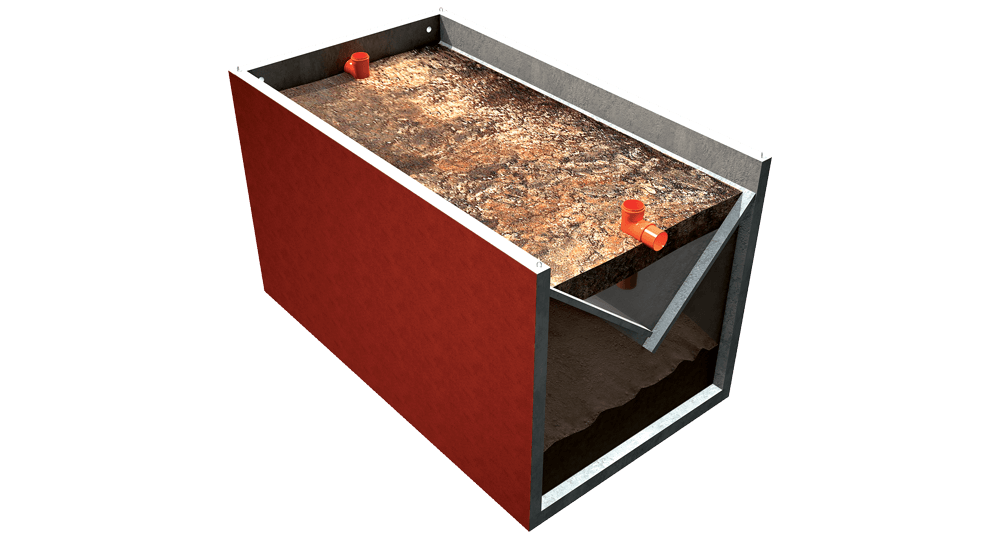

Precast concrete underground Imhoff Tanks (also called Imhoff Pits) with different dimensions, are the very first primary purification step for wastewater, based on the applicable law: they are compulsory in the whole national territory.

Imhoff Tanks are septic tanks made up of two compartments: an upper sedimentation compartment and a lower digestion compartment. The slurry gets into the sedimentation compartment, where settleable suspended solids fall along the inclined hopper walls into the collection compartment underneath and then into the digestion compartment through the longitudinal communication slot.

What's the purpose to an Imhoff Tank? Suspended particles accumulate in Imhoff Tanks and make up for a thick crust, which, must be removed on a regular basis - 1 to 4 times a year. After a specific retention time, water get clarified, as it has had no contact with the compartment underneath. The material accumulated on the tank bottom is digested by anaerobic bacteria, biological gas produced during fermentation are released through the side vents next to the inlet openings, which must be connected to pipes leading to the roof.

It is important to perform a pre-emptive abatement (degreaser-grease separator) before treating wastewater Imhoff tanks, as oils, fats and detergents can cause serious inconvenience during the different treatment phases. For correct tank functioning it is necessary to avoid introducing thick items of any kind, such as: plastic bags, nappies, sanitary towels/tampons, cotton swabs, etc.

The structure of the Imhoff tank must be thoroughly checked, with or without aquifer.

The advantages to the monoblock system:

- if compared to septic tanks made of concrete rings, installation time is much shorter, as there are no joints to be sealed, as the tank is made of just one casting.

Other positive aspects to monolithic tanks in vibrated reinforced concrete against plastic tanks:

- Installation time is very short, as no filling with water is required, nor other action is required for backfilling;

- they are carriageable and resist average, heavy and first category traffic;

- they are self-supporting structures against the ground pressure outside and, therefore, are not subject to crushing during maintenance/draining operations.

