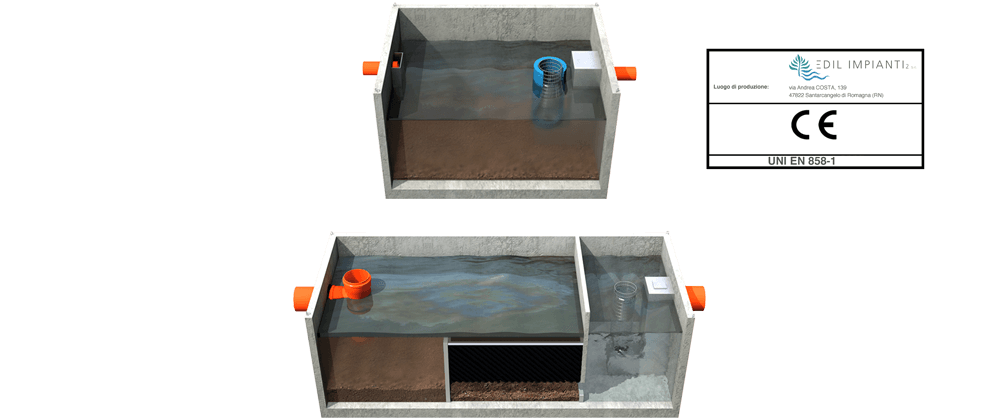

CE Oil skimmer separator Coalescence Filter Lamellar Pack

Prefabricated in reinforced concrete compliant with the UNI EN 858-1 standard requirements

with CE mark as per Regulation No. 305/2011 - Oil separator I class - certified by a third body with declaration of performance (DoP)

Features and operating principle

The precast concrete oil skimmer separator for rainwater with coalescence filter and automatic locking system have a specific function, i.e., to naturally separate without any chemical additives - sand, mineral oils and hydrocarbons in the inflowing rainwater, i.e., first rainwater or floor washing water.

Rainwater collection from squares and courtyards can mainly be made in two ways: point collection or linear collection.

In systems equipped with oil separators, wastewater remains in the main compartment, where floating materials are (oil, hydrocarbons, etc.), which having a lower density thank water, are collected on the surface of the liquid mass and compose a oil layer with an increasingly higher thickness based on the incoming concentration of these materials.

Reference regulations

The Decree Law 152/99 and following amendments/integrations sets out an acceptable oil/hydrocarbons wastewater concentration lower than 10 mg/l for each drain into the sewerage system and lower thank 10 mg/l for each drain into surface water.

Starting from July 1st, 2013, the EU 305/2011 regulation is binding and provides for harmonized conditions for the sale of construction products, thus replacing the old European Directive 89/106 (CPD). Construction products falling within the scope of a harmonized standard and/or compliant with a European technical assessment, as per the Construction Products Regulation 305/2011/UE, must be equipped with a Declaration of Performance (DoP) (replacing the Declaration of Conformity) and CE marking.

EDILIMPIANTI 2 srl manufactures its systems for light liquid separation in compliance with the UNI EN 858 standard, specifically indicating "planning, performance and product test, CE marking and control" criteria, utmost care for its quality level which made it possible for Edil Impianti 2 srl to obtain the independent third body certification as stated in Appendix D chapter D.2.1 of the UNI EN 858 standard.

Thus, we can guarantee:

1. Manufacturer's license validity check;

2. Initial Type Testing (ITT) check;

3. Control outcome conformity check made according to the UNI EN 858 standard.

Supply specifications

Delivery and installation of an underground static oil separator/light liquid separator manufactured in DECLARED SERIES with CE marking, compliant with the UNI EN 858-1 standard as per Regulation No. 305/2011 Class I Separators - Certified by a third body with Declaration of Performance (DoP), mod. DISCE-____ with external dimensions cm.____x____x h____, flow rate ___ lt/sec, with Coalescence filter Refill Modules/Lamellar Packs, manufactured by EDIL IMPIANTI 2 S.r.l. with UNI EN ISO 9001 and ISO 45001 management system made of monoblock vibrated concrete, reinforced with vertical pillars and stainless steel horizontal beams, with CE-certified materials, concrete in compressive strength class C45/55 (RCK >55 N/mm²), internal improved-adhesion steel reinforcements checked in our plant, GREESMIX5® steel fibers (patent No. 0001421398 issued by the Ministry for Economic Development) and electro-welded square mesh B450C, with certification of CHEMICAL RESISTANCE and REACTION TO FIRE (Class A1) issued by an external body based on UNI EN standards.