More information also from the website: https://www.fosseimhoff.it/

Supply Specifications

Supply and installation of Underground Imhoff Tank, CE marked by external notified body No. 0407, produced in DECLARED SERIES, code IMHOFF______ or IMHOFF-MK__ (Miniblock version), compliant with UNI EN 12566-1 standard, with external dimensions of ____x____xh___ cm, for ____ P.E. with 185 liters, for ____ P.E. with 200 liters, for ____ P.E. with 250 liters, produced with UNI EN ISO 9001 and ISO 45001 management systems, made of monobloc reinforced concrete (R.C.) with CE certified materials and recycled content according to the requirements indicated in the Minimum Environmental Criteria (CAM), concrete compressive strength class C45/55 (RCK >55 N/mm²), compliant with the provisions of UNI EN 206-1 and UNI 11104 for exposure classes XC4, XS3-XD3, XF1, XA2, internal reinforcement with high-bond steel, GREESMIX5® steel fibers (if provided), IDROCONCRETE 1200® crystallizing additive for integral waterproof concrete (if provided), accompanied by Chemical Resistance and Reaction to Fire certifications issued by an external body according to UNI EN standards, reinforced with vertical R.C. columns and stainless steel horizontal struts where provided, with Elastocolor protective anti-crack elastomeric painting of the external concrete walls with permanent high elasticity and high chemical resistance.

The CE marked Imhoff Tank is supplied complete with:

inlet/outlet indentations/drilling; air vent indentations/holes placed laterally to the inlet hole; internal hoppers made of reinforced concrete or AISI 304 stainless steel (provided exclusively on certain sizes).

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

Applicable Regulation

UNI EN 12566-1 small wastewater treatment systems up to 50 PE Part 1: precast septic tanks.

The Imhoff tanks must be compliant with the UNI EN 12566-1 standard.

Resolution of the Interministerial Committee for water protection No. 48/77, Legislative Decree Law No. 152/06, Regional Resolution of the Emilia-Romagna Region n. 1053/03, Regional Resolution of the Umbria Region 1171/07, D.A.C.R. Resolution. No. 145/10 Marche Regional Water Protection Plan, Decree of the President of the Autonomous Region of Bolzano No. 6/08.

Imhoff tanks have a primary sedimentation purification performance.

Purification performance table:

- bod-cod (25- 35 %)

- settleable suspended solids (from 85 - 90%)

- total suspended solids (from 55 - 65%)

Dimensions

Dimensions to calculate Population Equivalent

Let us make an example, to try and calculate the dimensions of an Imhoff tank for 20 people. Is the definition "people" correct? Not exactly. It is more appropriate to state you want to define the dimensions for an Imhoff tank for 20 Population Equivalent.

In residential housing as well as in manufacturing or service companies, it would be necessary to assess the effective sludge production to be disposed of to find the right system dimensions. Since this is almost impossible, it is necessary to refer to the Population Equivalent (P. E.), i.e., a standardized measurement unit, which can be determined as follows.

Concrete Imhoff Tank dimensions for:

Civil Residence - counting beds: 1 P.

- 1 P. E. for bedrooms with up to 13.90 sqm surface

- 2 P. E. for bedrooms with over 14 sqm surface

Hotel or accommodation structure - the same as for civil residence;

add 1 P. E. every time the room surface has a 6 sqm increase over 14 sqm;

for vacation structures or special situations where the seasonal use causes strong population density, it is necessary to consider the maximum effective potential of the structure.

Factories or artisan workshops - 1 P. E. every 2 employees - permanent and seasonal - during most intense activity times.

Companies, Commercial Offices, stores - 1 A. E. every 3 employees - permanent and seasonal - during most intense activity times.

Restaurants - to calculate the population equivalent, it is necessary to estimate the maximum accommodation capacity of the dining rooms, considering that a person takes around 1.20 sqm, together with the guests, you have to count the staff as well. 1 P.E. every 3 people.

Cafés and Clubs - as under the previous point but calculating 1 P. E. every 7 people.

Cinemas Stadiums Theatres - every 30 users corresponding to 1 P. E.

Schools and Gyms - every 10 people calculated based on maximum potential corresponding to 1 P.E.