The Static Oil Separator/Light Liquid Separator with CE marking is supplied with:

- inlet/outlet portholes;

- inlet connection with gasket in elastomeric rubber and stilling baffle in AISI 304 stainless steel;

- sedimentation/oil flotation and de-oiling compartment;

- partition wall/s in vibrated reinforced concrete;

- floating shutter (automatic shutter system) entirely made of AISI 304 stainless steel;

- internal walls coated with epoxy paint modified with hydrocarbon resins for acid-proofing of concrete surfaces, outer wall side coated with suitable waterproofing products.

Static Oil Separator Dimensions / Light Liquid Separator with Modules/ Lamellar Pack coalescence Refill filter

Download E.U. dimensions

Select Article Code to access the E.U. dimensions for the product.

Article Code

Data Sheet Download

Select Article Code to access the Data Sheet for the product.

Article Code

| Article Code |

Range NS (lt/sec) |

Sludge Load Volume (mc) |

Separator water Volume (lt) |

Light liquids storage capacity (lt) |

Oil separator External Dimensions (cm) |

Pipes Diameter (mm) |

Tank Weight (ql) |

Cover slab weight (ql) | |||

| h. 10 cm (B125) |

h. 15 cm (C250) |

h. 20 cm (D400) |

|||||||||

| DISCE1C-FC | 1 | 0,30 | 581 | 407 | 125X130XH100 | 125 | 11,8 | 4,0 | 6,1 | 8,1 | |

| DISCE1,5C-FC | 1,5 | 0,45 | 1466 | 422 | 125X130XH150 | 125 | 15,6 | 4,0 | 6,1 | 8,1 | |

| DISCE2C-FC | 2 | 0,60 | 2127 | 608 | 125X180XH150 | 125 | 19,6 | 5,6 | 8,4 | 11,2 | |

| DISCE3C-FC | 3 | 0,90 | 3116 | 887 | 175X180XH150 | 125 | 23,8 | 7,8 | 11,7 | 15,6 | |

| DISCE4-8C-FC | 4-8 | 2,40 | 3928 | 1341 | 180X240XH150 | 160 | 47,1 | 10,7 | 16,1 | 21,5 | |

| DISCE4Y8C-FC | 4-8 | 2,40 | 4214 | 967 | 180X180XH200 | 160 | 51,2 | 8,0 | 12,1 | 16,1 | |

| DISCE10A-PL | 10 | 1,00 | 6400 | 600 | 180X270XH200 | 200 | 63,9 | 9,8 | 14,8 | 19,7 | |

| DISCE10B-PL | 10 | 2,00 | 7168 | 672 | 180X300XH200 | 200 | 77,4 | 13,4 | 20,1 | 26,8 | |

| DISCE10C-PL | 10 | 3,00 | 7680 | 720 | 180X320XH200 | 200 | 80,8 | 14,3 | 21,5 | 28,6 | |

| DISCE20A-PL | 20 | 2,00 | 6989 | 672 | 180X300XH200 | 250 | 77,4 | 13,4 | 20,1 | 26,8 | |

| DISCE20B-PL | 20 | 4,00 | 8736 | 840 | 180X370XH200 | 250 | 89,3 | 16,5 | 24,8 | 33,1 | |

| DISCE20C-PL | 20 | 6,00 | 9984 | 960 | 180X420XH200 | 250 | 97,7 | 18,8 | 28,2 | 37,6 | |

| DISCE30A-PL | 30 | 3,00 | 11752 | 848 | 246X270XH250 | 250 | 109,4 | 16,5 | 24,7 | 33,0 | |

| DISCE30B-PL | 30 | 6,00 | 14102 | 1017 | 246X320XH250 | 250 | 120,6 | 19,6 | 29,3 | 39,1 | |

| DISCE30C-PL | 30 | 9,00 | 16453 | 1187 | 246X370XH250 | 250 | 131,7 | 22,6 | 33,9 | 45,2 | |

| DISCE40A-PL | 40 | 4,00 | 13560 | 1017 | 246X320XH250 | 300 | 126,5 | 19,6 | 29,3 | 39,1 | |

| DISCE40B-PL | 40 | 8,00 | 15820 | 1187 | 246X370XH250 | 300 | 137,8 | 22,6 | 33,9 | 45,2 | |

| DISCE40C-PL | 40 | 12,00 | 18080 | 1356 | 246X420XH250 | 300 | 149,2 | 25,7 | 38,5 | 51,3 | |

| DISCE50A-PL | 50 | 5,00 | 13628 | 1017 | 246X320XH250 | 300 | 125,1 | 19,6 | 29,3 | 39,1 | |

| DISCE50B-PL | 50 | 10,00 | 18170 | 1356 | 246X420XH250 | 300 | 147,4 | 25,7 | 38,5 | 51,3 | |

| DISCE50C-PL | 50 | 15,00 | 20442 | 1526 | 246X470XH250 | 300 | 164,0 | 28,7 | 43,1 | 57,4 | |

| DISCE60A-PL | 60 | 6,00 | 13696 | 1017 | 246X320XH250 | 300 | 125,1 | 19,6 | 29,3 | 39,1 | |

| DISCE60B-PL | 60 | 12,00 | 18261 | 1356 | 246X420XH250 | 300 | 147,4 | 25,7 | 38,5 | 51,3 | |

| DISCE60C-PL | 60 | 18,00 | 22826 | 1695 | 246X520XH250 | 300 | 175,2 | 31,8 | 47,7 | 63,6 | |

| DISCE70A-PL | 70 | 7,00 | 20747 | 1526 | 246X470XH250 | 300 | 164,0 | 28,7 | 43,1 | 57,4 | |

| DISCE70B-PL | 70 | 14,00 | 25357 | 1865 | 246X570XH250 | 300 | 186,4 | 34,8 | 52,2 | 69,7 | |

| DISCE70C-PL | 70 | 21,00 | 29968 | 2204 | 246X670XH250 | 300 | 208,7 | 40,9* | 61,4* | 81,9* | |

| DISCE80A-PL | 80 | 8,00 | 23165 | 1695 | 246X520XH250 | 300 | 175,2 | 31,8 | 47,7 | 63,6 | |

| DISCE80B-PL | 80 | 16,00 | 27798 | 2034 | 246X620XH250 | 300 | 197,6 | 37,9* | 56,8* | 75,8* | |

| DISCE80C-PL | 80 | 24,00 | 32431 | 2373 | 246X720XH250 | 300 | 225,4 | 44,0* | 66,0* | 88,0* | |

| DISCE90A-PL | 90 | 9,00 | 23278 | 1695 | 246X520XH250 | 300 | 175,2 | 31,8 | 47,7 | 63,6 | |

| DISCE90B-PL | 90 | 18,00 | 27934 | 2034 | 246X620XH250 | 300 | 197,6 | 37,9* | 56,8* | 75,8* | |

| DISCE90C-PL | 90 | 27,00 | 34917 | 2543 | 246X770XH250 | 300 | 236,5 | 47,1* | 70,6* | 94,1* | |

| DISCE100A-PL | 100 | 10,00 | 24176 | 1865 | 246X570XH250 | 400 | 186,4 | 34,8 | 52,2 | 69,7 | |

| DISCE100B-PL | 100 | 20,00 | 28572 | 2204 | 246X670XH250 | 400 | 208,7 | 40,9* | 61,4* | 81,9* | |

| DISCE100C-PL | 100 | 30,00 | 35166 | 2712 | 246X820XH250 | 400 | 247,7 | 50,1* | 75,2* | 100,2* | |

| DISCE120A-PL | 120 | 12,00 | 24363 | 1865 | 246X570XH250 | 400 | 186,4 | 34,8 | 52,2 | 69,7 | |

| DISCE120B-PL | 120 | 24,00 | 31007 | 2373 | 246X720XH250 | 400 | 225,4 | 44,0* | 66,0* | 88,0* | |