Specific cases must be assessed individually, please contact our technical department.

Note

After calculating the Population Equivalent, it is necessary to contact the local authorities (A.R.P.A., Province, HERA) to define which kind of systems should be installed.

The water supply to be calculated can range from 100 lt to 250 lt for every Population Equivalent, depending on local regulation and the activity carried out.

Fields of application

Imhoff tanks are monoblock reinforced concrete tanks

and they are used to treat wastewater, more specifically for housing, hotels, restaurants, hospitals, tourist centers, small towns, small and medium sized water treatment systems located before lifting stations.

Civil residence systems, slaughterhouses, wine cellars, cheese factories, food industry, conservation industry, pasta manufacturers, pastry manufacturers, fish industry, laundry services, civil residence, blocks, restaurants, hotels, hospitals, communities, canteens, catering services, schools, bars, camping sites, bathing establishments, service stations, meal production centers.

More information

Imhoff tanks are also called septic tanks and stand for an example of compact combined system for water treatment. The typical configuration designed and patented in 1904 is composed of 2 separated but connected compartments: an upper settling compartment and a lower collections and anaerobic digestion compartment (with no oxygen) for settled sludge.

Settleable suspended solids in wastewater collected in the upper settling compartment fall through a slot connecting both compartments down into the lower compartment, where organic materials are subject to anaerobic fermentation and subsequent stabilization.

Imhoff tanks differ from septic tanks due to the separation between upper and lower digestion compartment, which makes it possible to obtain a "fresh" final outflow on the one hand (as it is retained in the settling compartment for a short time) and to digest sludge in the lower compartment in a uniform and controlled manner on the other.

Imhoff tanks treatment performance is equivalent to primary settling tank performance (BOD5 and COD, about 25-35%) - (settleable SS around 85-90%) - total SS about 55-65%).

The production of digested sludge of Imhoff tanks only used for primary treatment ranges from 0.3 and 0.6 l/P.E. a day, with a SS unitary input of about 35 g/P.E. a day. Of course, the input is bigger if the Imhoff tank also collects waste activated sludge coming from secondary treatments placed after the tank itself.

As for septic tanks, sludge must be regularly collected with specific means/ by specialized companies and disposed of in accordance with the law in specific treatment plants.

We always recommend leaving some sludge in the Imhoff tank when collecting it.

Imhoff Tanks Dimensions

Download Technical Drawings

Select Article Code to access the Data Sheet for the product.

| Article Code |

Dimensions with lt. for P.E. |

Usable Volume (Sed.+Dig.) (lt) |

External Dimensions Imhoff Tank (cm) |

Tank Weight (ql) |

Cover slab weight (ql) | ||||||

| lt.185 for P.E. | lt.200 for P.E. | lt.250 for P.E. | Width | Length | Height | h. 10 cm (B125) |

h. 15 cm (C250) |

h. 20 cm (D400) |

|||

| IMHOFF1000 | 4 | 4 | 3 | 850 | 125 | 130 | 100 | 13,4 | 4,0 | 6,1 | 8,1 |

| IMHOFF-MK1A | 5 | 5 | 4 | 1.050 | 120 | 170 | 100 | 22,0 | 5,0 | 8,0 | 10,0 |

| IMHOFF-MK2A | 7 | 6 | 5 | 1.300 | 120 | 220 | 100 | 27,0 | 7,0 | 10,0 | 13,0 |

| IMHOFF2000AB | 7 | 6 | 5 | 1.300 | 125 | 180 | 100 | 17,2 | 5,6 | 8,4 | 11,2 |

| IMHOFF-MK3A | 8 | 8 | 6 | 1.600 | 120 | 270 | 100 | 32,0 | 8,0 | 12,0 | 16,0 |

| IMHOFF2000AA | 9 | 9 | 7 | 1.800 | 175 | 180 | 100 | 21,8 | 7,8 | 11,7 | 15,6 |

| IMHOFF-MK4A | 10 | 10 | 8 | 2.000 | 120 | 320 | 100 | 37,0 | 10,0 | 14,0 | 19,0 |

| IMHOFF2000 | 10 | 10 | 8 | 2.000 | 180 | 220 | 100 | 38,4 | 9,8 | 14,8 | 19,7 |

| IMHOFF3000B | 13 | 12 | 10 | 2.500 | 180 | 270 | 100 | 45,3 | 12,1 | 18,1 | 24,1 |

** The hoppers which form the compartments inside the imhoff tank are in AISI 304 stainless steel

* Cover Slab divided into two parts

The data reported is purely indicative

| Article Code |

Dimensions with lt. for P.E. |

Usable Volume (Sed.+Dig.) (lt) |

External Dimensions Imhoff Tank (cm) |

Tank Weight (ql) |

Cover slab weight (ql) | ||||||

| lt.185 for P.E. | lt.200 for P.E. | lt.250 for P.E. | Width | Length | Height | h. 10 cm (B125) |

h. 15 cm (C250) |

h. 20 cm (D400) |

|||

| IMHOFF1400 | 6 | 6 | 5 | 1.250 | 125 | 130 | 130 | 15,7 | 4,0 | 6,1 | 8,1 |

| IMHOFF2000A | 10 | 10 | 8 | 2.000 | 125 | 180 | 130 | 20,0 | 5,6 | 8,4 | 11,2 |

| IMHOFF3000 | 14 | 13 | 10 | 2.600 | 175 | 180 | 130 | 25,2 | 7,8 | 11,7 | 15,6 |

** The hoppers which form the compartments inside the imhoff tank are in AISI 304 stainless steel

* Cover Slab divided into two parts

The data reported is purely indicative

| Article Code |

Dimensions with lt. for P.E. |

Usable Volume (Sed.+Dig.) (lt) |

External Dimensions Imhoff Tank (cm) |

Tank Weight (ql) |

Cover slab weight (ql) | ||||||

| lt.185 for P.E. | lt.200 for P.E. | lt.250 for P.E. | Width | Length | Height | h. 10 cm (B125) |

h. 15 cm (C250) |

h. 20 cm (D400) |

|||

| IMHOFF1700 | 8 | 7 | 6 | 1.500 | 125 | 130 | 150 | 17,2 | 4,0 | 6,1 | 8,1 |

| IMHOFF-MK1B | 9 | 8 | 6 | 1.700 | 120 | 170 | 150 | 29,0 | 5,0 | 8,0 | 10,0 |

| IMHOFF2500 | 12 | 11 | 9 | 2.250 | 125 | 180 | 150 | 21,8 | 5,6 | 8,4 | 11,2 |

| IMHOFF-MK2B | 12 | 11 | 9 | 2.300 | 120 | 220 | 150 | 36,0 | 7,0 | 10,0 | 13,0 |

| IMHOFF-MK3B | 15 | 14 | 11 | 2.900 | 120 | 270 | 150 | 42,0 | 8,0 | 12,0 | 16,0 |

| IMHOFF3500 | 17 | 15 | 12 | 3.150 | 175 | 180 | 150 | 27,3 | 7,8 | 11,7 | 15,6 |

| IMHOFF-MK4B | 18 | 17 | 13 | 3.400 | 120 | 320 | 150 | 48,0 | 10,0 | 14,0 | 19,0 |

| IMHOFF4900A | 21 | 20 | 16 | 4.000 | 180 | 240 | 150 | 52,1 | 10,7 | 16,1 | 21,5 |

| IMHOFF6500 | 27 | 25 | 20 | 5.000 | 180 | 300 | 150 | 62,1 | 13,4 | 20,1 | 26,8 |

| IMHOFF7000 | 29 | 27 | 21 | 5.450 | 180 | 320 | 150 | 65,5 | 14,3 | 21,5 | 28,6 |

| IMHOFF7500A | 34 | 32 | 25 | 6.400 | 180 | 370 | 150 | 73,7 | 16,5 | 24,8 | 33,1 |

| IMHOFF7900C | 34 | 32 | 25 | 6.400 | 246 | 270 | 150 | 72,5 | 16,5 | 24,7 | 33,0 |

| IMHOFF7800 | 37 | 35 | 28 | 7.000 | 180 | 420 | 150 | 82,0 | 18,8 | 28,2 | 37,6 |

| IMHOFF9000B | 43 | 40 | 32 | 8.000 | 180 | 470 | 150 | 90,4 | 21,0 | 31,5 | 42,0 |

| IMHOFF9000A | 43 | 40 | 32 | 8.000 | 246 | 320 | 150 | 82,5 | 19,6 | 29,3 | 39,1 |

| IMHOFF10500C | 48 | 45 | 36 | 9.000 | 180 | 520 | 150 | 98,7 | 23,3 | 34,9 | 46,5 |

| IMHOFF11000 | 54 | 50 | 40 | 10.000 | 180 | 570 | 150 | 107,0 | 25,5 | 38,2 | 51,0 |

** The hoppers which form the compartments inside the imhoff tank are in AISI 304 stainless steel

* Cover Slab divided into two parts

The data reported is purely indicative

| Article Code |

Dimensions with lt. for P.E. |

Usable Volume (Sed.+Dig.) (lt) |

External Dimensions Imhoff Tank (cm) |

Tank Weight (ql) |

Cover slab weight (ql) | ||||||

| lt.185 for P.E. | lt.200 for P.E. | lt.250 for P.E. | Width | Length | Height | h. 10 cm (B125) |

h. 15 cm (C250) |

h. 20 cm (D400) |

|||

| IMHOFF3000A | 13 | 12 | 10 | 2.500 | 125 | 180 | 200 | 39,4 | 5,6 | 8,4 | 11,2 |

| IMHOFF4900 | 21 | 20 | 16 | 4.000 | 180 | 180 | 200 | 52,4 | 8,0 | 12,1 | 16,1 |

| IMHOFF6400A | 27 | 25 | 20 | 5.000 | 180 | 220 | 200 | 60,9 | 9,8 | 14,8 | 19,7 |

| IMHOFF7900A | 34 | 32 | 25 | 6.400 | 180 | 270 | 200 | 70,6 | 12,1 | 18,1 | 24,1 |

| IMHOFF8000 | 41 | 38 | 30 | 7.700 | 246 | 220 | 200 | 74,6 | 13,4 | 20,2 | 26,9 |

| IMHOFF9000 | 43 | 40 | 32 | 8.000 | 180 | 320 | 200 | 80,1 | 14,3 | 21,5 | 28,6 |

| IMHOFF10500 | 48 | 45 | 36 | 9.000 | 180 | 370 | 200 | 89,6 | 16,5 | 24,8 | 33,1 |

| IMHOFF10500A | 48 | 45 | 36 | 9.000 | 246 | 270 | 200 | 86,1 | 16,5 | 24,7 | 33,0 |

| IMHOFF12000 | 55 | 51 | 41 | 10.250 | 180 | 420 | 200 | 101,5 | 18,8 | 28,2 | 37,6 |

| IMHOFF13000 | 62 | 57 | 46 | 11.520 | 180 | 470 | 200 | 111,1 | 21.0 | 31,5 | 42,0 |

| IMHOFF13000A | 62 | 57 | 46 | 11.520 | 246 | 320 | 200 | 97,5 | 19,6 | 29,4 | 39,1 |

| IMHOFF15000 | 68 | 63 | 51 | 12.750 | 180 | 520 | 200 | 120,7 | 23,3 | 34,9 | 46,5 |

| IMHOFF15000A | 68 | 63 | 51 | 12.750 | 246 | 370 | 200 | 109,0 | 22,6 | 33,9 | 45,2 |

| IMHOFF16500 | 78 | 72 | 58 | 14.500 | 180 | 570 | 200 | 130,3 | 25,5 | 38,2 | 51,0 |

| IMHOFF16500A | 78 | 72 | 58 | 14.500 | 246 | 420 | 200 | 120,5 | 25,7 | 38,5 | 51,3 |

| IMHOFF19000 | 89 | 82 | 66 | 16.530 | 246 | 470 | 200 | 136,1 | 28,7 | 43,1 | 57,4 |

| IMHOFF21000 | 95 | 88 | 70 | 17.630 | 246 | 520 | 200 | 147,5 | 31,8 | 47,7 | 63,6 |

| IMHOFF23000 | 102 | 94 | 75 | 18.900 | 246 | 570 | 200 | 159,0 | 34,8 | 52,2 | 69,7 |

| IMHOFF26000 | 129 | 120 | 96 | 24.000 | 246 | 620 | 200 | 170,5 | 37,7 * | 56,8 * | 75,8 * |

| IMHOFF30000 | 140 | 130 | 104 | 26.000 | 246 | 720 | 200 | 197,7 | 44,0 * | 66,0 * | 88,0 * |

| IMHOFF34000 | 153 | 141 | 113 | 28.340 | 246 | 820 | 200 | 220,6 | 50,1 * | 75,2 * | 100,2 * |

| IMHOFF36000 | 165 | 153 | 122 | 30.700 | 246 | 870 | 200 | 232,1 | 53,2 * | 79,7 * | 106,3 * |

| IMHOFF38000 | 178 | 165 | 132 | 33.000 | 246 | 920 | 200 | 243,5 | 56,2 * | 84,3 * | 112,4 * |

| IMHOFF40000 | 191 | 177 | 141 | 35.430 | 246 | 970 | 200 | 259,2 | 59,3 * | 88,9 * | 118,5 * |

| IMHOFF44000 | 204 | 189 | 151 | 37.800 | 246 | 1070 | 200 | 254,3 | 65,4 * | 98,1 * | 130,8 * |

| IMHOFF46000 | 217 | 200 | 160 | 40.150 | 246 | 1120 | 200 | 264,5 | 68,4 * | 102,7 * | 136,9 * |

** The hoppers which form the compartments inside the imhoff tank are in AISI 304 stainless steel

* Cover Slab divided into two parts

The data reported is purely indicative

| Article Code |

Dimensions with lt. for P.E. |

Usable Volume (Sed.+Dig.) (lt) |

External Dimensions Imhoff Tank (cm) |

Tank Weight (ql) |

Cover slab weight (ql) | ||||||

| lt.185 for P.E. | lt.200 for P.E. | lt.250 for P.E. | Width | Length | Height | h. 10 cm (B125) |

h. 15 cm (C250) |

h. 20 cm (D400) |

|||

| IMHOFF-MK1C | 13 | 12 | 10 | 2.500 | 120 | 170 | 205 | 37,0 | 5,0 | 8,0 | 10,0 |

| IMHOFF-MK2C | 18 | 17 | 13 | 3.400 | 120 | 220 | 205 | 45,0 | 7,0 | 10,0 | 13,0 |

| IMHOFF-MK3C | 22 | 21 | 16 | 4.200 | 120 | 270 | 205 | 52,0 | 8,0 | 12,0 | 16,0 |

| IMHOFF-MK4C | 27 | 25 | 20 | 5.100 | 120 | 320 | 205 | 60,0 | 10,0 | 14,0 | 19,0 |

** The hoppers which form the compartments inside the imhoff tank are in AISI 304 stainless steel

* Cover Slab divided into two parts

The data reported is purely indicative

| Article Code |

Dimensions with lt. for P.E. |

Usable Volume (Sed.+Dig.) (lt) |

External Dimensions Imhoff Tank (cm) |

Tank Weight (ql) |

Cover slab weight (ql) | ||||||

| lt.185 for P.E. | lt.200 for P.E. | lt.250 for P.E. | Width | Length | Height | h. 10 cm (B125) |

h. 15 cm (C250) |

h. 20 cm (D400) |

|||

| IMHOFF12500 | 57 | 52 | 42 | 10.580 | 180 | 370 | 230 | 99,3 | 16,5 | 24,8 | 33,1 |

| IMHOFF12500A | 57 | 53 | 42 | 10.680 | 246 | 270 | 230 | 94,0 | 16,5 | 24,7 | 33,0 |

** The hoppers which form the compartments inside the imhoff tank are in AISI 304 stainless steel

* Cover Slab divided into two parts

The data reported is purely indicative

| Article Code |

Dimensions with lt. for P.E. |

Usable Volume (Sed.+Dig.) (lt) |

External Dimensions Imhoff Tank (cm) |

Tank Weight (ql) |

Cover slab weight (ql) | ||||||

| lt.185 for P.E. | lt.200 for P.E. | lt.250 for P.E. | Width | Length | Height | h. 10 cm (B125) |

h. 15 cm (C250) |

h. 20 cm (D400) |

|||

| IMHOFF2500A | 12 | 11 | 9 | 2.250 | 125 | 130 | 250 | 37,7 | 4,0 | 6,1 | 8,1 |

| IMHOFF4000 | 19 | 18 | 14 | 3.600 | 125 | 180 | 250 | 46,6 | 5,6 | 8,4 | 11,2 |

| IMHOFF6000 | 28 | 26 | 21 | 5.300 | 175 | 180 | 250 | 65,3 | 7,8 | 11,7 | 15,6 |

| IMHOFF7500 | 34 | 32 | 25 | 6.400 | 180 | 220 | 250 | 74,9 | 9,8 | 14,8 | 19,7 |

| IMHOFF7900B | 37 | 35 | 28 | 7.000 | 180 | 270 | 250 | 83,8 | 12,1 | 18,1 | 24,1 |

| IMHOFF10500B | 48 | 45 | 36 | 9.000 | 246 | 220 | 250 | 86,4 | 13,4 | 20,2 | 26,9 |

| IMHOFF13000B | 64 | 60 | 48 | 12.000 | 246 | 270 | 250 | 99,2 | 16,5 | 24,7 | 33,0 |

| IMHOFF16000 | 81 | 75 | 60 | 15.000 | 246 | 320 | 250 | 111,8 | 19,6 | 29,3 | 39,1 |

| IMHOFF19000B | 89 | 82 | 66 | 16.530 | 180 | 520 | 250 | 141,5 | 23,5 | 34,9 | 46,5 |

| IMHOFF19000A | 89 | 82 | 66 | 16.530 | 246 | 370 | 250 | 124,6 | 22,6 | 33,9 | 45,2 |

| IMHOFF21000B | 95 | 88 | 70 | 17.630 | 180 | 570 | 250 | 152,6 | 25,5 | 38,2 | 51,0 |

| IMHOFF21000A | 102 | 94 | 75 | 18.900 | 246 | 420 | 250 | 137,3 | 25,7 | 38,5 | 51,3 |

| IMHOFF24000 | 114 | 106 | 85 | 21.260 | 246 | 470 | 250 | 155,5 | 28,7 | 43,1 | 57,4 |

| IMHOFF26000A | 129 | 120 | 96 | 24.000 | 246 | 520 | 250 | 168,2 | 31,8 | 47,7 | 63,6 |

| IMHOFF30000A | 140 | 130 | 104 | 26.000 | 246 | 570 | 250 | 181,0 | 34,8 | 52,2 | 69,7 |

| IMHOFF32000A | 153 | 141 | 113 | 28.340 | 246 | 620 | 250 | 193,7 | 37,9 * | 56,8 * | 75,8 * |

| IMHOFF35000 | 165 | 153 | 122 | 30.700 | 246 | 670 | 250 | 206,4 | 40,9 * | 61,4 * | 81,9 * |

| IMHOFF37000 | 178 | 165 | 132 | 33.000 | 246 | 720 | 250 | 224,5 | 44,0 * | 66,0 * | 88,0 * |

| IMHOFF40000A | 191 | 177 | 141 | 35.430 | 246 | 770 | 250 | 237,3 | 47,1 * | 70,6 * | 94,1 * |

| IMHOFF42000A | 204 | 189 | 151 | 37.800 | 246 | 820 | 250 | 250,0 | 50,1 * | 75,2 * | 100,2 * |

| IMHOFF45000 | 217 | 200 | 160 | 40.150 | 246 | 870 | 250 | 262,8 | 53,2 * | 79,7 * | 106,3 * |

| IMHOFF48000 | 229 | 212 | 170 | 42.500 | 246 | 920 | 250 | 275,5 | 56,2 * | 84,3 * | 112,4 * |

| IMHOFF50000 | 243 | 225 | 180 | 45.000 | 246 | 970 | 250 | 293,7 | 59,3 * | 88,9 * | 118,5 * |

| IMHOFF52000 | 255 | 236 | 189 | 47.250 | 246 | 1020 | 250 | 279,8 ** | 62,3 * | 93,5 * | 124,7 * |

| IMHOFF55000 | 268 | 248 | 198 | 49.600 | 246 | 1070 | 250 | 291,2 ** | 65,4 * | 98,1 * | 130,8 * |

| IMHOFF57000 | 281 | 260 | 208 | 52.000 | 246 | 1120 | 250 | 302,7 ** | 68,4 * | 102,7 * | 136,9 * |

| IMHOFF60000 | 293 | 271 | 217 | 54.350 | 246 | 1170 | 250 | 319,5 ** | 71,5 * | 107,2 * | 143,0 * |

| IMHOFF64000 | 306 | 283 | 226 | 56.700 | 246 | 1220 | 250 | 331,0 ** | 74,5 * | 111,8 * | 149,1 * |

| IMHOFF67000 | 318 | 295 | 236 | 59.000 | 246 | 1270 | 250 | 342,4 ** | 77,6 * | 116,4 * | 155,2 * |

** The hoppers which form the compartments inside the imhoff tank are in AISI 304 stainless steel

* Cover Slab divided into two parts

The data reported is purely indicative

| Article Code |

Dimensions with lt. for P.E. |

Usable Volume (Sed.+Dig.) (lt) |

External Dimensions Imhoff Tank (cm) |

Tank Weight (ql) |

Cover slab weight (ql) | ||||||

| lt.185 for P.E. | lt.200 for P.E. | lt.250 for P.E. | Width | Length | Height | h. 10 cm (B125) |

h. 15 cm (C250) |

h. 20 cm (D400) |

|||

| IMHOFF60000A | 297 | 275 | 220 | 55.000 | 246 | 970 | 300 | 304,8 ** | 59,3 * | 88,9 * | 118,5 * |

| IMHOFF63000 | 313 | 290 | 232 | 58.000 | 246 | 1020 | 300 | 318,1 ** | 62,3 * | 93,5 * | 124,7 * |

** The hoppers which form the compartments inside the imhoff tank are in AISI 304 stainless steel

* Cover Slab divided into two parts

The data reported is purely indicative

Marche Region Imhoff Tanks

1 draining a year

Dimensioning: D.P.C.R. Resolution No. 145 of 26/01/2010 Marche Water Protection Plan

100 lt/P.E. for the sedimentation compartment and 150 lt/P.E. for the digestion compartment.

drain twice a year

Dimensioning: D.P.C.R. Resolution No. 145 of 26/01/2010 Marche Water Protection Plan

50 lt/P.E. for the sedimentation compartment and 135 lt/P.E. for the digestion compartment.