| DISCE120C-PL | 120 | 36,00 | 43155 | 3221 | 246X970XH250 | 400 | 286,7 | 59,3* | 88,9* | 118,5* | |

| DISCE150A-PL | 150 | 15,00 | 31434 | 2373 | 246X720XH250 | 400 | 225,4 | 44,0* | 66,0* | 88,0* | |

| DISCE150B-PL | 150 | 30,00 | 42661 | 3221 | 246X970XH250 | 400 | 286,7 | 59,3* | 88,9* | 118,5* | |

| DISCE150C-PL | 150 | 45,00 | 55108 | 4068 | 246X570XH250+ 246X670XH250 |

400 | 163,9+ 208,7 |

34,8+ 40,9* |

52,2+ 61,4* |

69,7+ 81,9* |

|

| DISCE200A-PL | 200 | 20,00 | 42165 | 3051 | 246X920XH250 | 400 | 270,1 | 56,2 | 84,3 | 112,4 | |

| DISCE200B-PL | 200 | 40,0 | 58562 | 4238 | 246X520XH250+ 246X770XH250 |

400 | 152,7+ 236,5 |

31,8+ 47,1 |

47,7+ 70,6 |

63,6+ 94,1 |

|

| DISCE200C-PL | 200 | 60,0 | 74960 | 5424 | 246X720XH250+ 246X920XH250 |

400 | 202,8+ 270,1 |

44,0+ 56,2 |

66,0+ 84,3 |

88,0+ 84,3 |

|

| DISCE250A-PL | 250 | 25,0 | 54813 | 3899 | 246X270XH250+ 246X920XH250 |

400 | 91,4+ 270,1 |

16,5+ 56,2* |

24,7+ 84,3* |

33,0+ 112,4* |

|

| DISCE250B-PL | 250 | 50,0 | 83411 | 5933 | 246X870XH250+ 246X920XH250 |

400 | 236,4+ 270,1 |

53,2*+ 56,2* |

79,7*+ 84,3* |

106,3*+ 112,4* |

|

| DISCE250C-PL | 250 | 75,0 | 109626 | 7797 | 246X720XH250+ 246X720XH250+ 246X920XH250 |

400 | 202,8+ 202,8+ 270,1 |

44,0*+ 44,0*+ 56,2* |

66,0*+ 66,0*+ 84,3* |

88,0*+ 88,0*+ 112,4* |

|

| DISCE300A-PL | 300 | 30,0 | 65212 | 4916 | 246X570XH250+ 246X920XH250 |

500 | 163,9+ 270,1 |

34,8+ 56,2* |

52,2+ 84,3* |

69,7+ 112,4* |

|

| DISCE300B-PL | 300 | 60,0 | 94445 | 7119 | 246X620XH250+ 246X620XH250+ 246X920XH250 |

500 | 175,1+ 175,1+ 270,1 |

37,9*+ 37,9*+ 56,2* |

56,8*+ 56,8*+ 84,3* |

75,8*+ 75,8*+ 112,4* |

|

| DISCE300C-PL | 300 | 90,0 | 130425 | 9831 | 246X1020XH250+ 246X1020XH250+ 246X920XH250 |

500 | 275,3+ 275,3+ 270,1 |

62,3*+ 62,3*+ 56,2* |

93,5*+ 93,5*+ 84,3* |

124,7*+ 124,7*+ 112,4* |

|

* Cover Slab divided into two parts

The data reported is purely indicative

| Sludge quantity types | ||

| A | 100 lt. SLUDGE LOAD | TAll rainwater collection areas where small amounts of silt produced by traffic or similar, i.e., catch basins in fuel storage areas and covered refuelling stations |

| B | 200 lt. SLUDGE LOAD | Refueling stations, hand car washes, component washing, bus wash areas, garage wastewater, vehicle parking areas, power stations, plants and machinery |

| C | 300 lt. SLUDGE LOAD | Washing facilities for construction vehicles, construction machinery, agricultural machinery, washing areas, trucks |

Login:

Login: